Maintenance & Troubleshooting

Keeping your Air Supply Dry

If you’ve ever been frustrated by a full, but non functioning salt shaker, discovered a suspect mass of whey in a tub of protein powder, or had to break up a chunk of powdered detergent, you know that fine powders and moisture are not a great combination.

The abrasives used in MicroBlasting range in size from 10-150 microns (a human hair is huge in comparison at 50 microns). Some materials are more sensitive to moisture than others, but every material becomes more sensitive as it gets smaller. The ratio of surface area to volume increases as particle size decreases. This creates more opportunity for water molecules to bond the abrasive particles together.

The greatest potential for moisture contamination comes from your air supply. Let’s look at how to prevent this.

Only blast with Dry Air

There are 3 locations where the air can become contaminated. The first is the drain valve at the bottom of the main reservoir, which takes out water that condenses during the compression process. Typically, a refrigerant dryer is connected to the compressor. This second step cools the air, and as cold air can hold less moisture than warm air, more water is drawn out through this phase. After passing through a refrigerant dryer the dew point is typically 40° F. MicroBlasting requires an additional step to achieve a dew point of -25° F. To achieve this level of dryness an active process is required, the two common methods are desiccant or membrane methods.

Desiccant Dryers

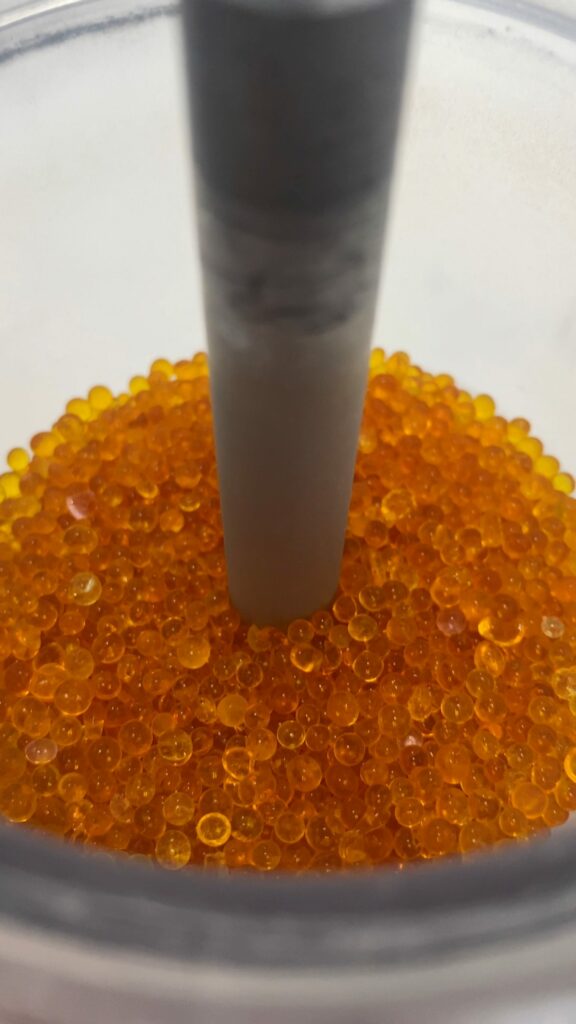

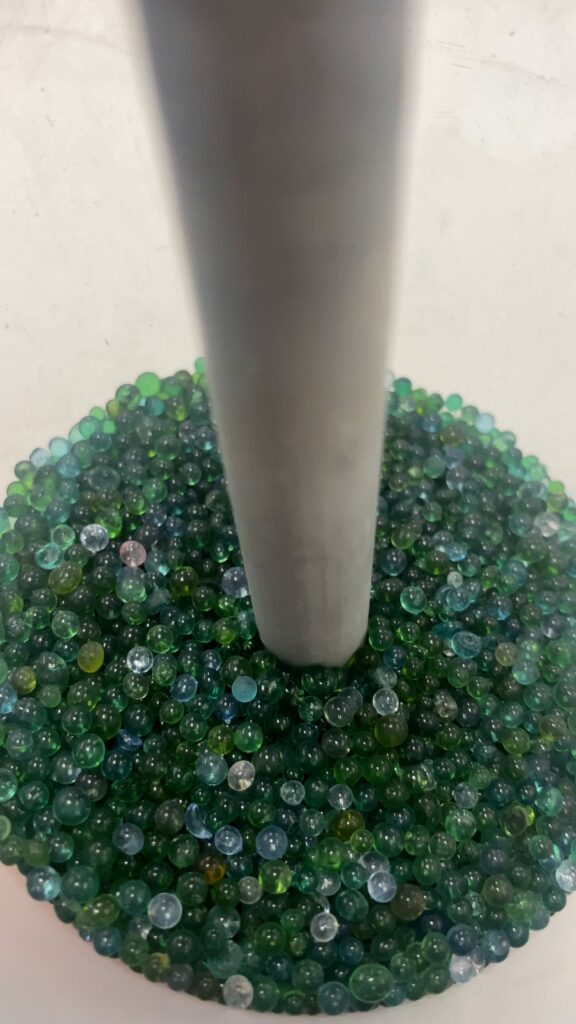

These use a super-absorbent bead that literally “pulls” moisture out of the compressed air as it passes through the dryer. When the beads are fresh they can achieve dew points as low as -35˚ F. The beads have a limit to the amount of moisture that they can absorb. Most manufacturers will use a bead that changes color when the bead becomes more saturated, typically orange to green. When the beads become green they will need to be either regenerated or replaced in steady use.

To regenerate the beads, the moisture must be driven off with heat. Each recharge causes the beads to lose some of their water holding capacity (like a cell phone battery that slowly looses it’s effectiveness over time).

Having trouble changing the desiccant charger on your ProCenter? Watch the video below to see how it’s done.

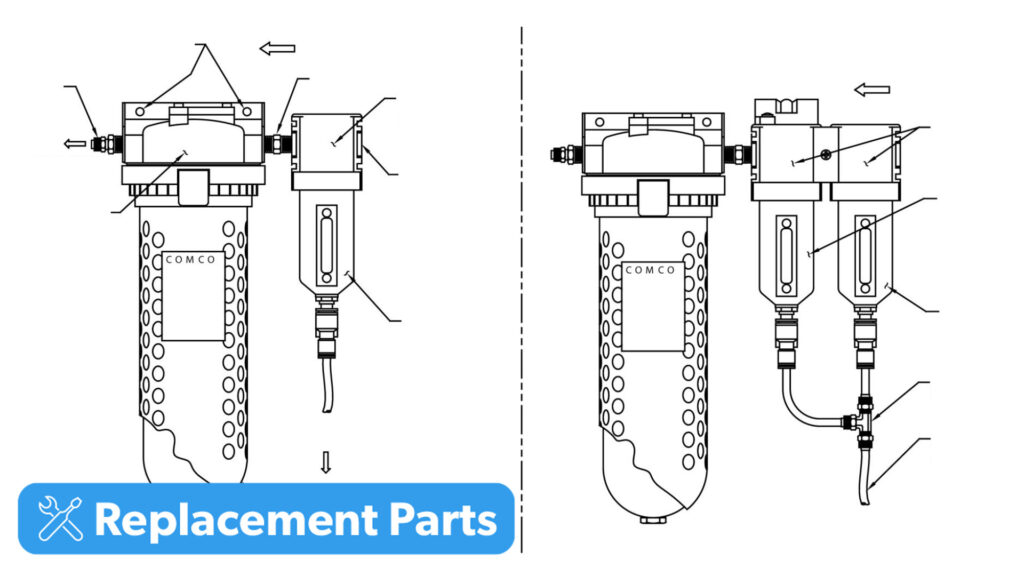

Membrane Dryers

This dryer uses a semipermeable hollow membrane, arranged in a series of tubes. Water vapor will diffuse through the tube wall (osmosis). Then an automatic air purge removes the moisture vapor from the tubes. By continuously removing water vapor from the system, maintenance associated with drying beads is removed. While the initial cost for a membrane dryer is usually higher than a desiccant, this is offset by the reduced need for maintenance over the life of the dryer.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.