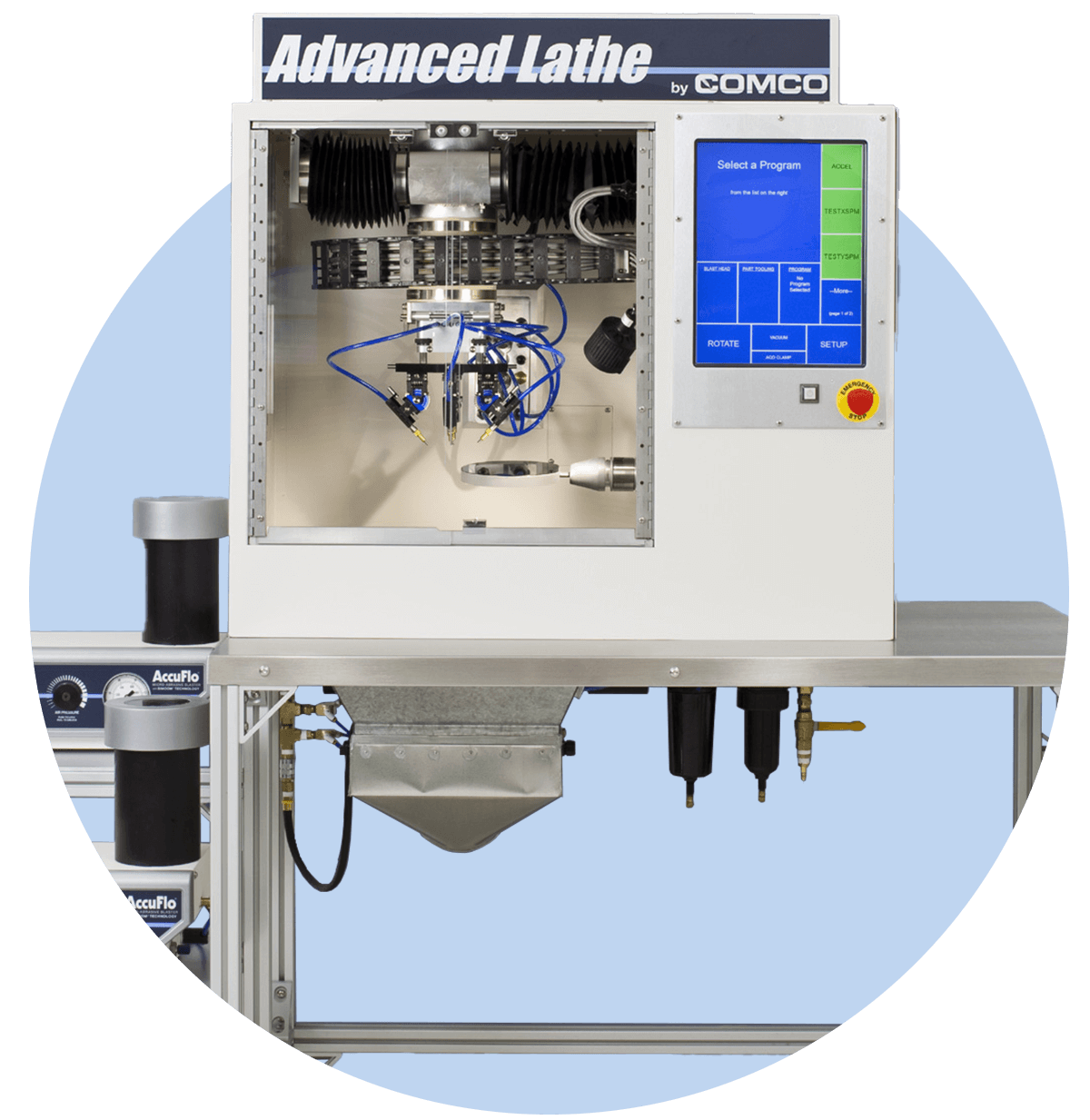

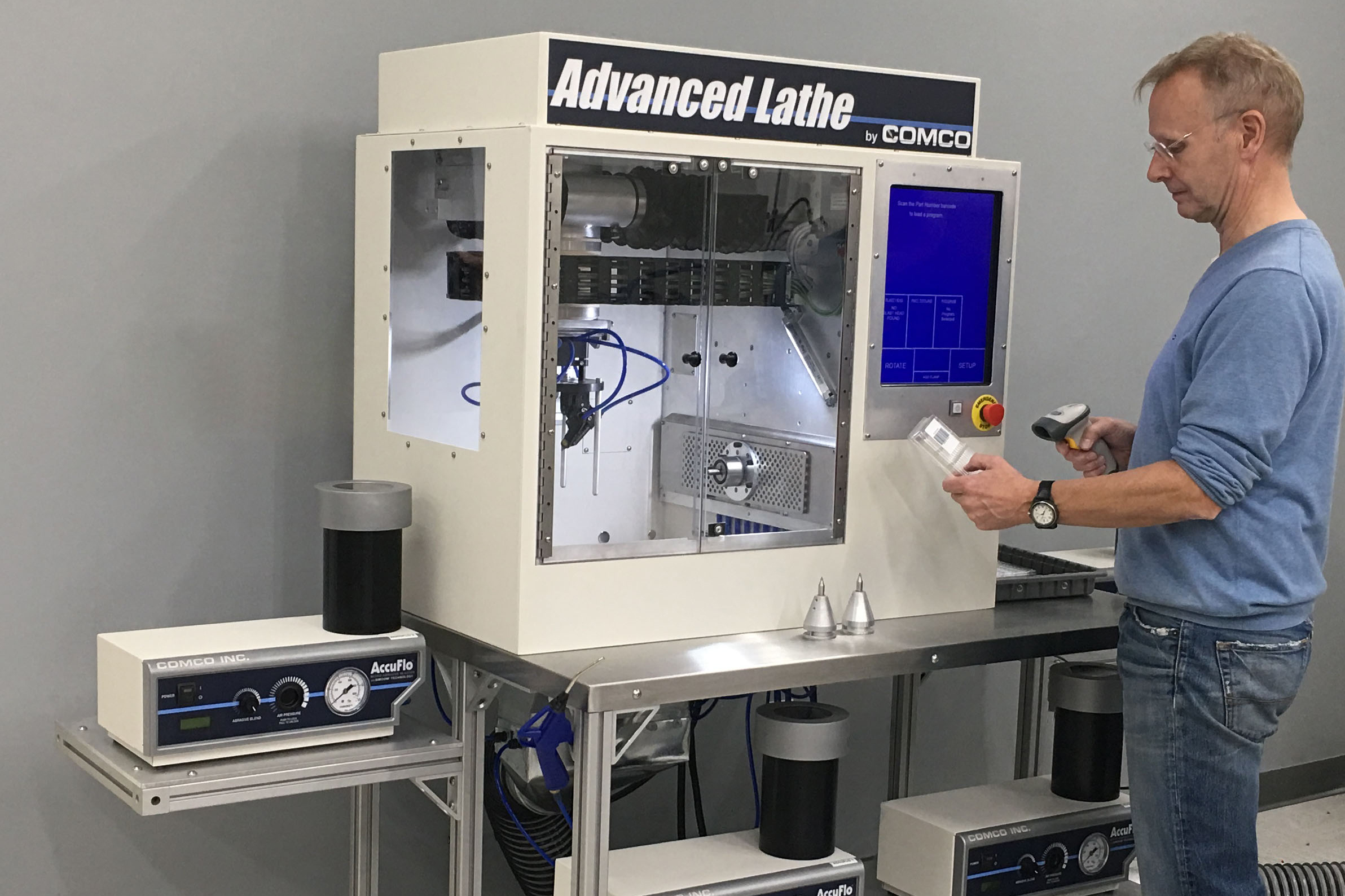

Advanced Lathe

Our proven platform for automated microblasting

Advanced Lathe integrates micro-abrasive blasting technology with an advanced machining platform. This automated system delivers the accuracy, reliability and throughput to meet the challenges of today’s manufacturing environment.

Built for Abrasive Environments

The characteristics that make an abrasive a suitable choice for MicroBlasting make the protection of automation challenging. Unlike the large, blocky abrasives that are used in traditional sandblast cabinets our media is almost as hard as diamond and as fine as moon dust. Through our engineering expertise we are able to design and manufacture a system tough enough to withstand these harsh environments in a production environment.

Key features

-

EASY OPERATION

Select a program, load your parts, and you’re ready to start blasting. Quickly change between different types of parts. The refined user interface includes a bright, easy-to-read touch screen display.

-

MODULAR DESIGN

With up to four axes of motion, Advanced Lathe is capable of handling complex part geometries–and performing multiple operations during the same blast routine.

-

WORKS WITH ANY BLASTER

Advanced Lathe has been engineered to operate with either the AccuFlo or PowerFlo families of Comco blasters. The AccuFlo model is most commonly used for single nozzle applications. Multiple AccuFlo units or the PowerFlo are recommended for applications requiring multiple nozzles.

AUTOFILL

AutoFill replenishes the abrasive in your tank automatically so you never have to stop working to refill. AutoFill is an add-on module for the Tall-Tank model AccuFlo.

EXTERNAL INPUT SOURCES

Information and commands can be communicated to the Advanced Lathe from external sources. This can be a bar code reader, a scale, or another piece of automation like a robot.

INTERNAL TOOLING

While not really an accessory the Advanced Lathe can be configured with a multitude of modules to meet the application requirement. We have currently built a system with a traveling tailstock to accommodate parts of varying length, a turntable to rotate parts under the blast head, a serializing blast head for marking cylindrical parts, multiple spindles (1, 2, or 4), and the engineering OD blast head for development work on new applications.

Programming:

# of programs per system

Unlimited

# of subroutines per program

Unlimited

# of lines per program

1000 lines x 80 characters when translated for motion control card

Part Tooling:

Unique identifiers (max)

128

Outside diameter

.05 – 6.00 in

(1.3 – 152 mm)

Inside diameter

.02 – 5.50 in

(5.0 – 140 mm)

Blast Heads:

Unique identifiers

15

Nozzle diameter

.018 – .125 in

(.46 – 3.2 mm)

Nozzle quantity

1-8

Spindle:

Travel

± Infinite rotations

Speed (max)

± 750 RPM

Acceleration (max)

± 30.000 RPM/s

Positional resolution

(programmable/physical)

.02° / <.50°

Positional accuracy

<.5°

Positional repeatability

<.5°

X-Axis:

Travel

10.5 in (267 mm)

Speed (max)

±6.0 in/s (152 mm/s)

Acceleration (max)

±100 in/s/s

(2540 mm/s/s)

Positional resolution

(programmable/physical)

.000008 in / <.002 in

(.00020 mm / <.051mm)

Positional accuracy

<.005 in ( <.127 mm)

Positional repeatability

<.002 in (<.051 mm)

Y-Axis (optional):

Travel

5 in (127 mm)

Speed (max)

±3.0 in/s (76 mm/s)

Acceleration (max)

±100 in/s/s

(2540 mm/s/s)

Positional resolution

(programmable/physical)

.000002 in / <.002 in

(.00051 mm / <.051mm)

Positional accuracy

<.005 in ( <.127 mm)

Positional repeatability

<.002 in (<.051 mm)

Z-Axis:

Travel

4 in (102 mm)

Speed (max)

±3 in/s (76 mm/s)

Acceleration (max)

±100 in/s/s

(2540 mm/s/s)

Positional resolution

(programmable/physical)

.000005 in / <.002 in

(.00013 mm / <.051mm)

Positional accuracy

<.002 in ( <.51 mm)

Positional repeatability

<.002 in ( <.51 mm)

Model:

LA3250 Advanced Lathe

Compressed air for LA3250:

100 to 125 PSIG (6.9 to 8.6 Bars),

3 SCFM (85SLM) of clean, dry shop air

*Compressed air for PowerFlo® model PF2400:

90 to 140 PSIG (6.2 to 9.7 Bars), 10-12 SCFM typical (283-340 SLM) Dried to -25°F dew point and oil content filtered to <10ppm

Dust Collection:

1,000 SCFM (28,000 SLM)

Electrical:

115V 60Hz, 400 Watts

230V 50Hz, 400 Watts

Dimensions:

48” wide x 30” deep x 68” tall 122 cm wide x 76 cm deep x 173 cm tall

Try our process

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a demo