Case Studies

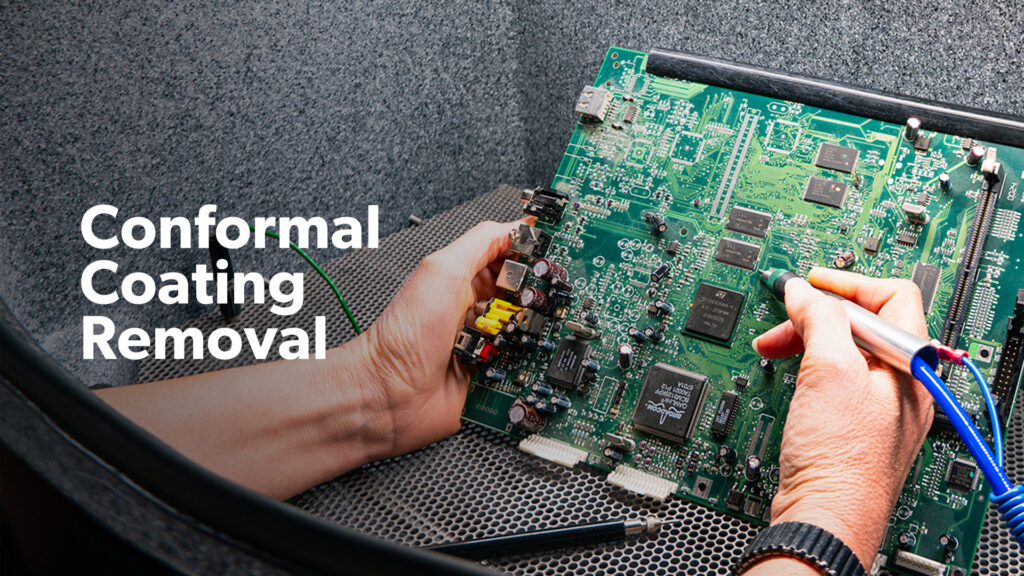

Removing Conformal Coating? Consider Wheat Starch

Why Use Wheat Starch to Remove Conformal Coating?

- Has very soft but slightly sharp particles- the ideal combination for gentle, precise abrading

- Is too mild to present any real risk of damage to the solder mask or underlying components

- Is water soluble and biodegradable

- Smells like fresh-baked bread (Ok, that’s not true, but if it did, we would blast with it all the time!)

Take a look at this quick demo below and see wheat starch in action.

What is Wheat Starch Exactly?

Our wheat starch abrasive media is manufactured by polymerizing and crushing, well, wheat starch. It registers as a 2 on the Mohs scale. Its average particle size is 0.004″ or 100 µ, and its particle shape is blocky and crystalline with shard-like edges.

Wheat Starch is the Safest Choice

A good rule of thumb for abrasive selection is the thicker the coating, the more aggressive the media needed for removal. However, circuit boards are especially delicate, so coating removal must err on the side of caution. We recommend only using soft and mild abrasives for conformal coating removal, and wheat starch is the most gentle. It’s so gentle, that we often start with wheat starch in sample tests and work up. It is particularly effective at removing the following types of material:

- Acrylic

- Parylene

- Silicone

- UV Epoxy

Wheat starch takes longer to remove coating than plastic media and sodium bicarbonate, but the trade-off for speed is safety.

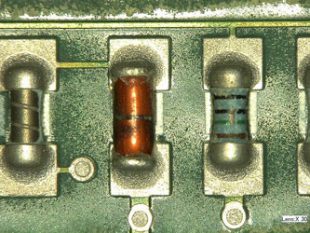

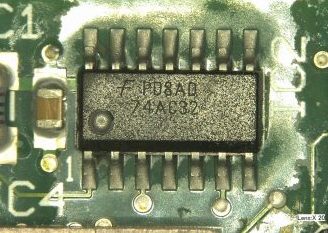

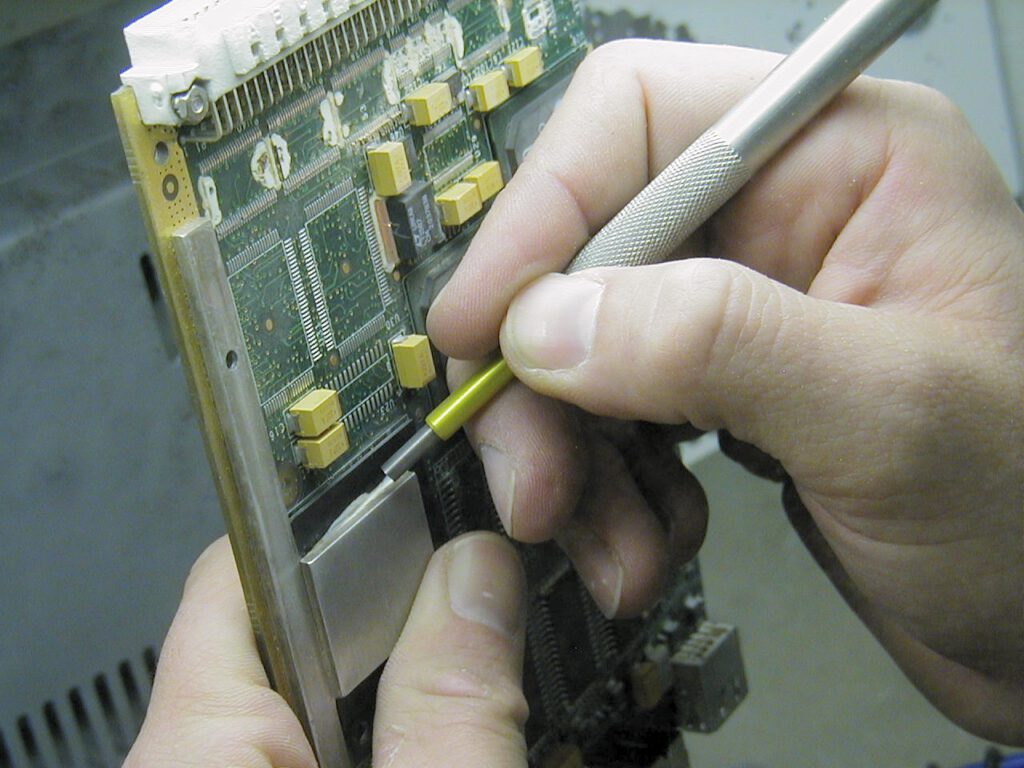

In the examples pictured here, we blasted 100 µ wheat starch at 50-60 psi through a 0.030″ conductive nozzle to remove a thin layer of silicone. The goal was to only reveal select board components for testing.

The white line at the top of example 1 and circling the component in example 2 mark the edge of the blasted area. We were able to get a relatively sharp line of delineation in both examples. (Images are magnified 30x.) We were also able to remove coating in between the pads that extend from the component in example 2.

Why use MicroBlasting to Remove Conformal Coating?

It may be helpful to familiarize yourself with the whys and hows of MicroBlasting as a removal method.

Highlights

- Learn why MicroBlasting works

- Learn which abrasives work best for each type of coating

- Review the features of the ProCenter Plus™ with ESD Control

- See what tools are available to speed up your processing time, like the Dual Tank MicroBlaster®, the Magnifier, etc

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.