Equipment Updates

Static Sensitive Application?

MicroBlasting Can Handle That

(Safely and Economically)

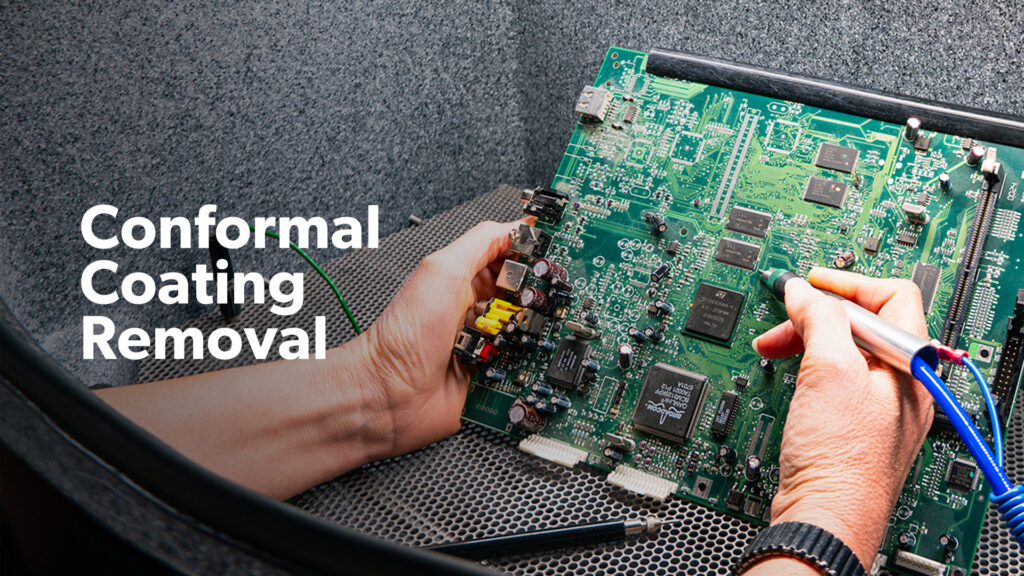

You might think micro-precision sandblasting, or MicroBlasting, is an unlikely tool for coating removal on static sensitive circuit boards and electronics. You might expect all that dry air and abrasive to kick up a spark, create a mess, or mar delicate compositions.

However, with the right adaptation to your equipment, you can greatly reduce the risks associated with ESD. MicroBlasting provides a gentle, precise and controllable approach to selectively remove parylene, epoxy, polyurethane, silicone, acrylic and more without danger.

Let’s look at how…

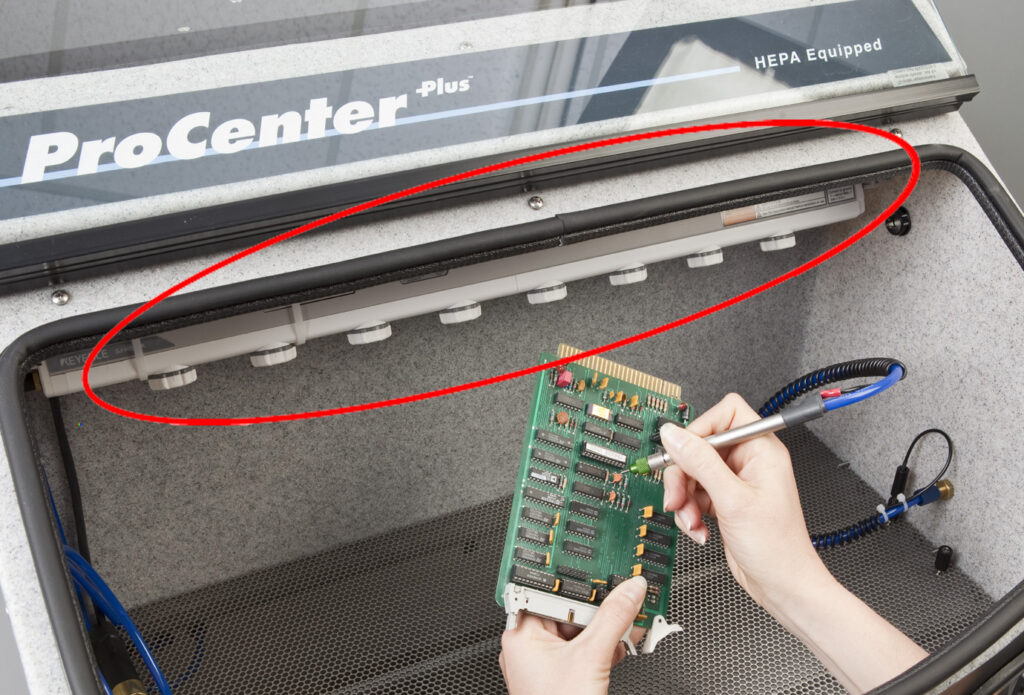

The ProCenter Plus Makes All the Difference

In the mid-1970s, we began designing ESD control workstations to accommodate static-sensitive applications. Four decades later, we adapted our compact and efficient all-in-one blasting center for conformal coating applications. The result is the CTR202-E ESD Control ProCenter Plus™.

Features of the ESD Control ProCenter Plus

- The Ionizer Bar floods the entire work chamber with ionized air to neutralize static build-up. Built-in sensors monitor the effectiveness of ion flow and indicator lights alert the operator to any changes in ion levels.

- Needle Probe pierces through the conformal coating to ground a target trace.

- Edge Grounding Bar grounds all edge pins on boards with edge connectors.

- Grounded Handpiece and Conductive Hi/Performance Nozzles work together like peanut butter and jelly. Each needs the other. Together, they provide a conduit for static, sending it straight to grounding jacks instead of onto the precious PCBs. (The conductive nozzles are VERY IMPORTANT. We cannot stress the importance of the conductive nozzle enough.)

- Grounding Jacks in the blast chamber provide convenient connection points for wrist-straps, edge grounding bar, and needle probes.

See Static Sensitive MicroBlasting in Action

This short video shows conformal coating removal using our AccuFlo® MicroBlaster and the ESD Control ProCenter Plus™.