Process Optimization

How to Adjust the Abrasive Flow

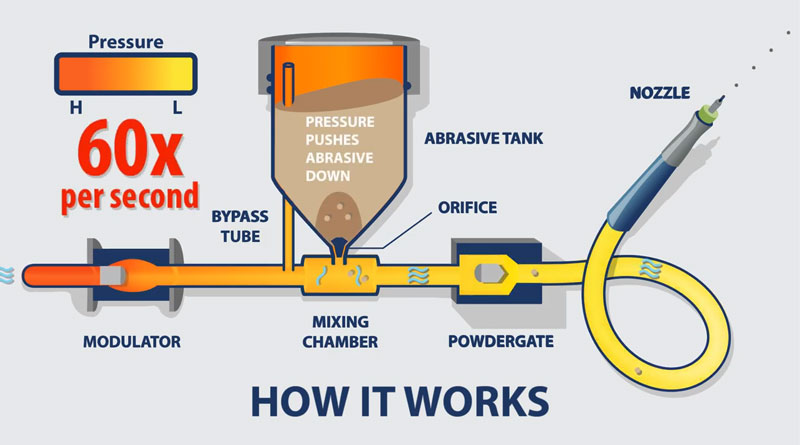

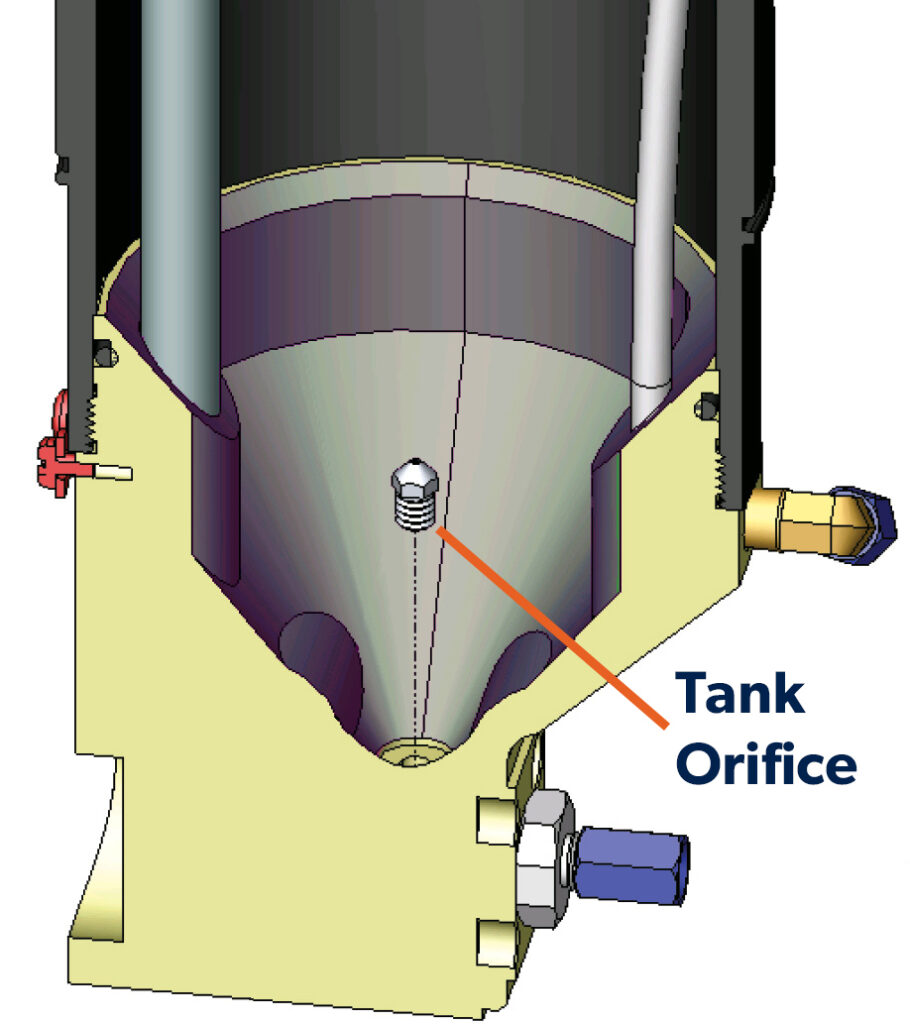

The tank orifice is an often overlooked component of our precision blasters, but plays a vital role in metering abrasive into the air stream. The orifice is assembled with a precision ceramic sleeve sized to control the amount of abrasive that passes through it. In all Comco blasters, pulses of air are created through our patented modulator. Each modulator cycle has a high pressure pulse that forces air up through the orifice to fluidize abrasive in the tank. The second half of the pulse creates a vacuum, drawing air from the tank through the orifice into the mixing chamber.

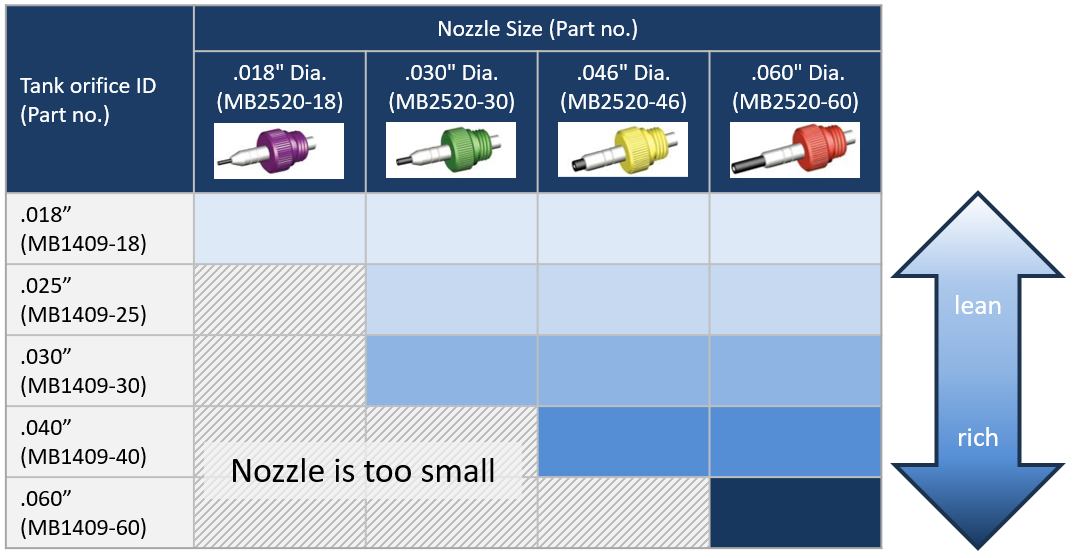

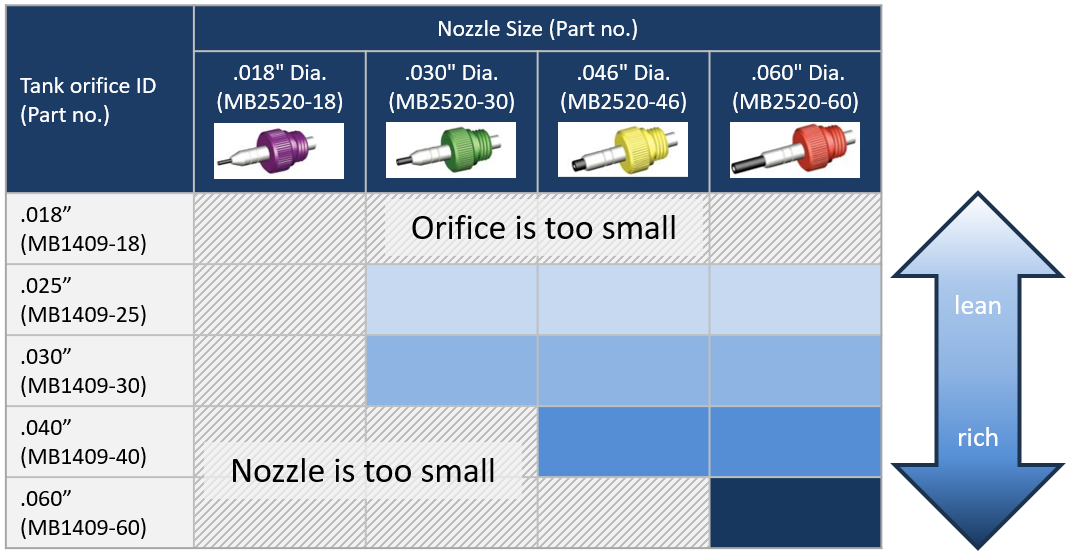

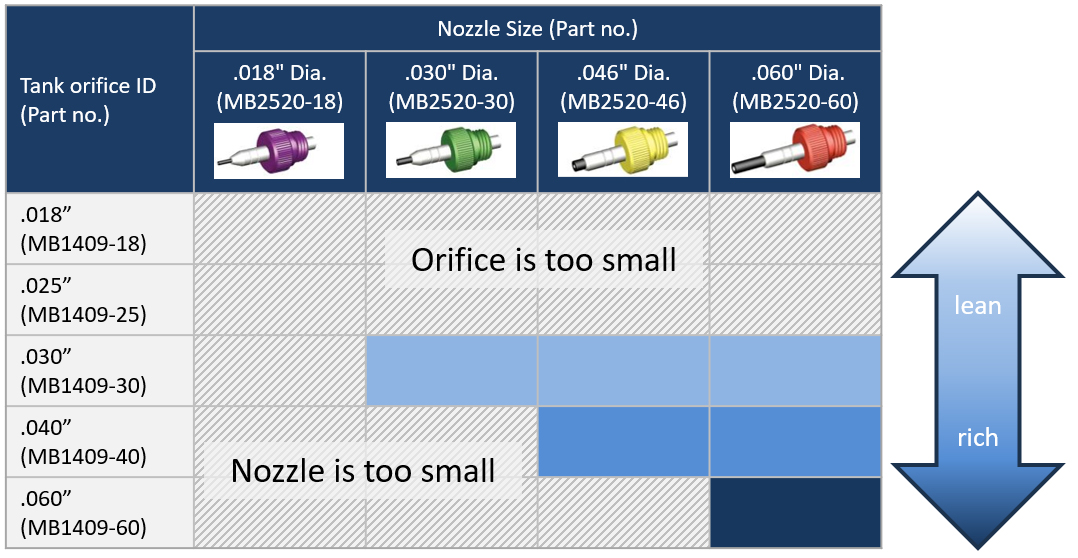

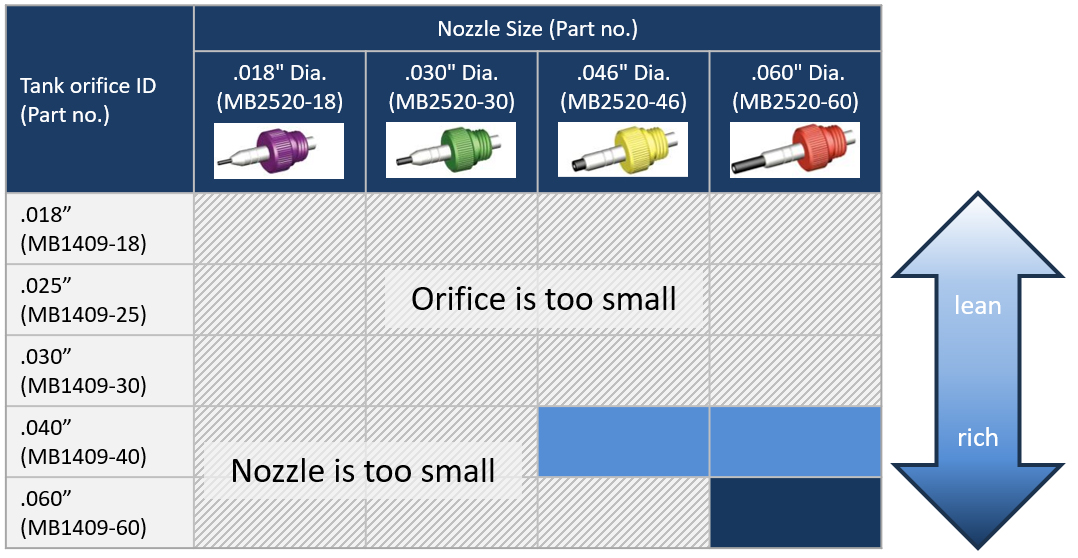

The size of the orifice is the key driver in determining the richness of the abrasive stream at the nozzle. The orifice is available in multiple sizes from 0.018” to 0.060”. Having the proper orifice in your MicroBlaster is the key to optimizing the speed and efficiency of the process.

Why Use a Richer Flow?

One of the primary reasons for increasing the richness of the abrasive flow is to speed up processing times. In general terms applications that benefit from a larger nozzle will also benefit from a larger orifice. Texturing or coating removal on large exposed surfaces can be completed more efficiently with a larger orifice.

WheN a Leaner Flow Is Preferred

Conversely, if the process involves getting down into small spaces or passageways a lean abrasive stream is better. If the abrasive is not able to get out of the way fast enough the abrasive jet is wasting energy. Additionally, the richer the abrasive stream the slower the particle velocity so applications that require high energy particles will benefit from a leaner abrasive stream.

HOW DO I SELECT THE RIGHT TANK ORIFICE?

There are three important factors in determining the right orifice size for your application. They are the size of the abrasive media, the size and number of nozzles, and the desired richness of the abrasive stream. The tables below will help you figure out exactly which one to use.

Select the abrasive size to see the related chart for determining the appropriate tank orifice size.

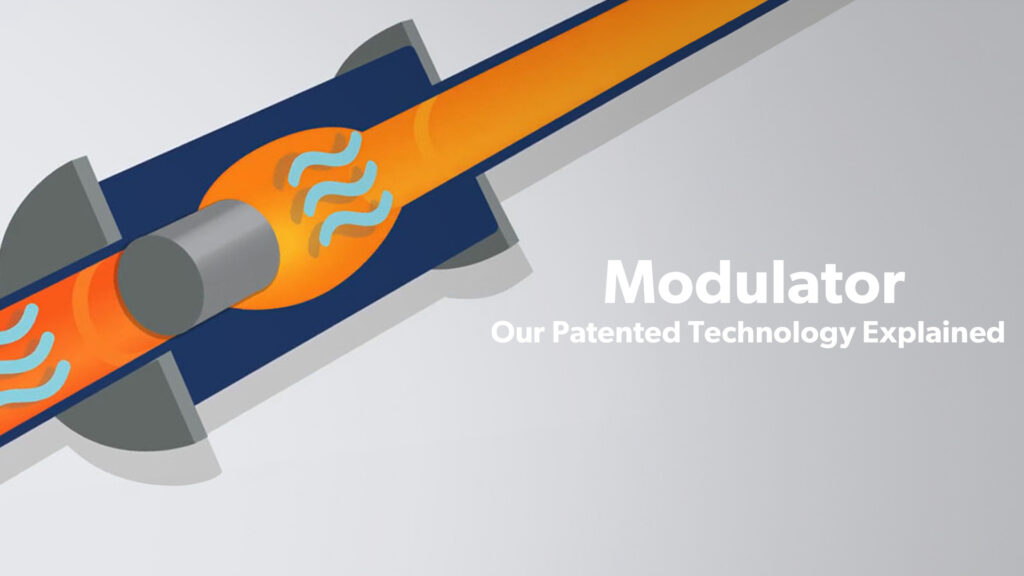

The Modulator

Working with fine abrasives as hard as diamond and as fine as moon dust is a challenge. Particles tend to stick together, so getting them to flow smoothly without surges is difficult. How do we feed really fine abrasive consistently?

The Comco Modulator—it’s the pulsing heart of our system that transforms the technology from a dirt sprayer into a precision tool.