MicroBlasting Technologies for Aerospace Applications

Our MicroBlasting Systems are used to texture, deburr, clean, etch, and cut a wide variety of materials—even the most delicate. We’ll work closely with you to land on custom solutions for your aerospace engineering and manufacturing needs.

What can be achieved with MicroBlasting?

Our MicroBlasting technologies and engineering expertise have helped our clients solve an array of challenges in the aerospace field from precision deburring of fuel splines, and gears, to etching precision grooves into the surface of a seal to create an air bearing in a hydrodynamic seal and turbine regeneration.

55+

Years

We have over 55 years of experience in perfecting MicroBlasting technologies and partnering with clients to help them solve their unique manufacturing challenges.

2.3k

Assets sold across 600+ customers in the aerospace industry

We’ve worked with 600+ customers in the aerospace industry, and faced many of the engineering challenges they deal with on a daily basis.

2–200

Microns

Our equipment can remove a wide range of coating thicknesses from 2 to 200 microns, and +/- 1/2 micron machining depth tolerance.

Surface Alteration & Material Removal on Aerospace Parts

Texturing load cells for bond adhesion

Multi-axis load cells measure force and torque in six dimensions

Surface Texturing from the Blog

Need to Improve Bond Strength?

Are you solely specifying Ra to determine bond strength? Do you see variation in pull or peel tests? We find that specifying Ra alone rarely provides a comprehensive understanding of a surface’s bonding potential. To improve bond strength, incorporate developed surface ratio (Sdr) and full coverage into your specification. Here’s why…

Read More

Need a consistent and repeatable surface finish?

What do you include in your surface finish specification? Abrasive type and size? Blast pressure? Anything else? Like the majority of first-time MicroBlasting users, you might stop at those points. Unfortunately, this limited outline opens the door to inconsistent surface finish results.

Read More

How to calculate stempover and get a uniform surface finish

“Where did these stripes come from?” This is a question we hear in automated texturing and etching applications. Most customers want to avoid creating a barber-pole or stripe pattern on their part surface.

Read MoreReconditioningTurbine Blades

Removing metalization on ceramic components

Coating Removal from the Blog

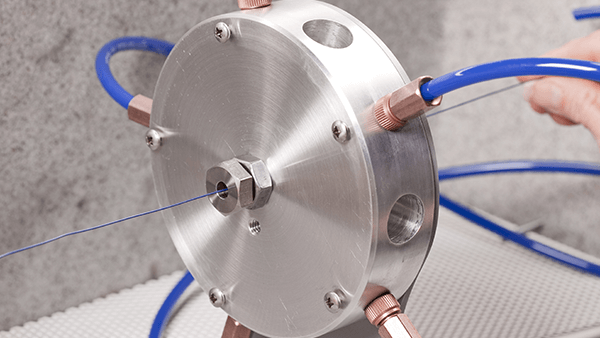

Wire Stripping? Get uniform removal + sharp delineation with the ring nozzle

Our SP1906 Nozzle Array, or the Ring Nozzle, mounts to the floor or the side of any Comco WorkStation and turns coating removal and texturing into a quick and precise one-person task.

Read More

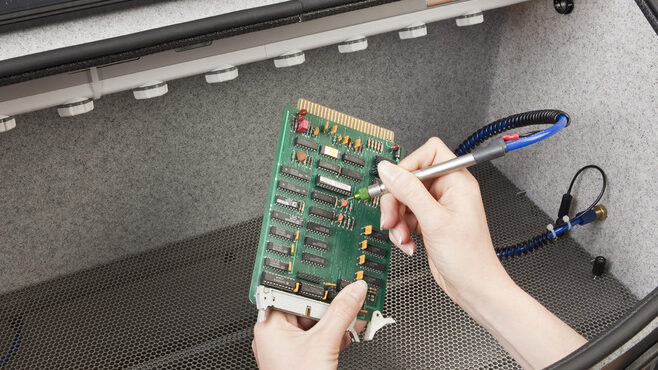

Static Sensitive Application?

MicroBlasting provides a gentle, precise and controllable approach to selectively remove parylene, epoxy, polyurethane, silicone, acrylic and more without danger.

Read More

Turbine blade regeneration using MicroBlasting

Whether you’re refurbishing landbased gas or jet-engine turbines, MircoBlasting is the ideal method of cleaning turbine blades. When turbines are split in two for maintenance, hot path components and combustion components are pulled out for repair.

Read moreDeburring Precision Valves and Manifolds

Deburring Black PEEK

Precision Deburring from the Blog

6 quick deburring case studies

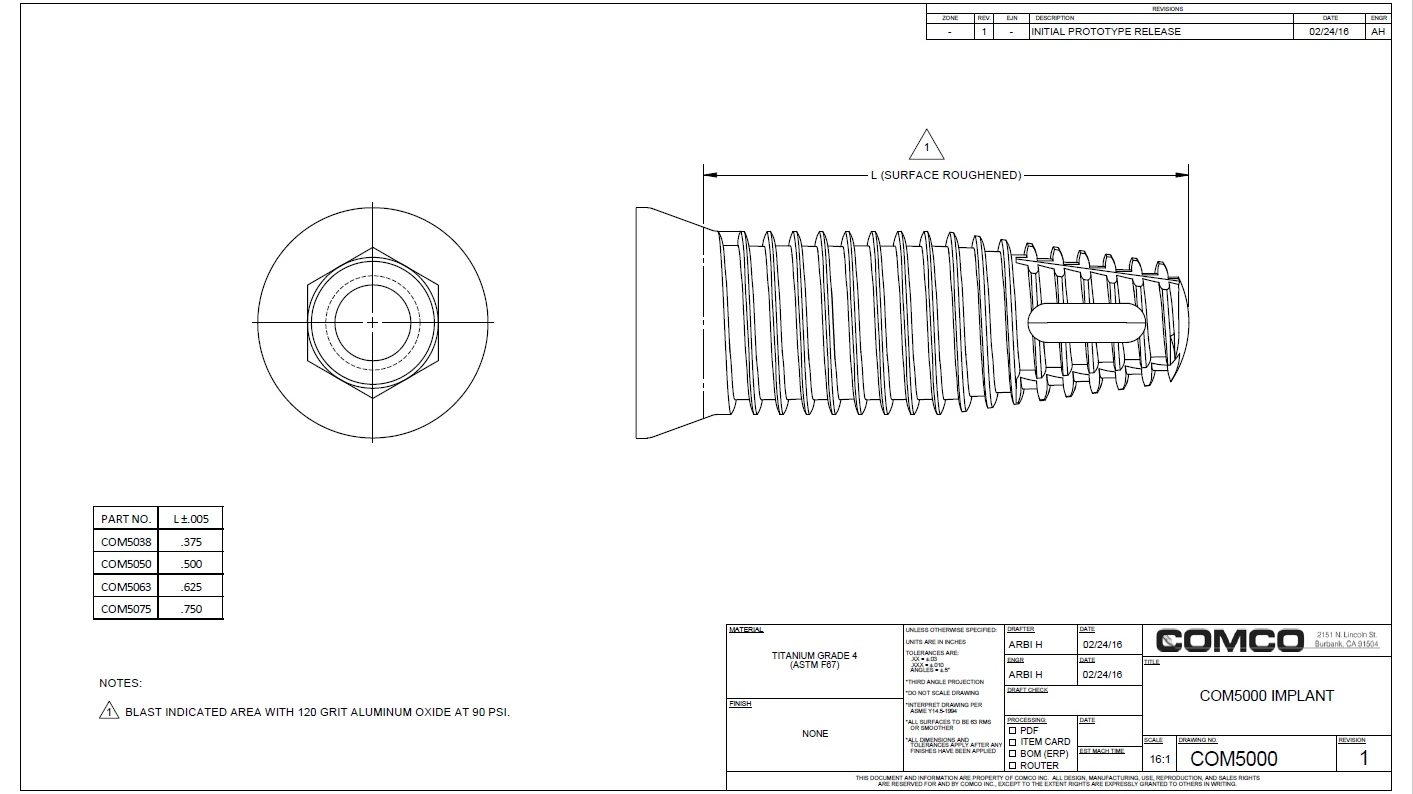

Learn what abrasive, nozzle and blast pressure are used to precisely remove burrs and refine surfaces on these small, intricate parts. Includes: metal gears, PEEK spinal implants, electronic packages, stainless steel valve components, aluminum fixtures and titanium components.

Read More

Five Factors that Lead to Successful Deburring

Knowing the 5 factors that lead to successful deburring will help you and your team improve your approach, work more efficiently, and get the most out of your blasting system.

Read More

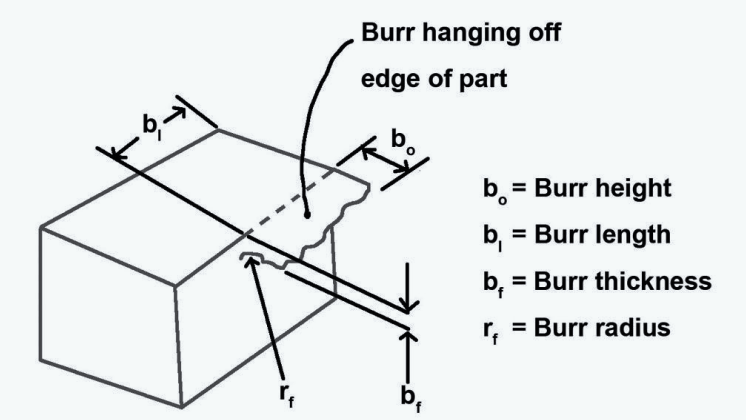

The Missing Measurements of Deburring

Are burrs suddenly popping up again in your machining process?rnAre new burrs appearing in a different location on your part?rnAre you having a hard time selecting a deburring method?rnHas your once-successful deburring method started to fail? Chances are, you’re missing a measurement.

Read MoreMachining grooves into hydrodynamic seals

Thermocouples

Abrasive Jet Machining from the Blog

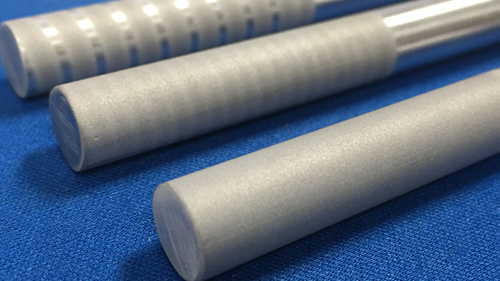

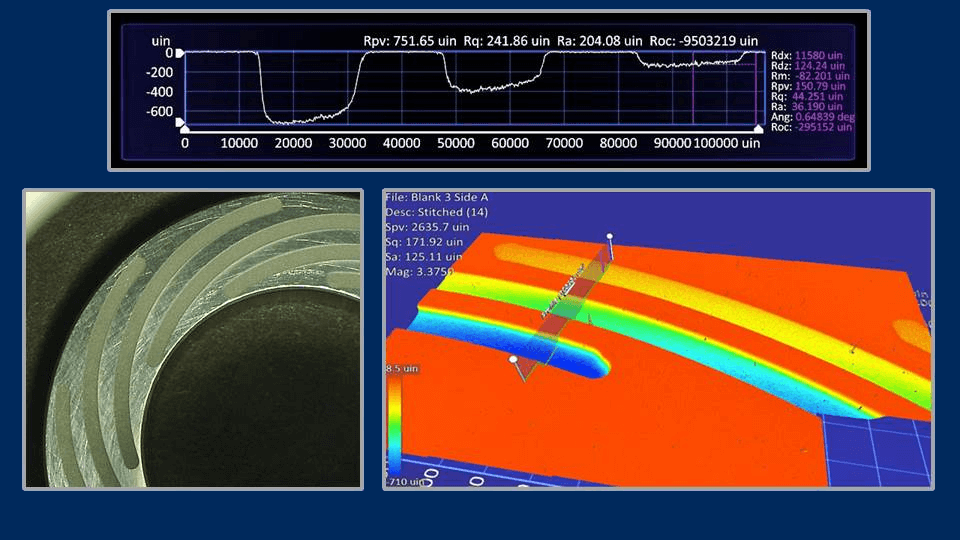

How to create features of a specific depth

A single pass of the focused abrasive stream from a MicroBlaster can uniformly remove 5 µin (0.127 microns) or less of material depending on the substrate, abrasive, and blast parameters. Given this level of precise and controllable erosion, you simply need to know how to fine-tune the process to suit your application.

Read More

5 Variables for Abrasive Jet Machining

Using MicroBlasting to cut or etch a part (a process also known as controlled erosion) is a great method to machine many precision parts, from drilling holes in ceramic substrates to cutting slots in fragile silicon and glass wafers. MicroBlasting is “shockless,” generating neither heat nor vibration, meaning microcracks are less likely to form and damage part integrity.

Read More

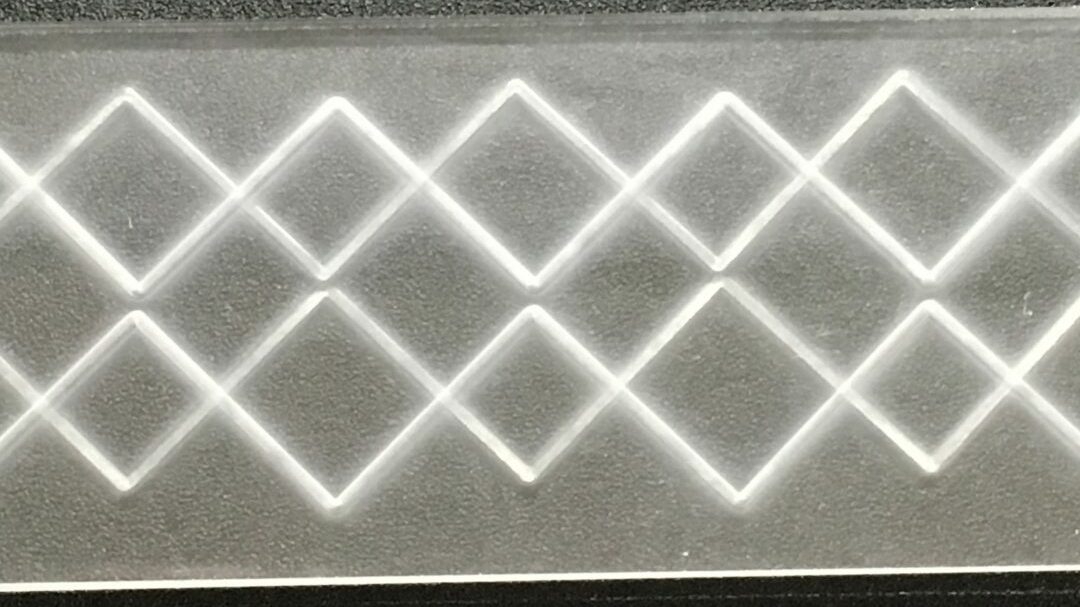

Etching channels to create an air bearing or hydrodynamic seal

Bearings inside turbine engines operate at high speeds in a harsh environment where traditional rolling contact or static bearings would not survive. To improve reliability and fuel efficiency specifically on jet engines, shallow channels are incorporated into the design in which air flows rather than traditional lubricants. The technical challenge is how to create these channels.

Read more

Your Partner for Industrial Engineering Solutions.

We’ll work closely with you by applying our engineering skills to your problem, providing the process with our technologies, and sharing our accumulated expertise to develop solutions that are efficient and cost effective.

-

Applied Engineering with a Deep Understanding of Aerospace Parts

Engineering is at the core of Comco. Our engineers have a background in the medical, aerospace, and semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

-

Providing the process at no additional cost to you

Let us prove how a custom MicroBlasting process would work for you while sharing our engineering expertise up front, without charge.

-

Sharing our skills & knowledge throughout our partnership

We’ll share our engineering skills and knowledge at every step of our partnership. Advanced technical support continues beyond your initial purchase of our MicroBlasting systems, and we also offer assistance with new applications as they arise.

TRY OUR PROCESS

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a Demo

A Complete MicroBlasting Solution

Comfortable

Ergonomic design reduces operator fatigue

Versatile

Flows a wide range of media

Consistent

Unique patented modulated abrasive feed

User Friendly

Easy to set-up and easy to maintain

Mobile

Casters allow for adaptive cell environments

Clean & Quiet

HEPA filtration and customized fan box improves operation

Cost-effective

Our best for a turnkey solution

Customizable

Offers a range of workholding and blast head options

Scalable

Designed to grow from manual to fully automatic

User Friendly

Intuitive user interface for programming and operation

Turnkey

Delivered production ready

Peace of mind

Fully documented and supported

Consistent

Unique patented modulated abrasive feed

Robust

Stable in full production