Case Studies

Divesting Bridges and Crowns Just Got Easier

Traditionally, divesting bridges and crowns is a two-step process performed with two different abrasives and our Dual-Tank MicroBlaster®. Operators start with aluminum oxide to remove the bulk of the investment casting. Then, they switch to glass bead, to remove investment casting touching the bridge or crown. Glass bead has a spherical shape and is not sharp enough to damage the integrity of the bridge and crown.

We recently discovered something quite cool…

One (Abrasive) is Enough

We now know: the two-abrasives approach may include one abrasive too many.

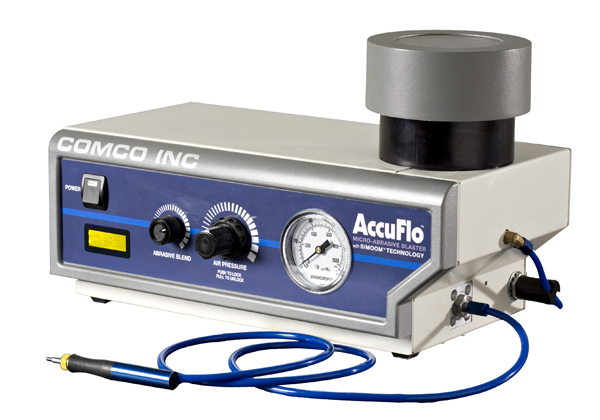

Our AccuFlo® MicroBlaster, when combined with our Hi/Performance nozzle, provides enough velocity to remove all of the investment casting around a dental bridge and crown using glass bead abrasive. Yep, you read that right: ALL of the investment casting. This is kind of big news for dental labs.

One (Tank) is Enough

Not only does the single-abrasive approach simplify and streamline the removal process, it also requires fewer parts. A second tank is not necessary, which means one less tank system to operate, clean and replace. That’s one less nozzle, one less abrasive hose—you get the idea.

Watch Divestment with the AccuFlo

What’s a discovery without a little video evidence? See how AccuFlo® turns a traditionally two-abrasive process into a single abrasive process.

Tool Breakdown

The following MicroBlasting equipment, accessories and settings used in the application depicted above.

- Equipment: The AccuFlo® and the ProCenter Plus™

- Nozzle: Hi/Performance nozzle in ComfortGrip Handpiece

- Abrasive: 50 µ Glass Bead

- Blast Pressure: 65 psi*

*Higher pressure can be used during the initial coarse removal process to speed it up.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.