Process Optimization

Startup Transient

Start up transient is a term we use to describe the variation in abrasive flow during the first few seconds of operation.

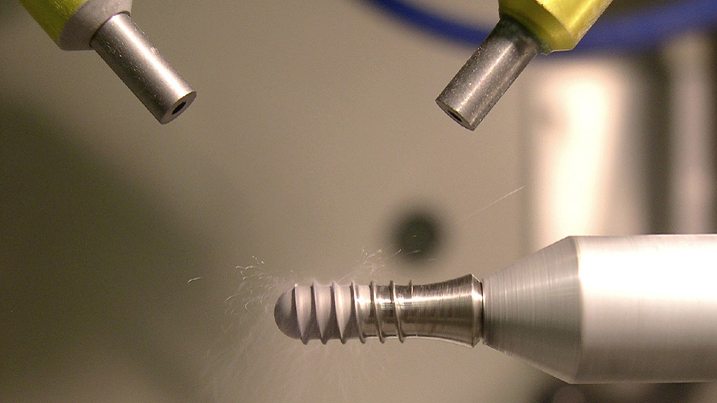

When the operator first steps on the footswitch to activate the abrasive stream, there is a 1-2 second period where the abrasive stream is visible before reaching steady state.

The transient is caused by two factors: residual abrasive in the abrasive hose and a sonic pulse that happens when the PowderGate valve is opened.

In normal operation, after the first 2 seconds, the abrasive reaches peak velocity and is traveling so fast that it is almost invisible to the naked eye.

Why can’t I see any abrasive coming out?

The principle of MicroBlasting is based on the idea of high velocity and low volume. The size of abrasive typically used in MicroBlasting is 15 – 100 microns. These fine particles accelerate to a much higher velocity than traditional sandblasting abrasives, fast enough that they are invisible.

You don’t wash a teacup with a fire hose

Where other sandblasting methods measure abrasive consumption in pounds consumed per minute, MicroBlasting is measured in grams. Combined with its higher velocity, each particle of abrasive becomes more efficient. Though it may not look like much, a 3-4 lb. bottle may last you quite a while depending on your application. Even in higher volume automate MicroBlasting applications, abrasive consumption might only run 10-20 grams of abrasive per minute.

So why then do I see abrasive at the startup?

Visualizing Start-up

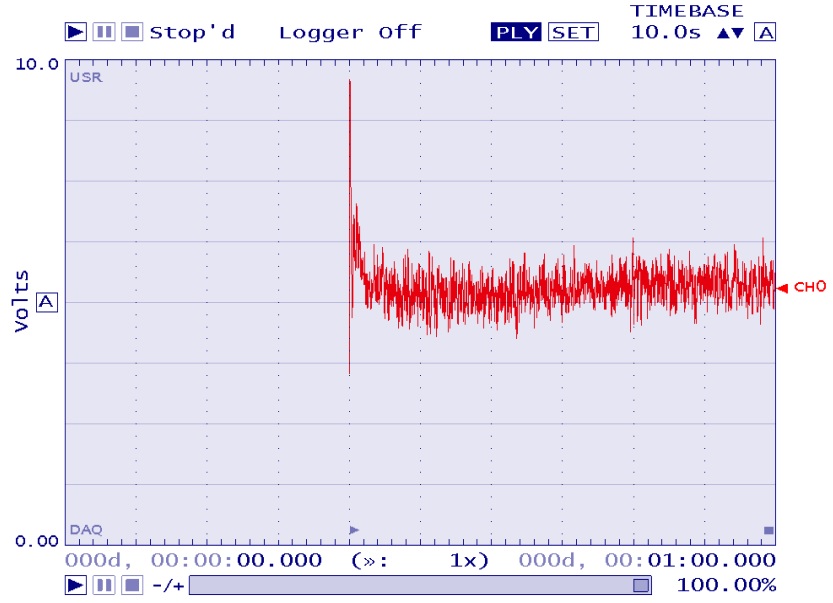

This chart illustrates the flow of abrasive through the hose out to the nozzle, using our Powder Flow Meter.

The initial spike is the moment the PowderGate is activated and a sonic pulse travels through the mixing chamber. During the next 1-2 seconds, air traveling from the PowderGate valve out to the nozzle is picking up residual abrasive. Once that abrasive is flushed through the nozzle, steady state flow is achieved.

In most applications, we recommend holding the nozzle pointed away from the part until steady stat is achieved. From that point the flow of abrasive is consistent and the results become very repeatable.

Why Pumping the Pedal is Bad

Sometimes operators will pump the pedal so they can see the abrasive — but, please, don’t do it! While you may see the abrasive as it spurts out, what you don’t see is the disservice you are causing to your machine. Also, it’s important to consider why you think it’s helping. If you just feel like there’s no abrasive, then, no worries, it’s there.