Maintenance & Troubleshooting

FAQ MicroBlaster

Comco’s MicroBlasters are built to last, and we do our best to make sure that every blaster is ready to go after installation. However, each abrasive environment and application are unique. So, from time to time, an issue may arise.

A list of Frequently Asked Questions and potential solutions are loosely organized below. Click on the question to see its answer in the drop-down box. Please use this page as a guide to perform simple maintenance and to better understand your blasting system.

If you need further assistance, please call us at 1-818-841-5500 or contact our Technical Support Team.

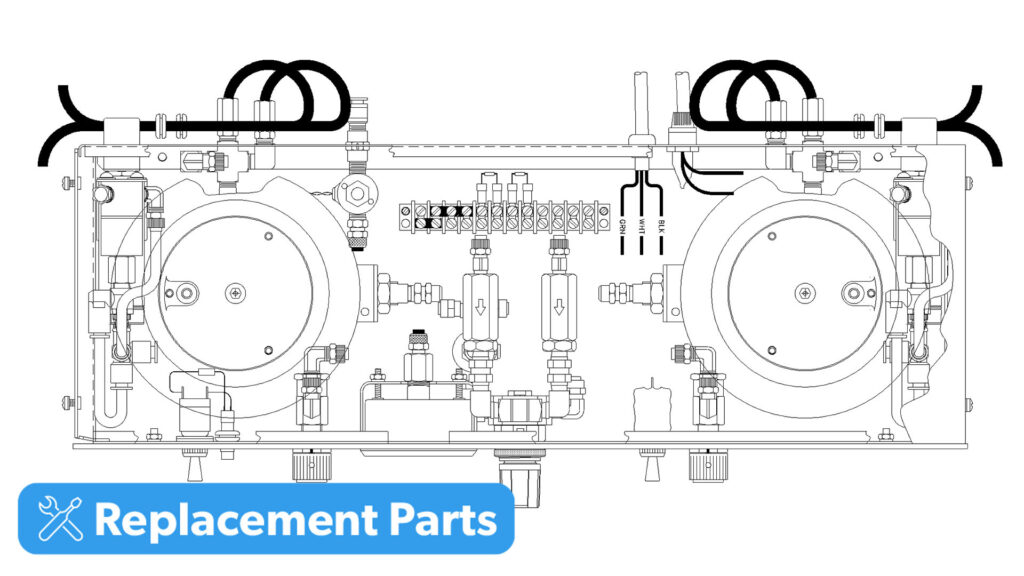

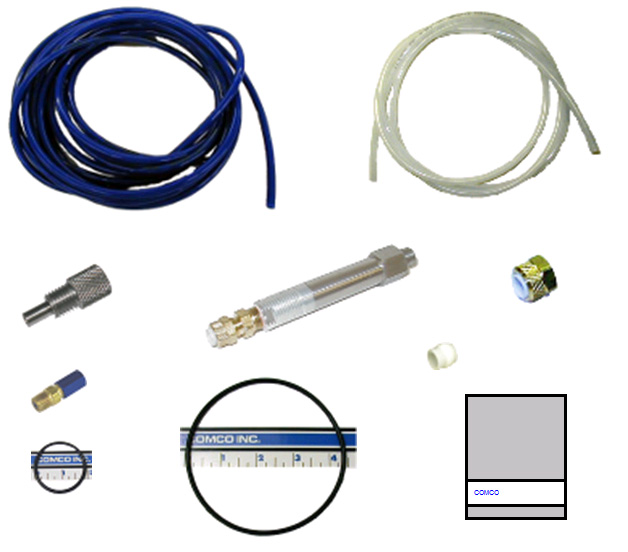

What’s in the MicroBlaster maintenance kits?

MB1440 MICROBLASTER TUNE-UP KIT INCLUDES:

- 5 ST4020 1/4″ ferrules

- 2 MB1455 hose connectors with Quicknut

- 2 ST4019 brass nuts with sleeve

- 25 feet of MB1233 1/4″ abrasive hose

- 3 feet ST4012 1/4″ nylon tube

- 1 MB1230-1 nozzle nose

- 1 MB1301-2 modulator housing assembly

- 1 ST5022 O-ring

- 1 ST5624 O-ring

- Instructions

Note: If you have an older tank cover assembly (MB1068), you also need to purchase the MB1450 MicroBlaster O-ring kit.

Note: Dual tank MicroBlasters require two tune-up kits.

THE MB1274-3 MICROBLASTER REPLACEMENT PARTS KIT INCLUDES:

- 1 MB1230-1 nozzle nose

- 1 MB1455 hose connector with Quicknut

- 2 ST4019 brass nuts with sleeve

- 25 feet of MB1233 1/4″ abrasive hose

THE MB1450 MICROBLASTER® TANK COVER O-RING KIT INCLUDES:

- 2 ST5022 O-rings

- 2 ST5023 O-rings

- ¼ oz. tube of adhesive

- Thread gauge

- O-ring replacement instructions

Note: For use on older MicroBlaster models equipped with the MB1068 tank cover assembly.

Why isn’t abrasive flowing out of the nozzle (but air is)?

Use the following chart to determine the problem:

| Items to Check | Solution |

|---|---|

| Is any abrasive flowing? |

|

| Is the tank orifice plugged? |

|

| Is the tank orifice too small for the powder? |

|

| Is moisture contaminating the abrasive? |

|

| Is the modulator functioning? |

|

| Are you using abrasive from a manufacturer other than Comco? |

|

Why are neither air nor abrasive exiting the nozzle?

Use the following chart to determine the problem:

| Items to Check | Solution |

|---|---|

| Is the electrical power ON? |

|

| Does the pressure gage indicate pressure in the system? |

|

| Is the inlet valve working properly? |

|

| Is the nozzle plugged? |

|

| Is the abrasive hose pinch valve (on the rear panel) opening? |

|

| Is there a problem with the abrasive line? |

|

| Is the tank pressurizing? |

|

| Is the check valve/ filter plugged with abrasive? |

|

| Is the modulator working properly? |

|

Why is the abrasive hose wearing out so quickly?

- Verify that the appropriate abrasive hose is in use. We recommend only using our brand of abrasive hose with our equipment. If unsure, call our Customer Service Specialists at 818-841-5500.

- Verify that the hose has not been pulled tight from the output fitting to the pinch valve.

- Inspect the hose for sharp bends. Any sharp bend creates a wear point.

- Not all wear is completely visible. Do not cut off short sections of the hose as those sections wear quickly. Replace the entire hose instead.

- Inspect the output fitting for wear. If worn, it can crush the abrasive hose, creating excessive wear. Replace the fitting if necessary.

- Inspect the pinch valve assembly. Any sharp edges on the plunger or pinch tube will cause hose to wear faster.

Why is there too much abrasive in my air stream?

- Make sure the tank has not been overfilled above the top of the vent tube. The stream will run rich with abrasive until the level drops below that point.

- Check the bypass tube that is pressed into the bottom of the tank. Has it developed a hole through which abrasive is being drawn? If so, then replace.

- Make sure that orifice is properly screwed in. If it is not, then it may allow air and abrasive to travel around the threads.

- Inspect the orifice for wear. If worn, the opening will grow too large. Replace the orifice if necessary.

- The orifice should be no larger than .005 its stamped size. Use a pin gauge to inspect.

- If changing out of the orifice, vacuum all abrasive in the bottom of the tank. Leftover abrasive will cause the orifice to cross-thread and not seal properly.

Why are the pinch cylinders unresponsive or moving slowly?

- Check for abrasive contamination. This happens when the check valves fail.

- Check the breather port on the side of the cylinder. Is it plugged and preventing air from passing through? If yes, then unscrew it, tap out the clog and restore.

- If neither of these options increase pinch valve speed, then contact our Technical Support Specialists at 818-841-5500 / techsupport@comcoinc.com.

Why won’t my machine pressurize properly?

Use the following chart to determine the problem:

| Items to check | Solution |

|---|---|

| Is the air supply to the unit suffiicient? |

|

| Are the pinch valves closing properly? |

|

| Is the O-ring in the tank cover worn? Is the tank cover worn? |

|

Also, view this video post on how to pressurize your system and achieve flow.

Why does my system have trouble maintaining consistent air pressure?

WARNING: The upper limit for air pressure is dictated by the house line pressure. There should be a 10psi buffer between blast pressure and line pressure. Turning the regulator knob clockwise beyond the line pressure will not increase blast pressure and potentially damage the regulator diaphragm.

Use the following chart to determine the problem:

| Items to Check | Solution |

|---|---|

| Does your regulator hold the proper pressure? |

|

| Does the regulator stay at the desired blast pressure when idle only to drop significantly once blasting starts? |

|

| Does the regulator drop less than 5 psi, but the air flow out of the nozzle is too weak? |

|

Also, view this video post on how to pressurize your system and achieve flow.

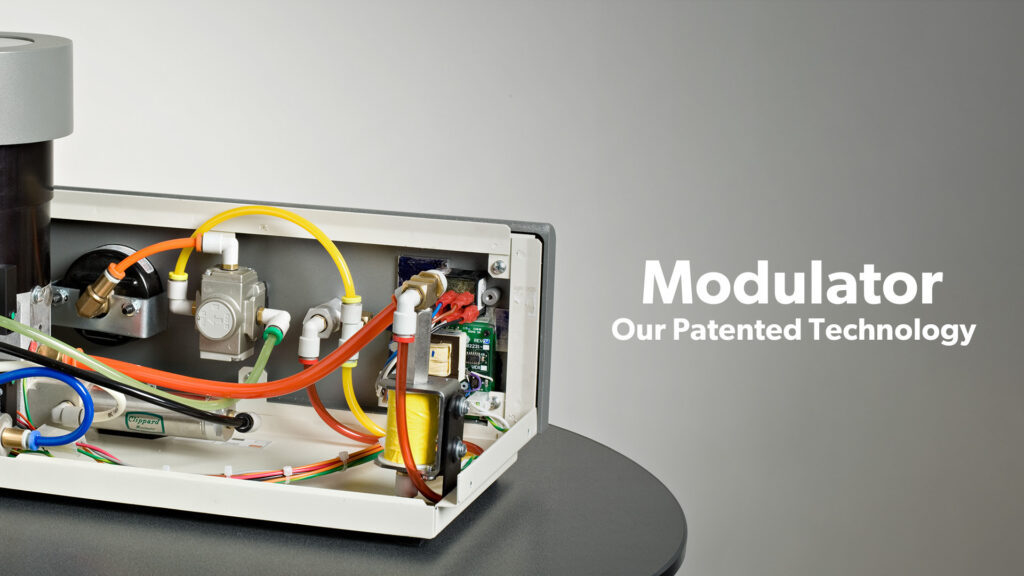

What happens when my modulator wears out?

Diminished media flow after the first 5-10 seconds of blasting is a good indicator that the modulator is wearing out. The modulator is a precision electromagnetic valve that operates 50-60 times per second. This creates a pulsed air stream, fluidizing abrasive and drawing it from the tank to the mixing chamber.

Learn more in our post Understanding Modulator Wear and Repair.

How does oil contamination affect my blaster? How do I know if oil is contaminating my Microblaster?

Oil contamination causes clumps and clogs of abrasive at the orifice in the abrasive tank and in the nozzle. These clogs disrupt air flow and worse, may cause check-valve failure. Oil contamination prevents the check-valve from sealing properly, allowing abrasive to pass back through the system. The aggressive nature of abrasive quickly erodes the O-rings and seals on these components, resulting in costly repairs.

If you suspect that your MicroBlaster is contaminated with oil, there are a few signs you can look for to confirm this. New air lines that run clean air through the MicroBlaster are a milky white color. Exposure to oil causes these lines to turn a shade of orange or yellow.

To check for oil contamination:

- Unscrew the black plastic bonnet inside the regulator to check for oil pools: oil tends to pool in the regulator assembly of the MicroBlaster.

- Open the assembly to expose the filter element. Large clumps of abrasive stuck to the filter element indicate oil contamination.

Please read our post on Oil Contamination.

What is the difference between the old style and the new style tank covers, and how do I replace my tank cover?

The new style tank cover introduced in 2003 are designed for longer life and easier maintenance. If your tank has a label on the top like the one pictured here, then your MicroBlaster has the new style square Acme threads. Please order the Replacement Tank Cover Assembly, part number MB1568.

If your blaster does not have a label on top like the one pictured, then your MicroBlaster will not fit the new style tank cover unless you replace the tank as well as the cover. Tank replacement must be done at the factory. Please contact Technical Support at 818-841-5500 or techsupport@comcoinc.com for an RMA number before sending in your machine. Learn the advantages of the new tank cover design.

What range of nozzles are available?

Our nozzles come in an array of shapes and sizes for a wide range of applications. The straight, round style nozzle with openings ranging from 0.015″ to 0.060″ meets most application requirements. Rectangular nozzles are available for applications that require a wide sweep or fan of abrasive.

Comco’s offers long-lasting Hi/Performance nozzles in addition to standard nozzles. Hi/Performance nozzles deliver an accelerated abrasive flow with a tighter focus, resulting in less over spray. The lifespan of these nozzles is 3-5x longer than most standard nozzles.

Why is my nozzle wearing out so quickly?

Use the following chart to determine the problem:

| Items to Check | Solution |

|---|---|

| Is an O-ring in place? |

|

| Does the hose have a sharp bend? |

|

| Are you using rectangular nozzles? |

|

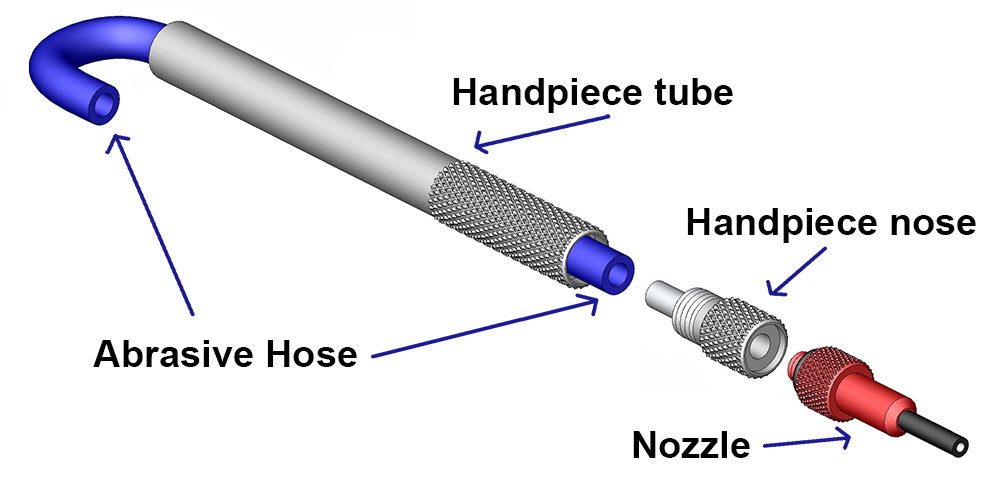

What parts comprise the handpiece assembly?