Equipment Updates

Measuring Abrasive consumption

What is the Powder Trap?

The Powder Trap is used to check the rate of abrasive flow from a blaster. It can be used to validate abrasive flow for a blaster for tightly controlled processes, often when paired with an automated blasting system. It is also especially helpful in checking blasters for changes in flow due to component wear or other factors that can affect the flow.

Why this method works best

There are several ways to measure abrasive flow that we tried before arriving at the Powder Trap. Each had its own challenges:

- Weighing the blaster: the challenge lies in the finding an appropriate scale with both sufficient weight capacity and resolution for this job. A scale that can measure 30 pounds is not well equipped to monitor abrasive flow at 5 grams/minute.

- Capturing it in a small filter: the erosive nature of the process destroyed the small filters.

- Monitoring it in-line: though these measurements work well at identifying changes in abrasive flow, they tend to create more variation evaluating total mass consumed.

The most effective way to monitor abrasive consumption is to capture it after it leaves the nozzle. The ideal system needs to be light weight, effective, at filtration and reusable.

How to Validate your Blaster

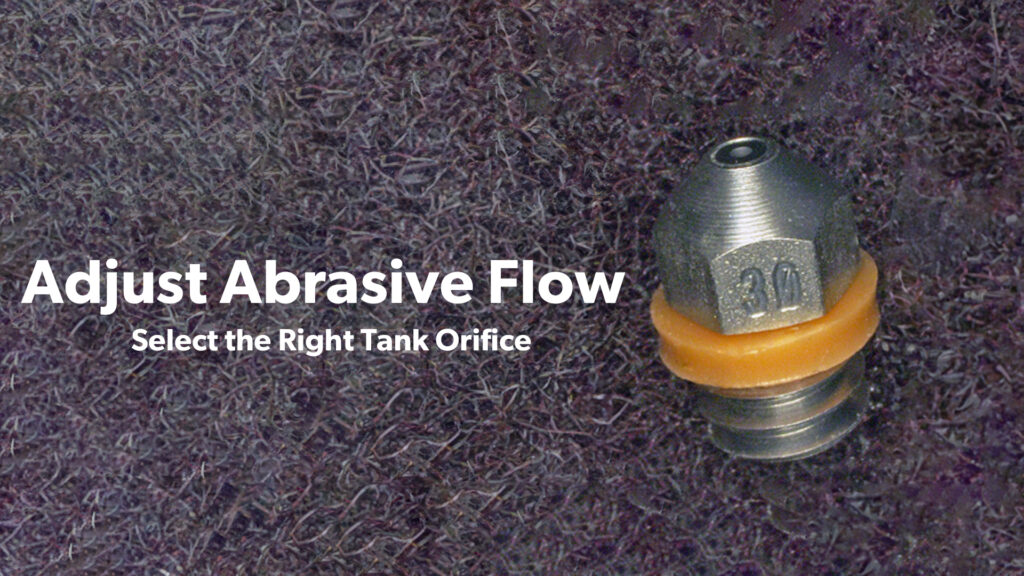

For best results we recommend configuring your blaster as you would use it in production. Use the same nozzle, orifice, and blast pressure. The duration of the trap test is dependent on system configuration, but typically we recommend a 2-3 minute test cycle. Items needed for validation in addition to the Powder Trap include:

- blaster

- stopwatch

- scale

For more information on the test procedure, refer to this tech sheet.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.