Process Optimization

Nozzle Fixturing: A Quick Prep

Whether you’re transitioning your manual MicroBlasting process to automation, or working with automation from the start, this guide provides the intro to nozzle fixturing basics you need to know.

Consider the Nozzle

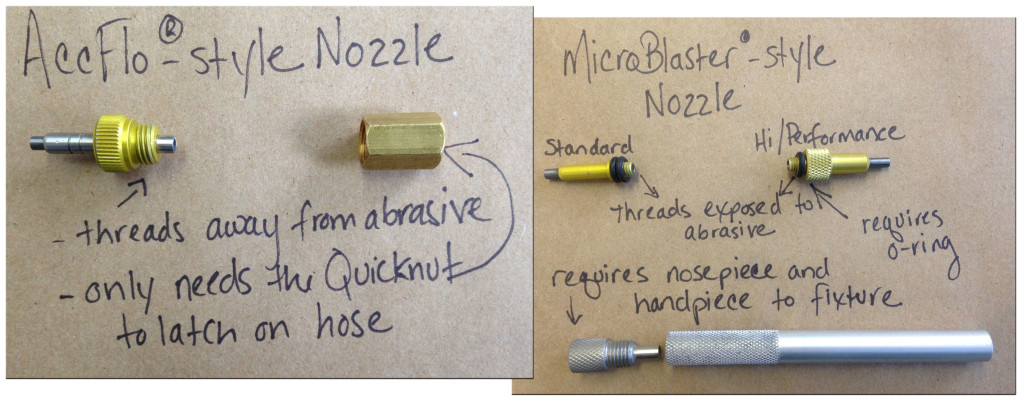

The crux of any automated system is the nozzle fixture. Every fixture must hold its nozzle(s) accurately. We highly recommend conducting your MicroBlasting research with AccuFlo®-style nozzles*. We primarily use these nozzles in our automated systems, because they are easier to replace, last longer, and provide more consistent and repeatable results.

*There are exceptions to their use. Some applications require the PowerFlo® and thus, PowerFlo-style nozzles. Another reason to consult with our Sales Team from the outset!

Fixturing Guide

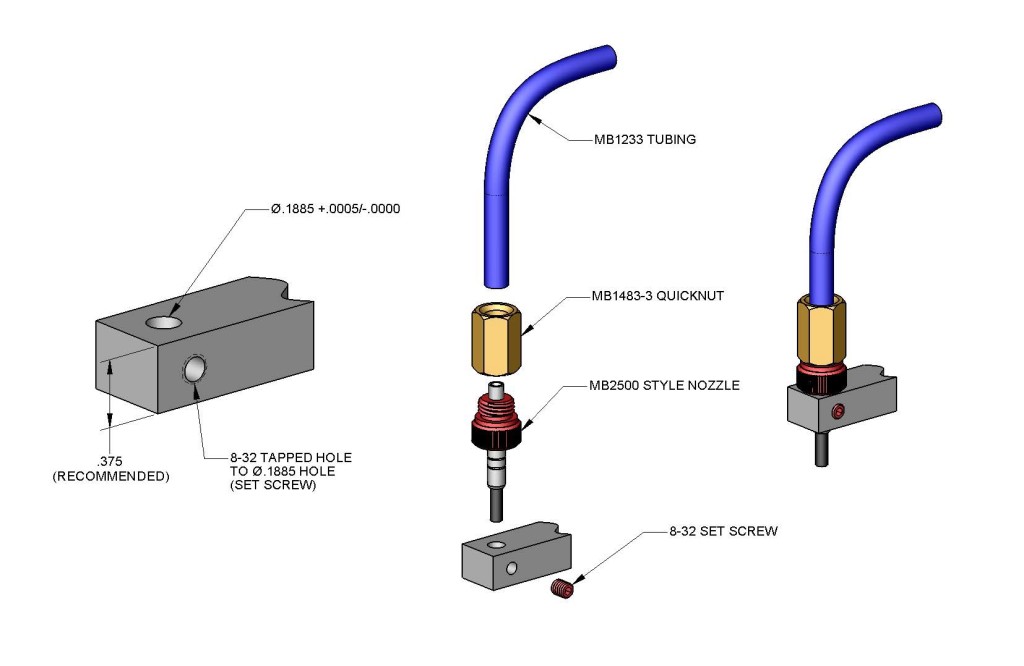

for use with 1/4″ abrasive hose

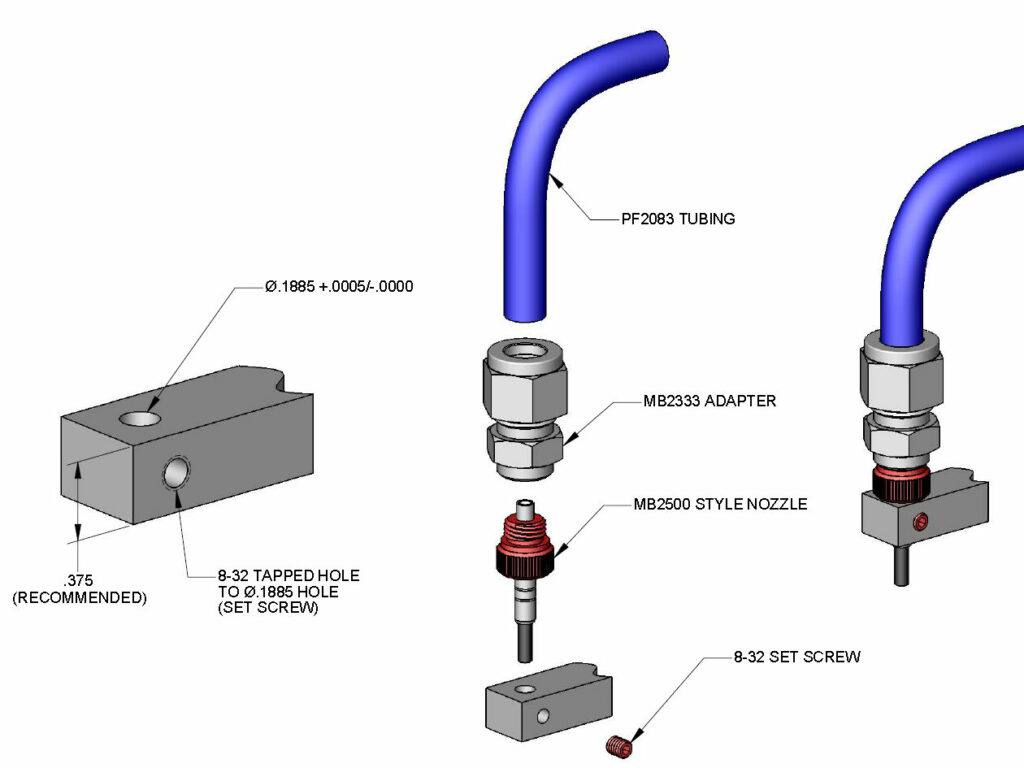

for use with 3/8″ abrasive hose

The Benefits of AccuFlo-style Nozzles

- Better Threads: AccuFlo-style nozzle threads are out of harm’s way. This sensitive wear point is blocked from the abrasive stream: a small, but significant factor that extends the life of the nozzle.

- QuickNut Compatible: finger-tight to lock the abrasive hose onto the back of the nozzle

- Consistent Alignment: Each part in the nozzle and its fixture introduce a potential impact to repeatability. More parts equate to more adjustment with each nozzle replacement which means more variation in results. AccuFlo nozzles only have 2 pieces: the Quicknut and the nozzle itself. No nosepiece. No handpiece. No o-ring. The nozzle tip is held at its base by the fixture, keeping the nozzle-to-target distance consistent through replacement.

Why does nozzle distance even matter? Our previous post, How Far Away Should I Hold the Nozzle From the Targeted Part? walks in-depth through this essential question.

Our Design Approach

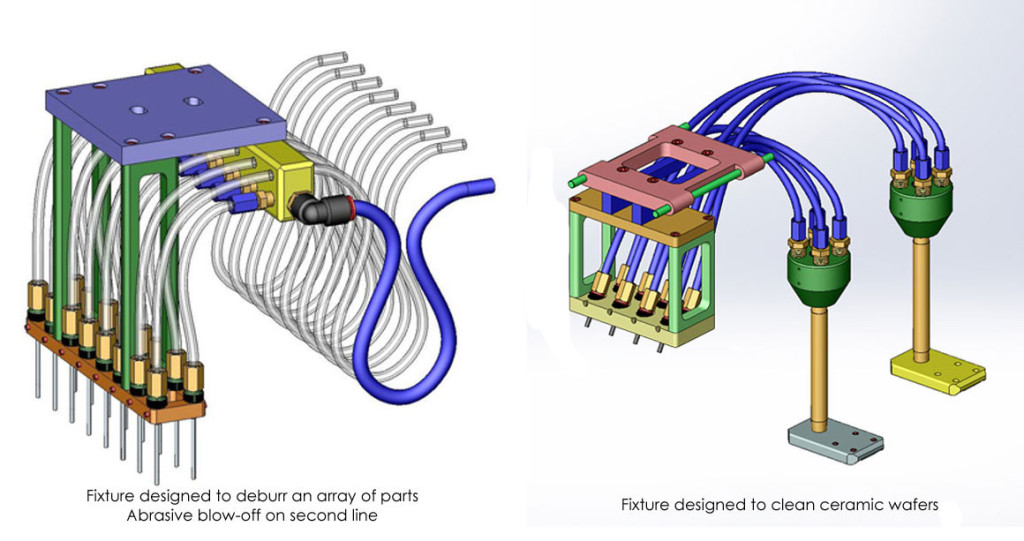

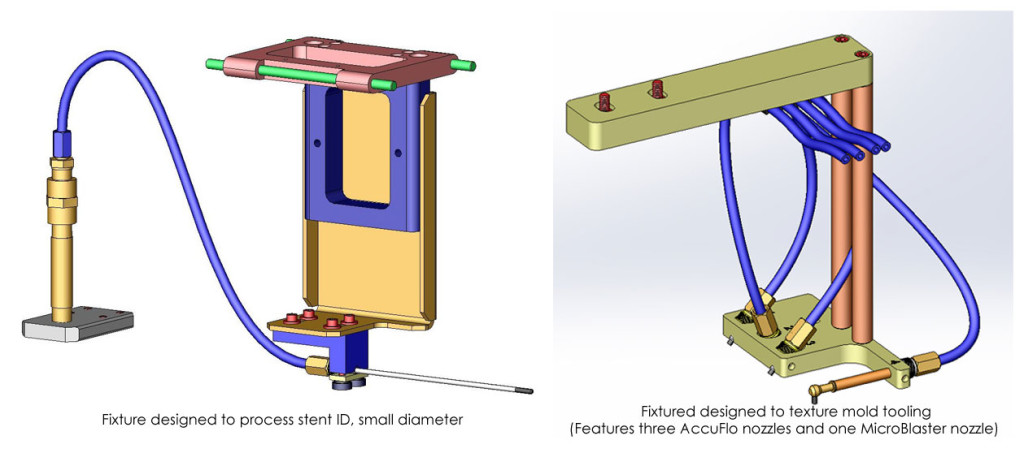

Each automated application fixture is unique and part specific. You’ll see what we mean below. Our consistent goals across designs are:

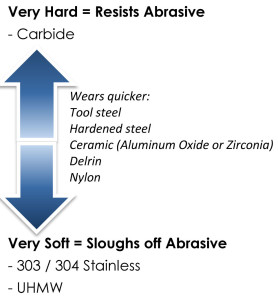

- Limit the components that come into contact with abrasive.

- Use materials that are hard enough to resist abrasive or soft enough to slough off energy that the abrasive transfers.

- Make sure wear items are easy to replace.

- Limit disturbance on nozzle-to-target alignment.

Consider the Nozzle Fixturing Possibilities

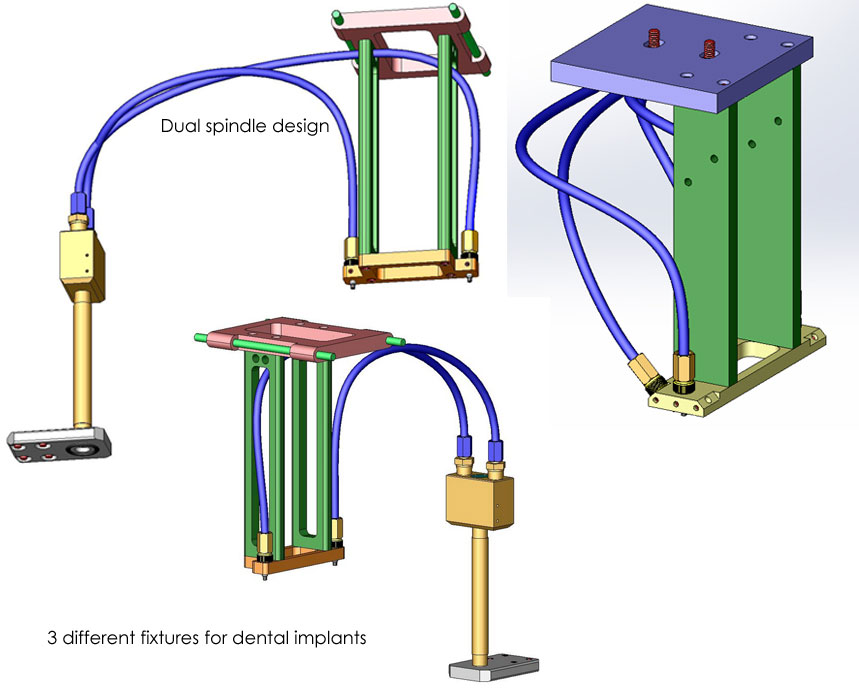

Our engineers have built an array of blast assemblies for to suit most applications. Here is a quick gallery featuring popular examples of the available nozzle fixtures to help you and your team brainstorm possibilities.

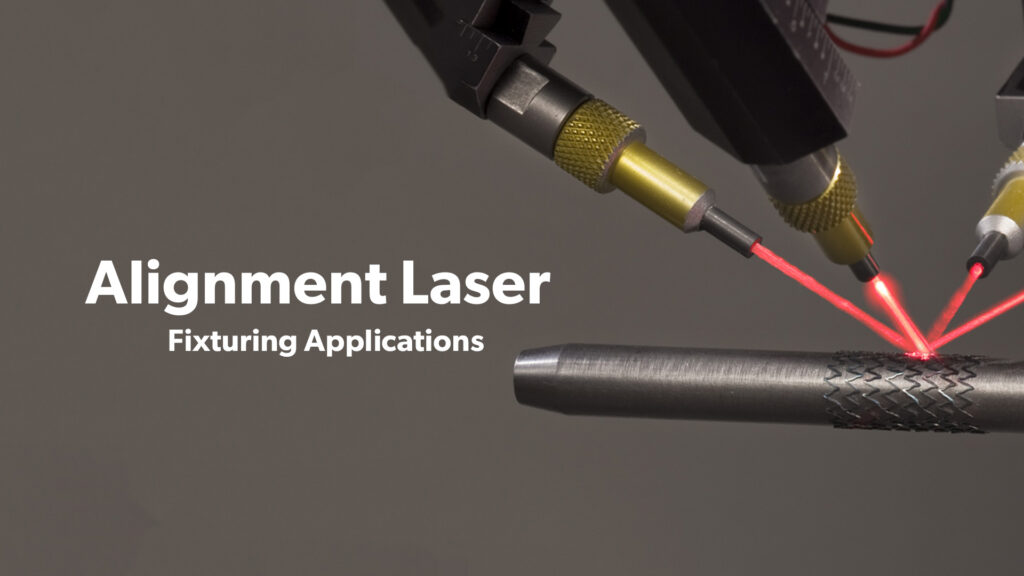

Nozzle Alignment Laser

Take it one step further with the Nozzle Alignment Laser. This component attaches at the back of the nozzle and places a dot on the part’s surface where the abrasive will strike. Once alignment is set, simply remove the Nozzle Alignment Laser and attach the abrasive hose. See video below: