Maintenance & Troubleshooting

How to tell if your Nozzle is Worn

Have you noticed a change in your MicroBlasting results?

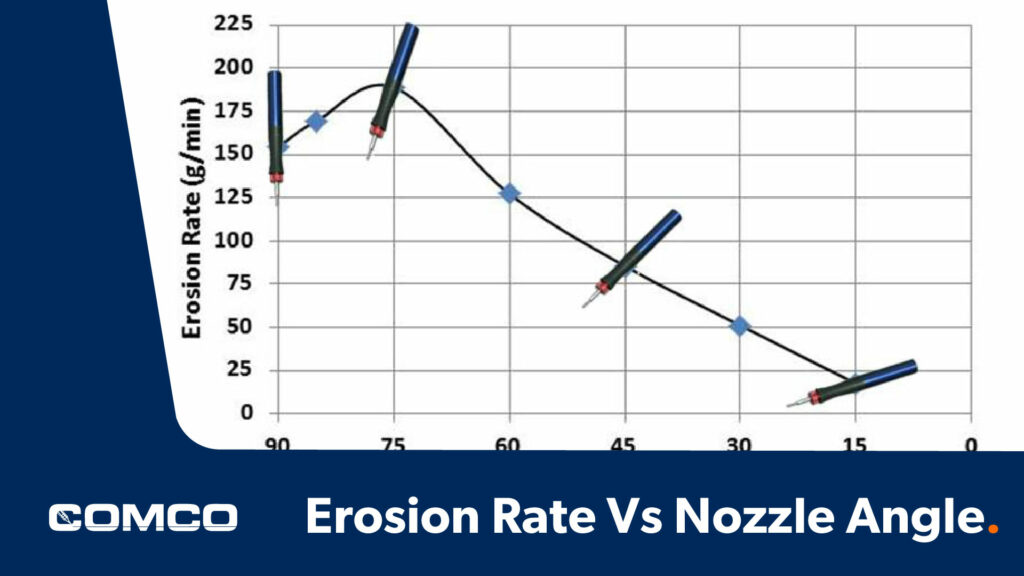

As your nozzle wears, it gradually loses the tight focus. Some applications you can keep using a nozzle until it blows out the side. For others, a few thousandths wear will cause part failure. Abrasives, like aluminum oxide, will wear out the nozzle faster than softer ones, like crushed glass. So how do you know when it’s time to replace it?

We’ve created three simple test methods to ensure your get the best use out of your nozzles. Check out the video below for a deeper explanation into those methods.

Three Ways to Test Your Nozzle:

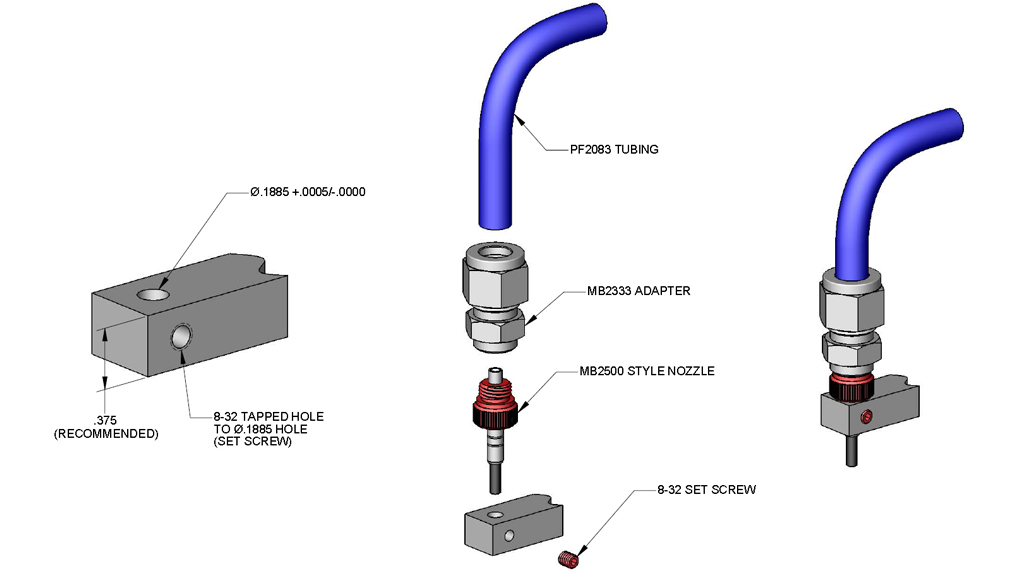

- Pin Gauge – Using a pin gauge that is 10-15% larger than size of the nozzle, test to see how easily the pin slides through the nozzle. If the pin can not fit through the nozzle entrance, then the nozzle is likely new, and does not need to be replaced. If it slides all the way through, the nozzle is worn out and needs to be replaced.

- Checking Surface Results – If you start to see inconsistencies in your surface results, the nozzle is ready to be replaced.

- Tracking Abrasive Consumption – When you notice your results start to diminish, note your abrasive amount and use that as a marker to replace your nozzle every time it gets to that level.

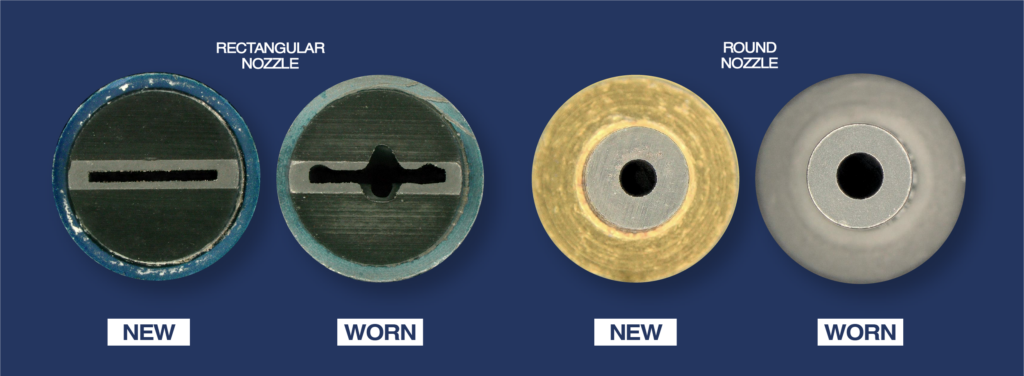

Different Nozzle Types, Different Wear Results:

- Round nozzles will wear in a cone shape.

- Rectangular nozzles will wear in either a football or a dogbone shape – Once wear starts to form, at either the middle (football) or edges (doggone), then it quickly erodes those areas. This uneven wear dramatically shortens the life of the nozzle. Whenever Possible a round nozzle should be used.

Hi/Performance Nozzles are the most efficient option because of their longevity, focus, and flexibility. They will last 3-5 times longer, and in result, allow you to change your nozzle less frequently.

*Note for sodium bicarbonate users – Ignore everything from above! Sodium bicarbonate has a shrinking effect on your nozzle caused by buildup on the nozzle walls. To clean your nozzle, use vinegar or a light acid. See this post for more information for blasting with sodium bicarbonate.