What is MicroBlasting?

MicroBlasting, or sandblasting on a micro-scale, is one of the most versatile surface alteration and material removal methods available. By simply adjusting the blast pressure, abrasive or nozzle, a Comco blaster easily turns from a tool that cuts vias in silicon wafers into a tool that deburrs the heal of stainless steel needles or a tool that textures bone screws.

Unfamiliar with MicroBlasting?

Are small imperfections getting in the way of your big idea? MicroBlasting is specifically designed to benefit small, intricate, and high-value parts. Unlike traditional sandblasting, MicroBlasting uses high velocity, micron-sized abrasives that can target and remove microns of material. The result is a reliable and repeatable method for deburring, texturing, cleaning, stripping, etching or milling part surfaces.

Solutions for Every Application

Surface Texturing

Engineering surface finishes for integration.

Dental Implants

Texturing a dental implant accelerates osseo-integration.

Ceramic Wafers

Texture the surface of a silicon wafer to improve light absorption and decrease reflection.

Multi-axis Load Cells

MicroBlasting is used to cut through the black anodize and texture the surface to improve the bond with flex circuitry.

Coating Removal

Remove coatings without damaging the underlying part.

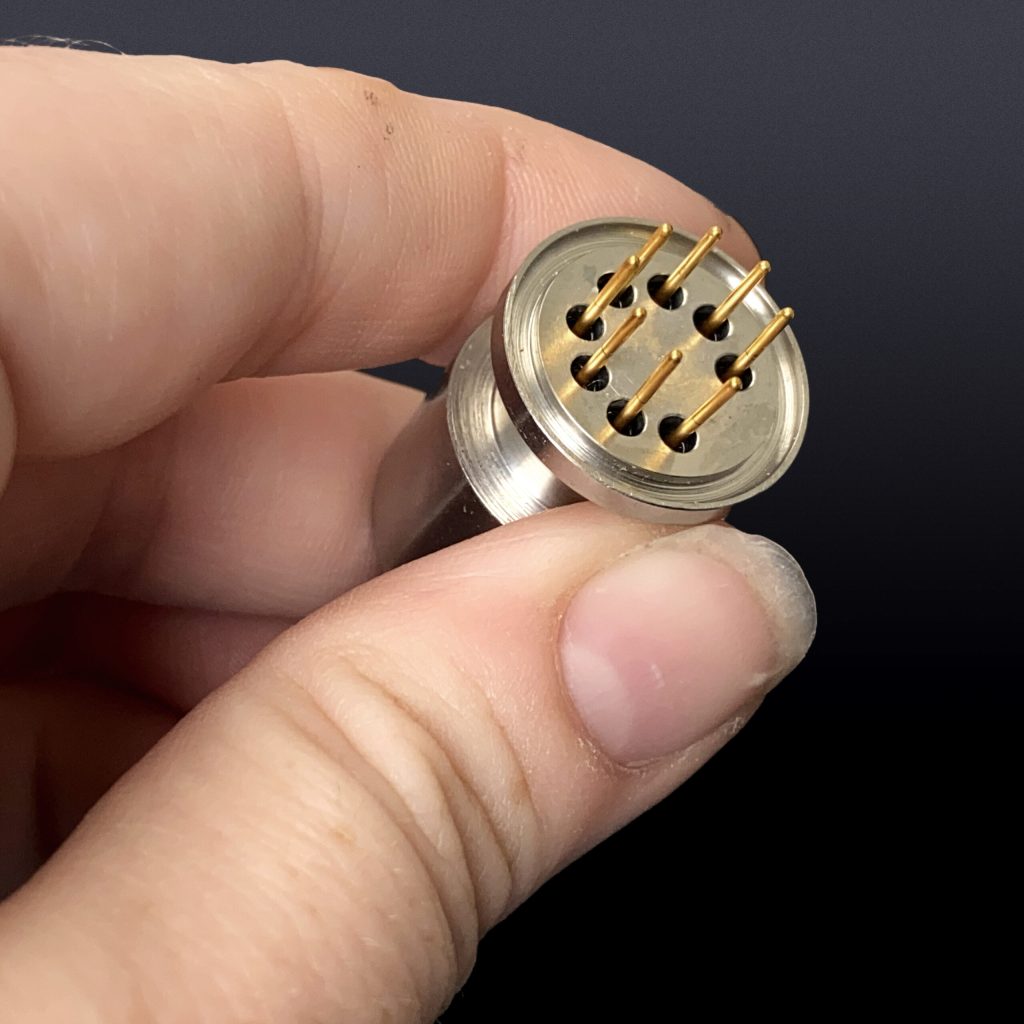

Pacemaker Headers

Remove excess encapsulation that seeps out from the header during installation.

Reconditioning Turbine Blades

Refurbish either land-based gas or jet-engine turbines by removing the protective oxide layer.

Metalization on ceramic components

Remove metalization on ceramic components to improve electrical isolation.

Precision Deburring

Remove fine feather burrs without dimensional changes.

Polymers

Certain softer abrasives, like Sodium Bicarbonate, remove burrs quickly without damaging the underlying surface.

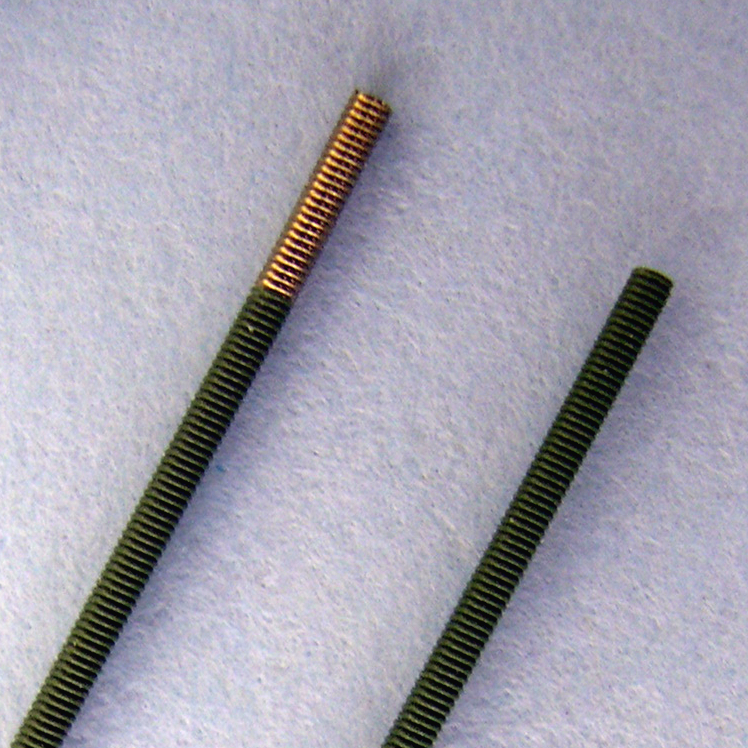

Bone Screws

Remove burrs while maintaining a sharp cutting edge. Can also create a compressive layer on the surface of the threads, which helps to improve the fatigue life.

Metals

Titanium hardens as it heats up, making it tough to machine. MicroBlasting with glass bead gently removes burrs without changing part geometry.

Abrasive Jet Machining

Drill holes, cut slots without generating heat nor vibration.

Lens Engraving

Etch serial numbers into lenses for ring laser gyros without creating micro-cracks. rnrn

Hydrodynamic seals

Etch shallow channels into the groves or channels of the surface of a seal to crate an air bearing.

Thermocouples

Remove MgO to expose contacts for bonding on heat-sensing harnesses.

MicroBlasting is effective on a wide range of materials.

Browse Materials

Materials We’ve Worked With

MicroBlasting is used on a variety of materials and compositions, thanks in part to the wide range of abrasive media available. We often work with the following materials used by the medical, aerospace, automotive, semiconductor and power systems industries. Can’t find what you’re looking for? Contact us and we’ll let you know how your material(s) can be used with our MicroBlasting technologies.

Aluminum

Bronze

Copper

Ceramic

Glass

Graphite

Inconel

Kovar

Nitinol

Polypropylene

PEEK

PTFE

Silicon

Stainless Steel

Titanium

Brass

A Complete MicroBlasting Solution

Comfortable

Ergonomic design reduces operator fatigue

Versatile

Flows a wide range of media

Consistent

Unique patented modulated abrasive feed

User Friendly

Easy to set-up and easy to maintain

Mobile

Casters allow for adaptive cell environments

Clean & Quiet

HEPA filtration and customized fan box improves operation

Cost-effective

Our best for a turnkey solution

Customizable

Offers a range of workholding and blast head options

Scalable

Designed to grow from manual to fully automatic

User Friendly

Intuitive user interface for programming and operation

Turnkey

Delivered production ready

Peace of mind

Fully documented and supported

Consistent

Unique patented modulated abrasive feed

Robust

Stable in full production

Your Partner for Industrial Engineering Solutions.

We’ll work closely with you by applying our engineering skills to your problem, providing the process with our technologies, and sharing our accumulated expertise to develop solutions that are efficient and cost effective.

-

Applied Engineering with a Deep Understanding of Manufacturing Processes

Engineering is at the core of Comco. Our engineers have a background in the medical, aerospace, and semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

-

Providing the process at no additional cost to you

Let us prove how a custom MicroBlasting process would work for you while sharing our engineering expertise up front, without charge.

-

Sharing our skills & knowledge throughout our partnership

We’ll share our engineering skills and knowledge at every step of our partnership. Advanced technical support continues beyond your initial purchase of our MicroBlasting systems, and we also offer assistance with new applications as they arise.