Case Studies

Remove Excess Brazing Material from Cutting Tools

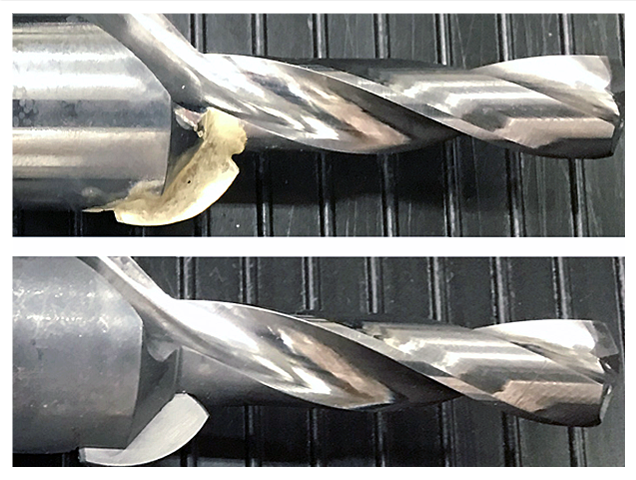

Goal: Get a clean surface without dulling or darkening

In order to make cutting tools stronger, manufacturers add a tungsten carbide insert into the surface of a tool steel bit. A pocket is machined out, the insert added, and then the insert and pocket are joined by the brazing process. This process can be messy and excess brazing material—usually an alloy filler–tends to smear around the tool steel, leaving a sloppy-looking part. The challenge of this application is similar to most selective cleaning applications: remove the unwanted material without impact to the part surface.

In this case, the goal is to remove any excess filler without damaging the carbide insert, darkening the part surface, or dulling the cutting features of the tool.

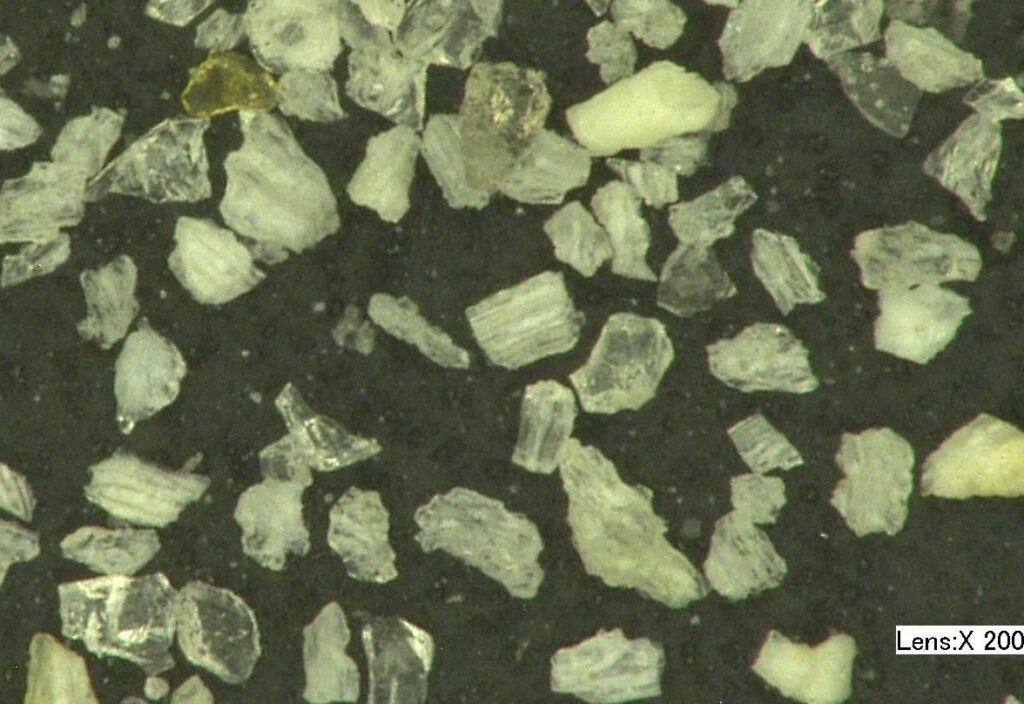

We tried a few different abrasives, nozzle, and blast pressure combinations on this application and found that 75 µ pumice at 60 psi is the most consistently effective blasting approach. Take a look:

Blast parameters in this demo

- Abrasive: 75 µ pumice

- Blast pressure: 60 psi

- Nozzle: 0.046” Hi/Performance

- Orifice: 0.030”

- Bypass: B

- Blast time avg: 2 minutes per part

Why clean with pumice?

The brazing material appeared hard to remove, so we opted for efficiency and started with two aggressive abrasives: crushed glass and white aluminum oxide. Both successfully blasted away the excess brazing material, and white aluminum oxide even left a nice matte finish on the cutting tool surface, but both abrasives showed signs of potential drawbacks.

If the blast pressure was too high or the nozzle was held too long in one spot, aluminum oxide slightly dimpled the finish of the tool. Crushed glass took much longer to remove the excess material than aluminum oxide, especially in sections with thick gobs of the alloy filler.

So, we tried pumice, and it surprised us! Pumice accomplished all of the goals of the application:

- Removed excess brazing material quickly

- Did not dull the cutting features

- Did not darken the surface of the cutting tool

- Left a matte finish

Pumice is a gentle cutting abrasive.

It is slightly harder than crushed glass and softer than aluminum oxide. Pumice has larger particles than aluminum oxide but produces a lighter impact, which makes it a great agent on tools that need to keep their sharp underlying features. In house, we refer to pumice as “AlOx-light”. Pumice is actually more abrasive than crushed glass, too, but it flows better, which makes it a more efficient option for this application.

Summary

There are three media options for removing excess brazing material from the surface of cutting tools: aluminum oxide, crushed glass, and pumice. In our sample tests, pumice stood out as the most efficient and reliable media. It took off the excess alloy filler efficiently without darkening or damaging the cutting tool features.

The media selection further enhanced the inherent precision and control already provided by micro-precision sandblasting. With the small, focused nozzle and a uniform mixture of air and abrasive, an operator can specifically target surface areas and control the removal process microns at a time.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.