Equipment Updates

AccuFlo Upgrade: The Calibration Cap

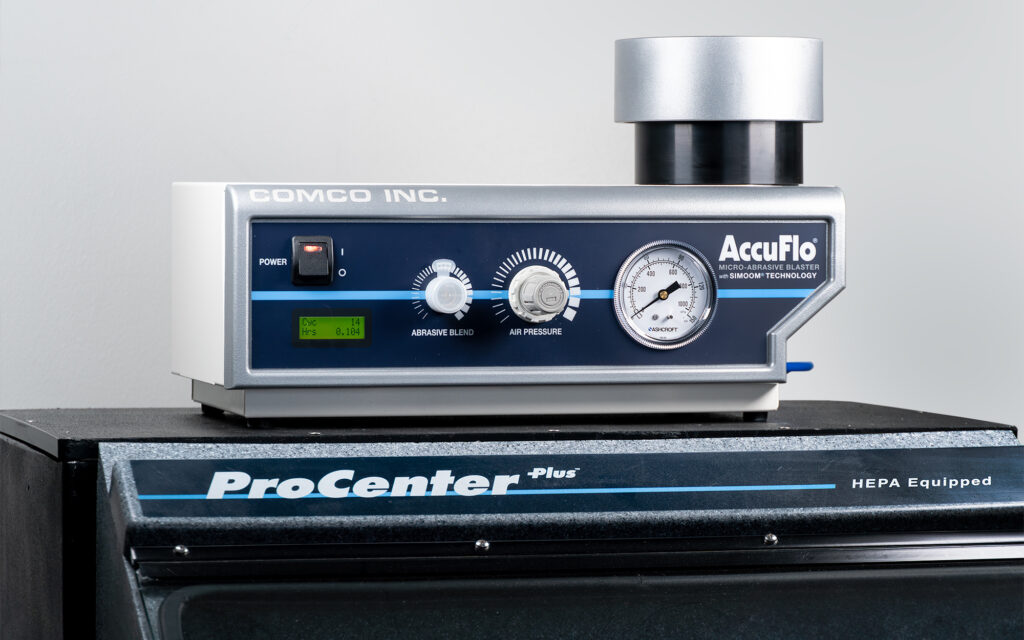

When we introduced the AccuFlo, equipped with the patented Simoom Technology — a redesigned modulator, aerodynamic tank and PowderGate valve — built on 40 years of MicroBlasting, it was an engineering breakthrough, and (we think) pretty close to perfection.

But at Comco, following the principles that got this company started, there’s always room for improvement. As we came to better understand our equipment use in the field, we realized we could make the AccuFlo even better.

Introducing the Calibration Cap

The abrasive blend knob can be a bit of a mystery for many operators and for tightly regulated processes, an unwelcome source of variation. For the majority of our applications, the factory setting is perfect. In cases where calibration between machines is required, the ability to lock down a particular setting is critical.

Our new tamper evident cap ensures that once the unit has been dialed in, any changes to the settings are evident.

Why Use the Calibration Cap?

Around 95% of our applications work best at the factory setting. This is the fully closed position which allows the most abrasive flow through the blaster. The cap avoids accidental adjustment of the abrasive flow. The most common tech support issues are solved by having the operator properly adjust the “old” abrasive blend knob. That means for many users, simply popping the calibration cap on the machine after some quick test blasts is the way to go.

It also allows the applications engineer to have more control over how parts are processed by eliminating the variation that can come from multiple operators using the machine.

Additionally it reduces variation from blaster to blaster. For installations with multiple blasters, they can all be configured identically.

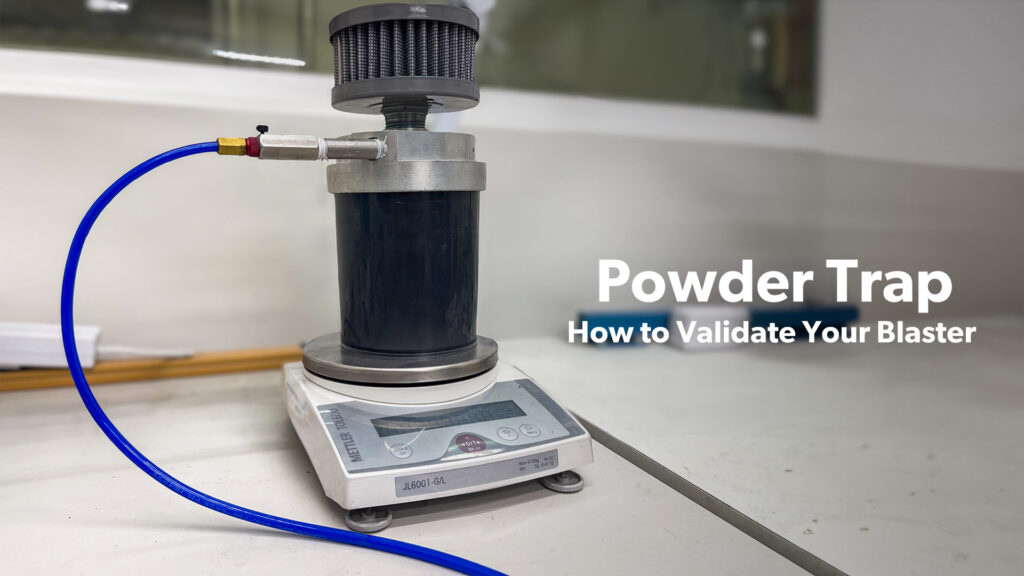

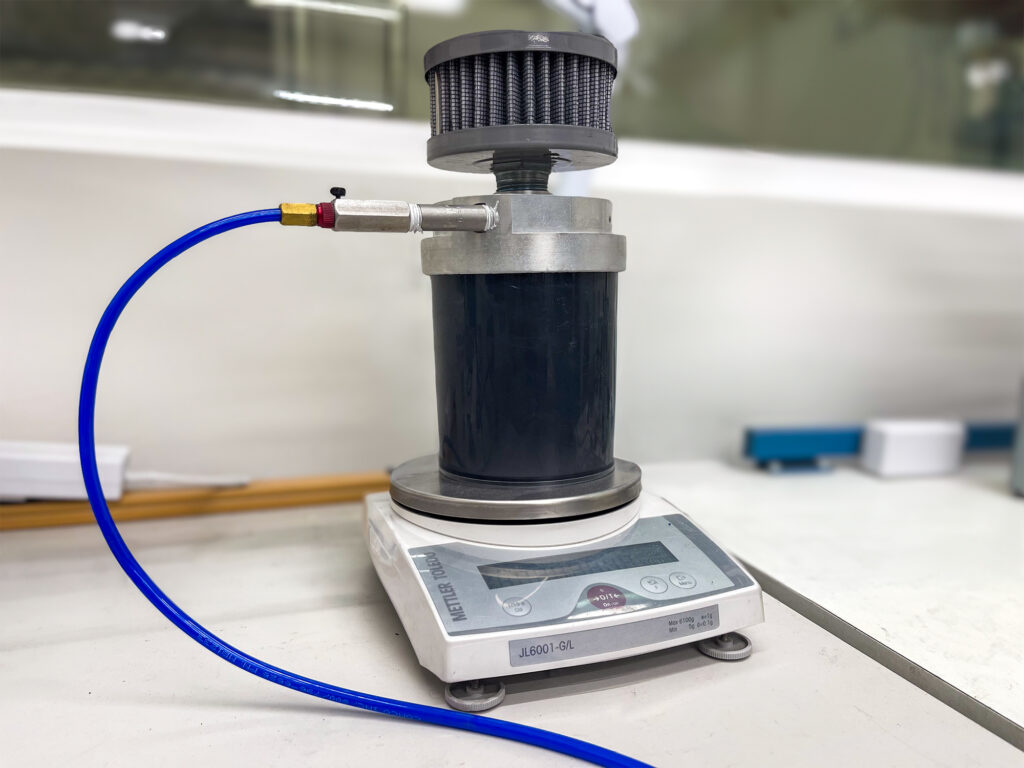

How to Calibrate Your AccuFlo

If you’re in that 5% who benefit from the fine tuning the abrasive blend control offers, the most common method for calibrating your machine is by using our powder trap and scale. By weighing abrasive consumption over a 3 minute period, multiple machines can be set to a consistent abrasive flow. once the process is complete we have included a tamper evident cap for the abrasive blend valve to avoid unwanted or accidental adjustments. The validation process will need to be repeated periodically to compensate for wear inside the blaster.

Final Note:

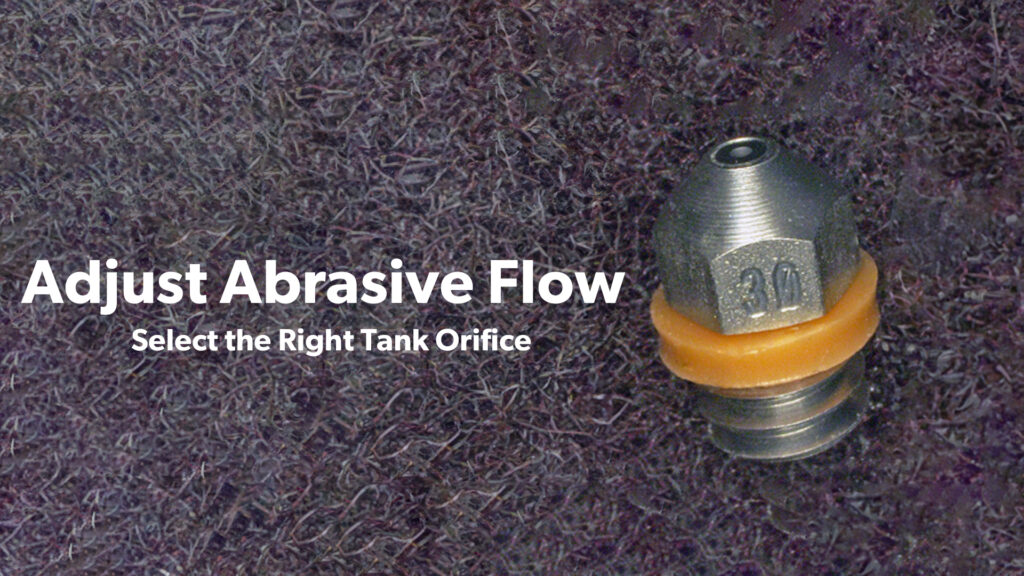

The richness of the abrasive stream is just one of the variables that give flexibility to the MicroBlasting process. To a small degree, it can be adjusted through the abrasive blend control. More substantial changes can be set by changing the tank orifice. If you need help dialing in the process for your application, our Applications Engineers are here to help.

If you would like to convert to your older AccuFlo to use the calibration cap, order: MB1633-2 Calibration Cap Conversion Kit.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.