Equipment Updates

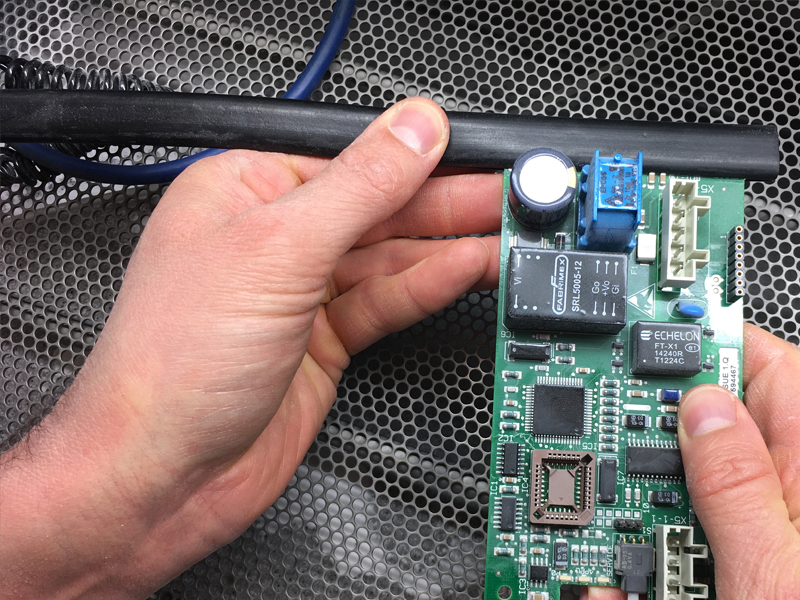

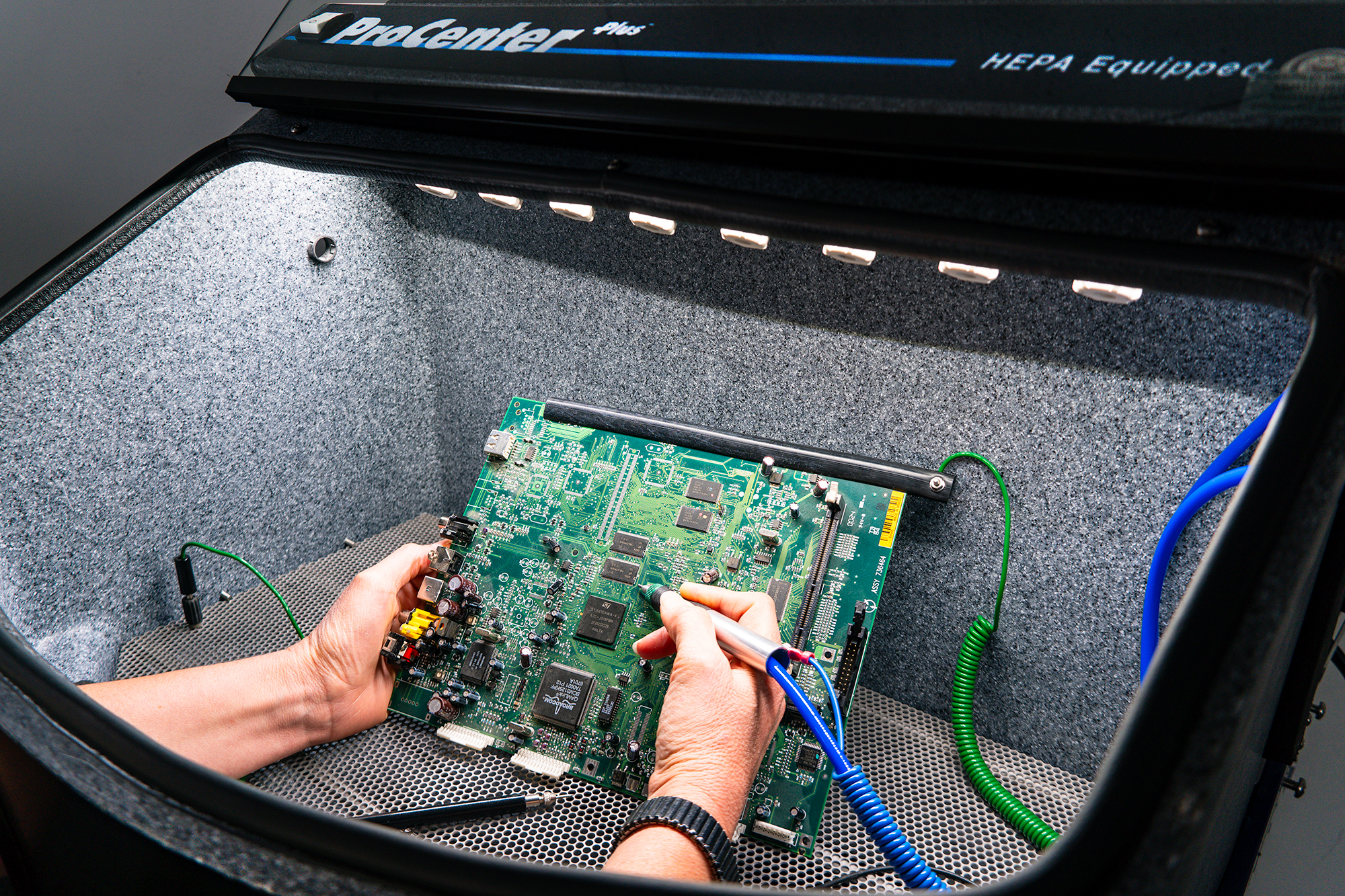

ProCenter Plus with ESD control

Any components that are sensitive to electrostatic should be processed in the ProCenter Plus with ESD Control. This unit delivers maximum protection against an ESD event.

What is the ProCenter Plus?

The ProCenter Plus is everything necessary to a MicroBlasting system except the blaster. It is a compact, chair-height workstation with an integrated dust collection system and an attached air dryer. It confines the blast area while a built‐in HEPA‐equipped dust collector extracts spent abrasive. It is easy to use and easy to maintain. The ProCenter Plus partners best with the AccuFlo® to form a complete manual MicroBlasting system.

The ProCenter Plus with ESD control (CTR202-E models) has additional features that collaboratively neutralize surface charges and reduce electrostatic build-up

Features that Neutralize ESD

Grounding Jacks

Provide convenient connection points for a wrist-stat, the edge grounding bar, and the needle probe.

Needle Proble

Pierces through the coating and grounds a target trace when the defect is known to be an open trace with no conductive path to ground.

Grounded Handpiece

Works with the conductive nozzle to provide a conduit for static, sending it straight to the grounding jacks instead of onto a PCB.

Conductive Nozzle

Limits the potential for a charge to travel to the board from the abrasive hose. A conductive nozzle also blocks a charge that could arc from the operator. Should be used with the grounded handpiece.

Ionizer Bar

Floods the entire work chamber with ionized air to neutralize static build-up. Built-in sensors monitor the effectiveness of the ion flow and indicator lights alert the operator to any changes in operation.

Grounding Jacks

Provide convenient connection points for a wrist-stat, the edge grounding bar, and the needle probe.

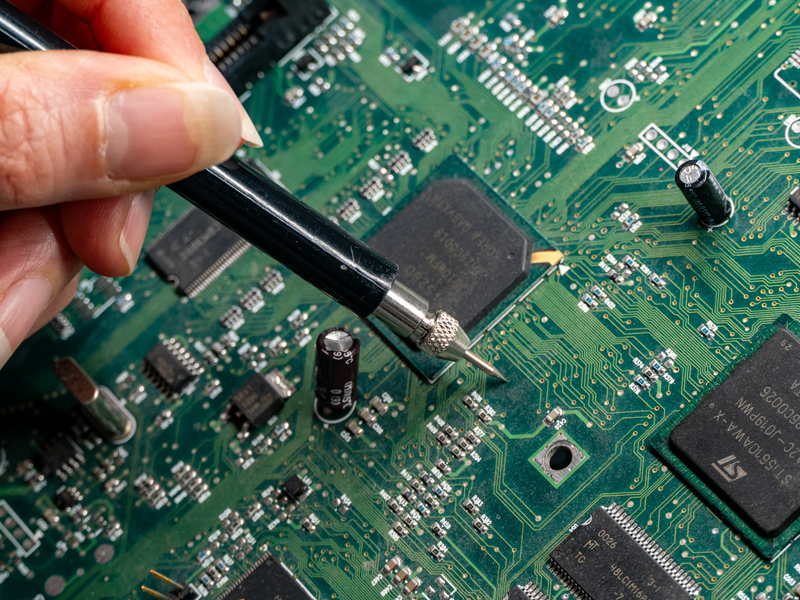

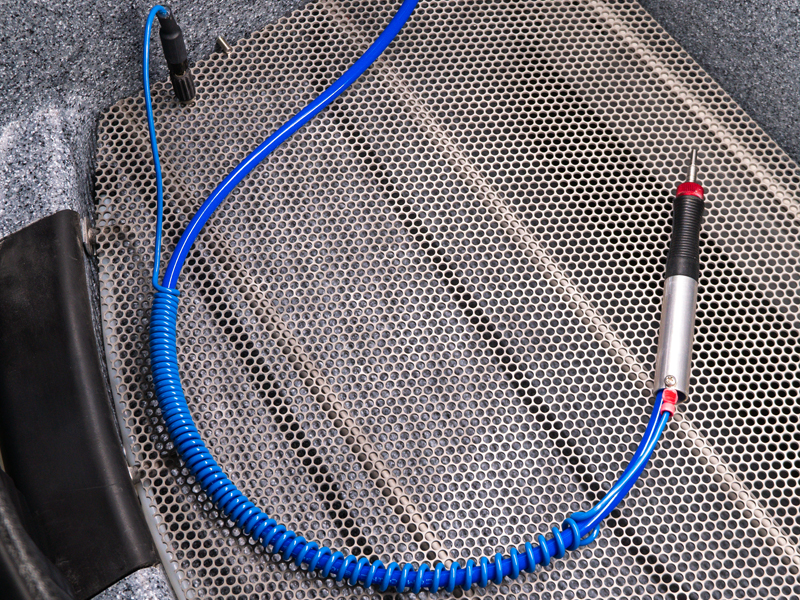

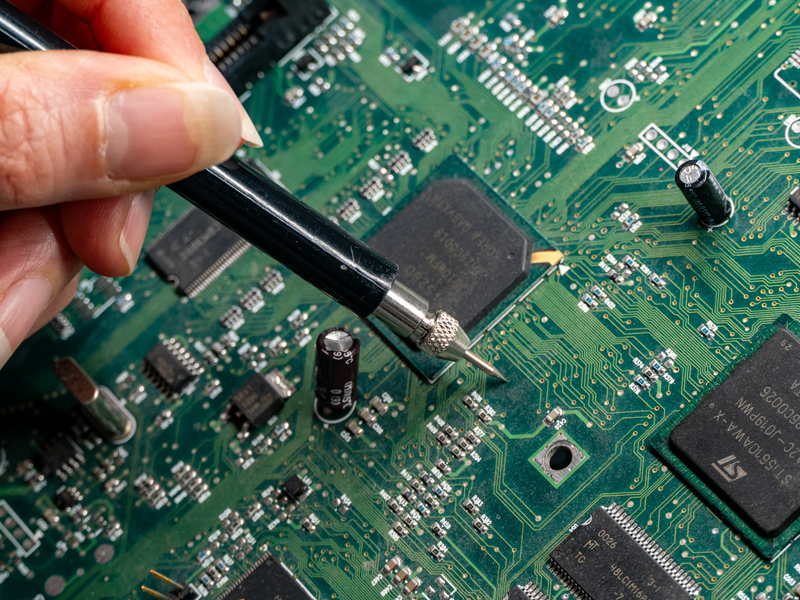

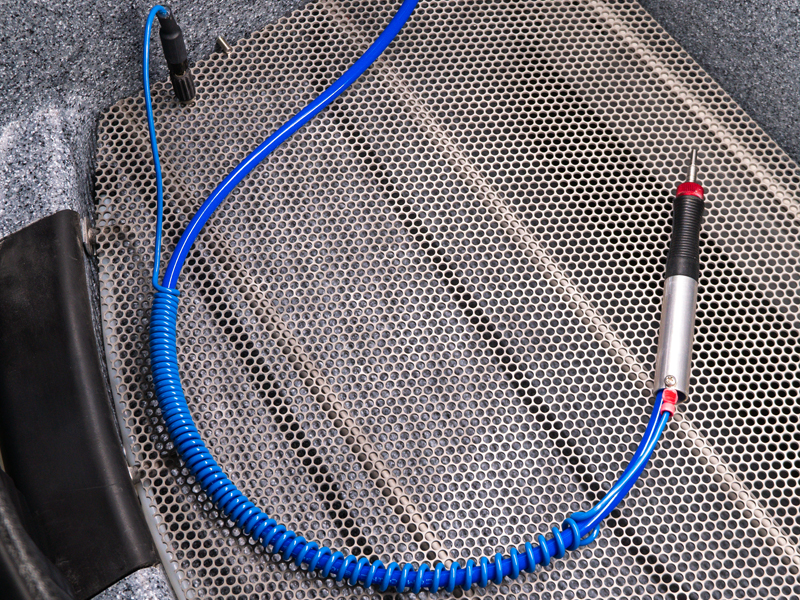

Needle Proble

Pierces through the coating and grounds a target trace when the defect is known to be an open trace with no conductive path to ground.

Grounded Handpiece

Works with the conductive nozzle to provide a conduit for static, sending it straight to the grounding jacks instead of onto a PCB.

Conductive Nozzle

Limits the potential for a charge to travel to the board from the abrasive hose. A conductive nozzle also blocks a charge that could arc from the operator. Should be used with the grounded handpiece.

Ionizer Bar

Floods the entire work chamber with ionized air to neutralize static build-up. Built-in sensors monitor the effectiveness of the ion flow and indicator lights alert the operator to any changes in operation.

CTR202-E Specifications

| Models: | CTR202-E-1 CTR202-E-2 |

|---|---|

| Available in: | 115V / 60Hz / 290W 230V / 50Hz / 290W |

| Size: | 30″ wide x 46″ high x 34″ deep |

| Interior Space: | 2.2 cubic feet 24″ wide x 14″ deep x 10″ (approx.) |

| Window: | Tempered glass opening (hinged) 23″ x 11″ |

| Weight: | 162 lbs / 73.5 kg |

| Lighting: | LED white and black light |

| Air Flow: | 500 SCFM |

| Filter: | HEPA- 99.97% efficiency on 0.3 micron-sized particles |

| Filter area: | 30 ft² |

| Inlet Air Pressure: | 80 psi air supply of 10 SCFM required for ESD models in addition to normal blaster supply |

| Sound level: | 68 dBA |

| Compatibility: | Works with all models of Comco micro-abrasive blasters |

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.

CTR202-E-1, CTR202-E-2, CTR201, CTR201-1, CTR201-2