Equipment

Precision Tools for Precision Jobs

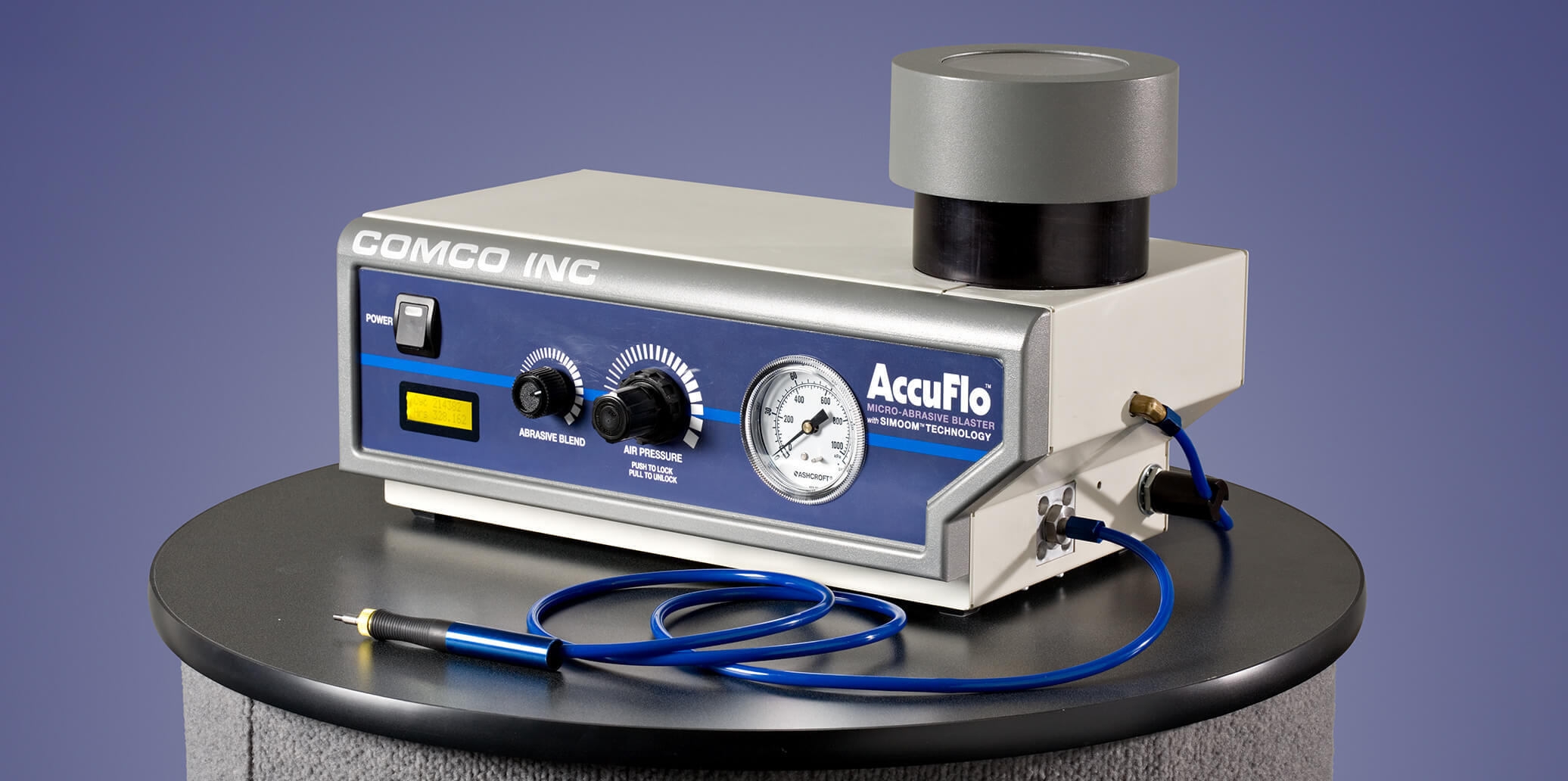

Accuflo

Meet AccuFlo, the newest member of the MicroBlaster family. AccuFlo is tough enough to perform in high-volume production environments but versatile enough for smaller shops.

Learn more about Accuflo

Learn more about Accuflo

ProCenter Plus

ProCenter Plus is our cleanest, quietest blasting center, featuring a spacious work chamber, air dryer, and dust collector in one freestanding unit. ProCenter Plus fits conveniently into any workspace and is ergonomically designed for operator comfort.

Learn more about ProCenter Plus

Learn more about ProCenter Plus

Advanced lathe

If your application requires the combination of precision MicroBlasting and a spindle, Advanced Lathe is your answer.

Learn more about Advanced Lathe

Learn more about Advanced Lathe

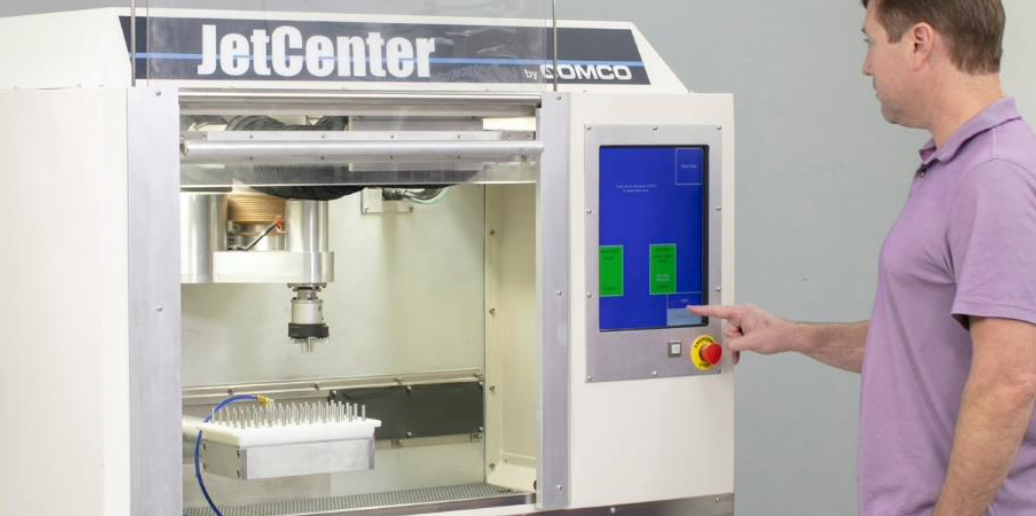

JetCenter

Our largest automated platform, JetCenter is ideally suited for applications that require significant motion in XYZ. Need to integrate external robotics? JetCenter is your answer.

Learn more about JetCenter

Learn more about JetCenter

An abrasive for every surface

There are three components to factor in when selecting abrasive media: particle shape, size, and hardness. A sharp and hard abrasive like aluminum oxide is ideal for working on metals while sodium bicarbonate is better suited for abrading pliable materials. Explore our wide range of abrasive types and sizes to suit your specific application. (Find Abrasive Safety Data Sheets here.)

Abrasive media guide-

Aluminum Oxide

The most common abrasive when cutting is required. Available in the widest range of sizes.

-

Silicon Carbide

The most aggressive abrasive, quickly removes material and deburrs metals.

-

Crushed Glass

This sharp, but less hard abrasive is ideal for light abrading.

-

Sodium Bicarbonate

Primary choice for cutting through polymers–and it’s water-soluble.

-

Glass Bead

Its spherical shape makes it ideal for peening, imparting a satin finish.

-

Walnut Shell

A combination of low hardness and high mass make it useful for more aggressive cleaning of soft materials.

-

Plastic Media

This blocky yet soft abrasive is ideal for deburring or deflashing plastics.

-

Wheat Starch

Our softest abrasive perfect for work on circuit boards and delicate applications.

-

Pumice

A delicate cutting abrasive, good for removing matrix from fossils.

Precision Nozzles

A nozzle is an integral part of any MicroBlasting system, providing focus and acceleration to the abrasive stream. Manufactured from high-grade tungsten carbide, Comco nozzles guarantee the highest level of repeatability with every blast

View Nozzle guide

View Nozzle guide

Legacy Components

Since launching our first MicroBlaster in 1968, Comco has delivered unequaled performance, reliability, and precision. With each new generation, we renew our commitment to design excellence and customer satisfaction.

View Legacy Components

View Legacy Components

Try our process

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a demo