Maintenance & Troubleshooting

Understanding Modulator Wear and Repair

THE COMCO MODULATOR

OUR PATENTED TECHNOLOGY EXPLAINED

Do you know what sets a Comco micro-precision sandblaster apart from others? In short, It’s our modulator. This pulsing heart of our system transforms the technology from a dirt sprayer into a precision tool.

Think of it like…

- A spray-paint can: If the spray nozzle clogs or if the paint-can lacks a solid spraying mechanism, the targeted canvas surface may end up with blotches of paint. Comco’s modulated feed produces a steady mixture of air and abrasive that prohibits clogs, clumping, bursts of abrasive, sparse mixtures, etc. The steady stream of abrasive produces a uniform and repeatable surface finish.

- A salt shaker: the technology of other blasters relies on a series of components that is similar to a salt shaker. They shake abrasive out into the air stream, and that means an unreliable amount of abrasive exits the nozzle. Comco’s blasters feature a modulator that pulses consistently, pulling the same amount of abrasive particles into the abrasive stream with every pulse.

Watch our quick video to understand how it works.

3 Ways to Identify a Worn Modulator

Rattle vs. Hum

A good modulator hums. A worn modulator rattles. The gradual shift from one sound to the other over time may be hard to notice, so we usually recommend tracking blast hours and abrasive flow.

Blast Hours

If you are into preventive maintenance, we recommend tracking blast hours to schedule a replacement.

- The AccuFlo modulator has a lifespan of 5,000 blast hours

- MicroBlaster, PowerFlo and DirectFlo modulators should be replaced every 2,000 hours of operation.

Low Flow

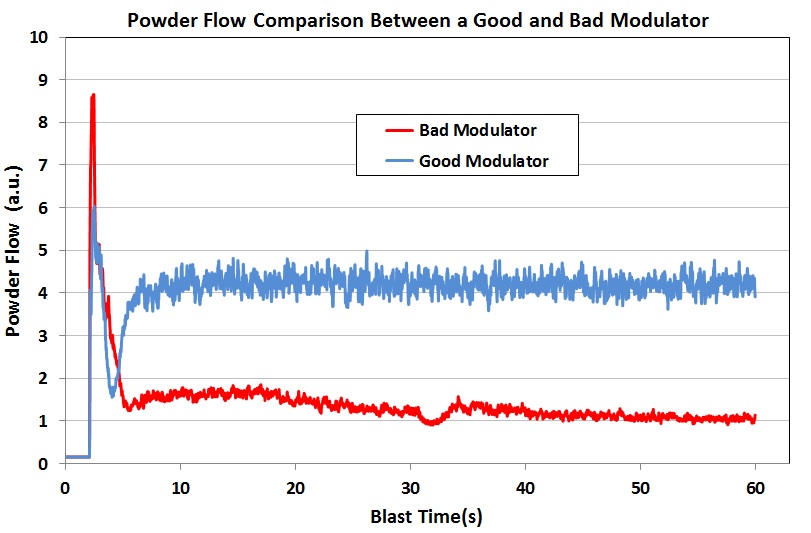

It is time to replace the modulator when you no longer get strong pulses of air into the tank. You will see the outward manifestation in your abrasive flow. When a modulator is too worn to seal, your abrasive flow starts out strong, but within 3-5 seconds drops off to almost nothing.

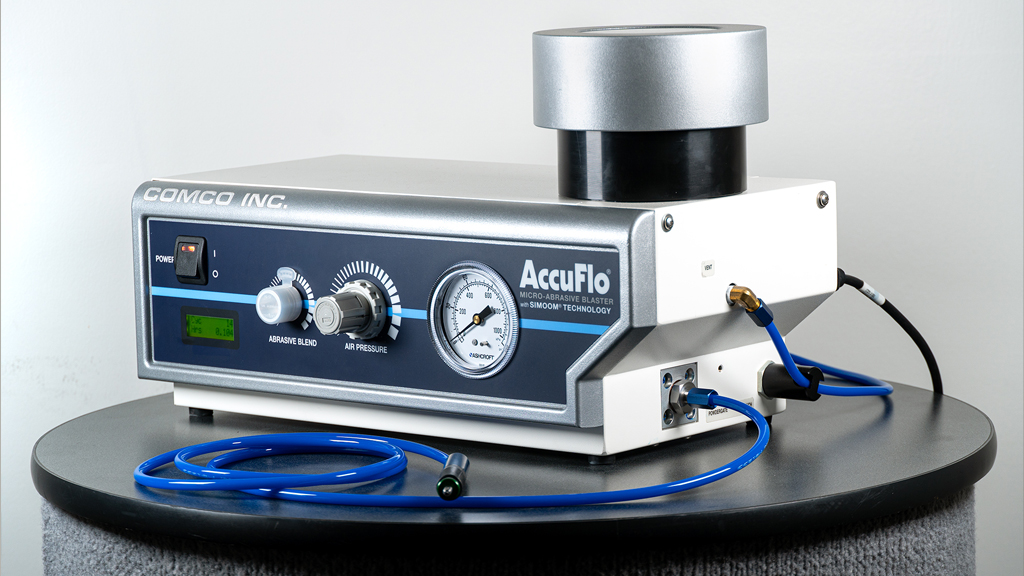

The AccuFlo® has a Better Modulator

We significantly improved the design of the modulator in our latest MicroBlaster, the AccuFlo. These improvements dramatically increase the modulator’s lifespan to 5,000 blast hours. (The modulator on our standard MicroBlaster should be replaced every 2,000 blast hours.)

Why is it better?

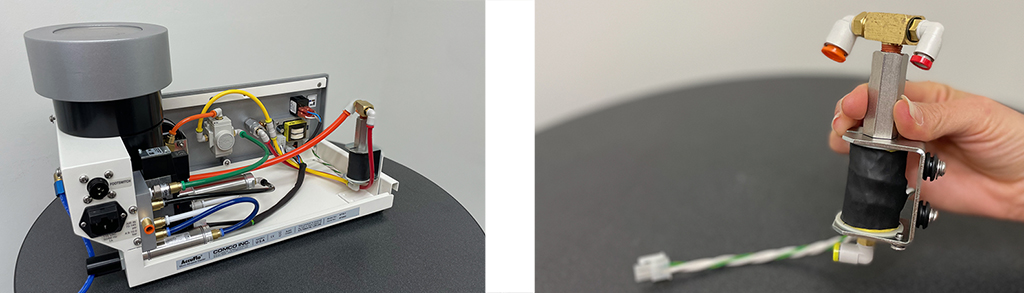

- Location: the modulator sits further away from the tank to reduce the potential for abrasive contamination.

- Orientation: the vertical orientation reduces the potential for uneven wear that forms on the core and the body when the modulator lies horizontally like it does in our other blasters.

- Easy Replacement: the whole unit can be removed with 2 Philips screws and push-connect fittings. All hoses on the AccuFlo are color-coded to improve confidence in assembly.

What to order?

It’s a good idea to have a backup on-hand and avoid production interruption. To order a replacement modulator assembly for your blaster, contact Customer Service via email or call 1-818-841-5500. Order part number:

-

MB2250-1 (For AccuFlo 115V models)

-

MB2250-2 (For AccuFlo 230V models)

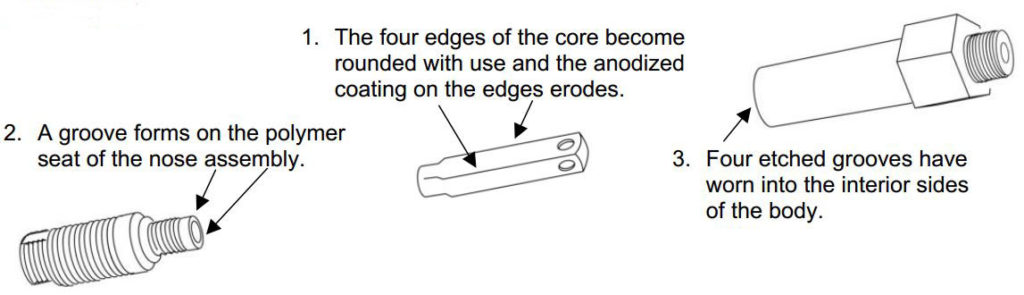

WHY DOES THE MODULATOR NEED MAINTENANCE?

The modulator is a precision valve that operates at 60Hz in a harsh environment. The combination of rapid cycling in an abrasive environment will cause wear over time. The modulator on our standard MicroBlaster should be replaced every 2,000 blast hours.

What to order?

It’s a good idea to have a backup on-hand and avoid production interruption. To order a replacement modulator assembly for your blaster, contact Customer Service via email or call 1-818-841-5500.

MB1301-2* (MicroBlaster® modulator housing assembly)

*Typically the cylindrical housing assembly within the coil needs to be replaced on the MicroBlaster, PowerFlo and DirectFlo; not the coil itself.

WHY DOES THE MODULATOR NEED MAINTENANCE?

The modulator is a precision valve that operates at 60Hz in a harsh environment. The combination of rapid cycling in an abrasive environment will cause wear over time. The modulator on our standard DirectFlo and PowerFlo blasters should be replaced every 2,000 blast hours.

What to order?

It’s a good idea to have a backup on-hand and avoid production interruption. To order a replacement modulator assembly for your blaster, contact Customer Service via email or call 1-818-841-5500.

PF2040* (DirectFlo™ / PowerFlo® modulator housing assembly)

*Typically the cylindrical housing assembly within the coil needs to be replaced on the MicroBlaster, PowerFlo and DirectFlo; not the coil itself.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.