Case Studies

Thermocouples

What is a Thermocouple?

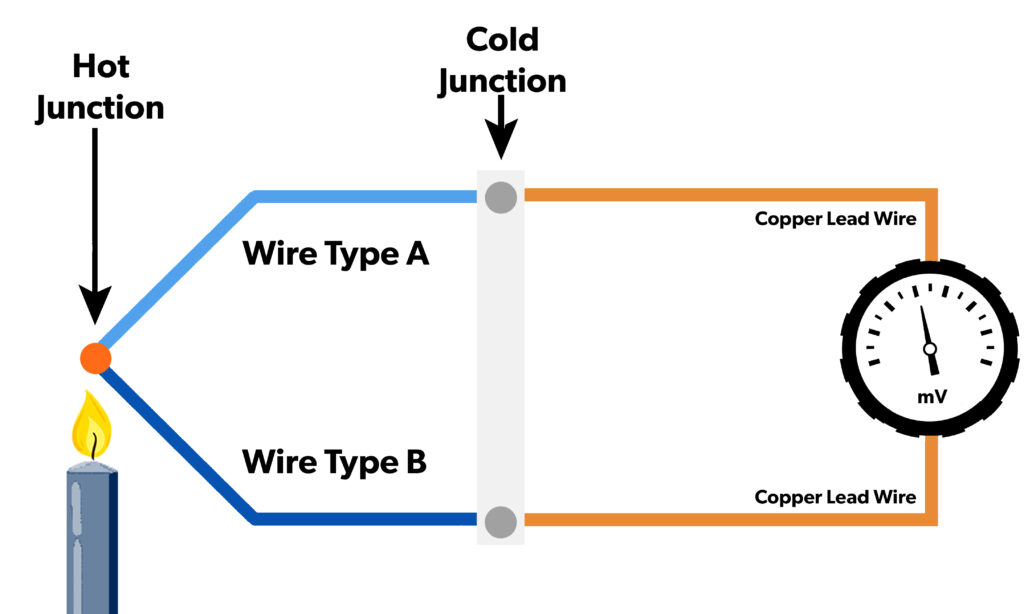

What is a Thermocouple? A thermocouple is a thermoelectric device for measuring temperature. They are used in a wide range of applications, including homes in gas stoves and furnaces as well as in industrial processes such as electric power generation, food and and beverage processing, aircraft engines and more.

A thermocouple consists of two different types of metals joined together at one end (hot junction) and terminated at another end (cold junction). When heated or cooled, a voltage created between the two junctions can be correlated back to the temperature.

A Magnesium oxide thermocouple is one of the most common types of thermocouple. It has become the standard powder insulation for temperature sensors and can withstand very high temperatures.

How is a Mgo Thermocouple made?

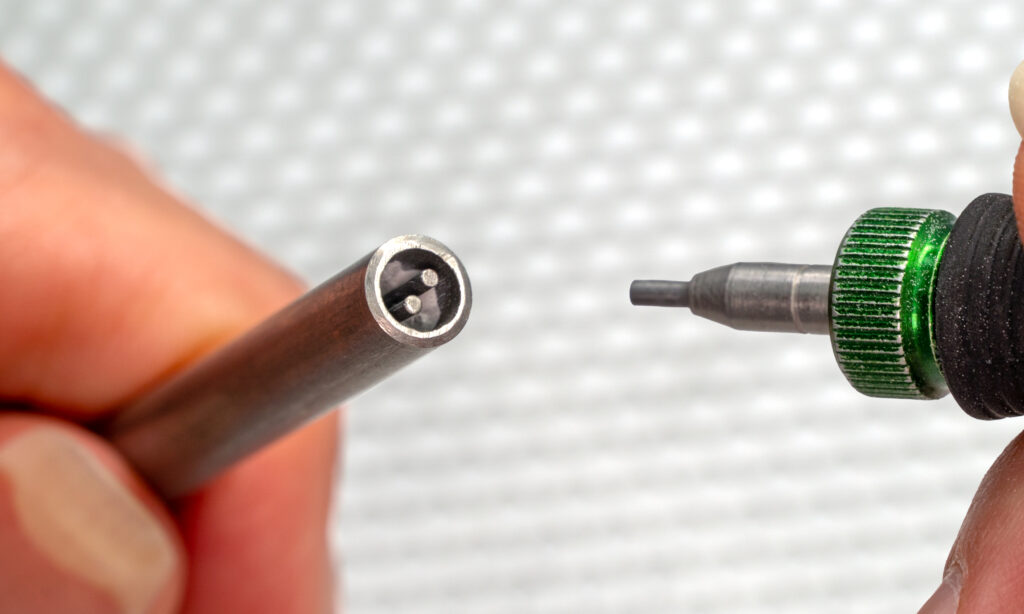

A MgO thermocouple consists of a thermocouple element encased in a metal sheath and hard-packed with magnesium oxide mineral insulation. It is constructed using a long tube that is filled and then cut to size. This enables the insulation to be packed for several thermocouples in one step, providing consistent packing throughout the tube. Next, the thermocouples are cut to size. At the end of the thermocouple, a small section of MgO must be removed to expose the temperature sensor wires. This is where the hot junction is made.

MicroBlasting provides an efficient method for removing small amounts of MgO to expose these wires.

Why MicroBlasting?

An operator can quickly erode a small portion of the MgO insulation to expose the ideal amount of wire to form the hot junction for the thermocouple. It is a simple and forgiving process that can be easily learned. For greater throughput, Comco offers automated solutions. Watch the video below to see both methods.

MicroBlasting Parameters

- Abrasive: 50µ aluminum oxide

- Nozzle size: .030″ Hi/Performance

- Pressure: 60 PSI

- Tank orifice: 0.25″

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.