Equipment Updates

AutoFill Makes Refills Quick, Clean and Automatic

Blasting All Day? Running an Automated System Round-the-Clock?

After blasting for long hours, a normally quick pour can turn into a comedy of errors. Operators tire, go on autopilot, and forget to refill. Worse, they may rush refills and get sloppy. This is when accidents—like abrasive spills—happen.

Spills present critical safety hazards, especially on floors that camouflage micro-abrasive particles. (Ever spilled glass bead on white linoleum?) Then there’s the matter of cleaning the tank threads, which wayward abrasive particles grind down…. are you exhausted yet?

By the time your operator returns to the blasting task-at-hand, they may need more time to find where they left off or they might settle for uneven results.

Running out of abrasive on an automated application is more problematic. If the system runs out of abrasive, the blast program aborts, which may mean a loss of product or rework.

AutoFill Keeps Production Humming

AutoFill, as its name implies, automatically refills the abrasive tank so your operator does not have to. And it refills faster, cleaner and more efficiently than most experienced operators.

Why?

- It senses when the tank is low—eliminating time lost to constant checking or running out of your abrasive mid-blast cycle.

- The filling operation is totally automatic and requires no operator involvement—reducing the potential for error or variation.

- It provides a brief respite without distraction, so your operator can focus on the project.

- Media moves from a sealed drum to the sealed abrasive tank, with no exposure to moisture and environmental contaminants.

- No pouring necessary—no spills!

- AutoFill often performs the task faster than an operator.*

*Feel free to prove us wrong on this last point. A refilling contest sounds fun!

What’s in the AutoFill?

AutoFill has three primary sets of components: the AccuFlo Accessories, the Vacuum Generator, and the Powder Drum Kit.

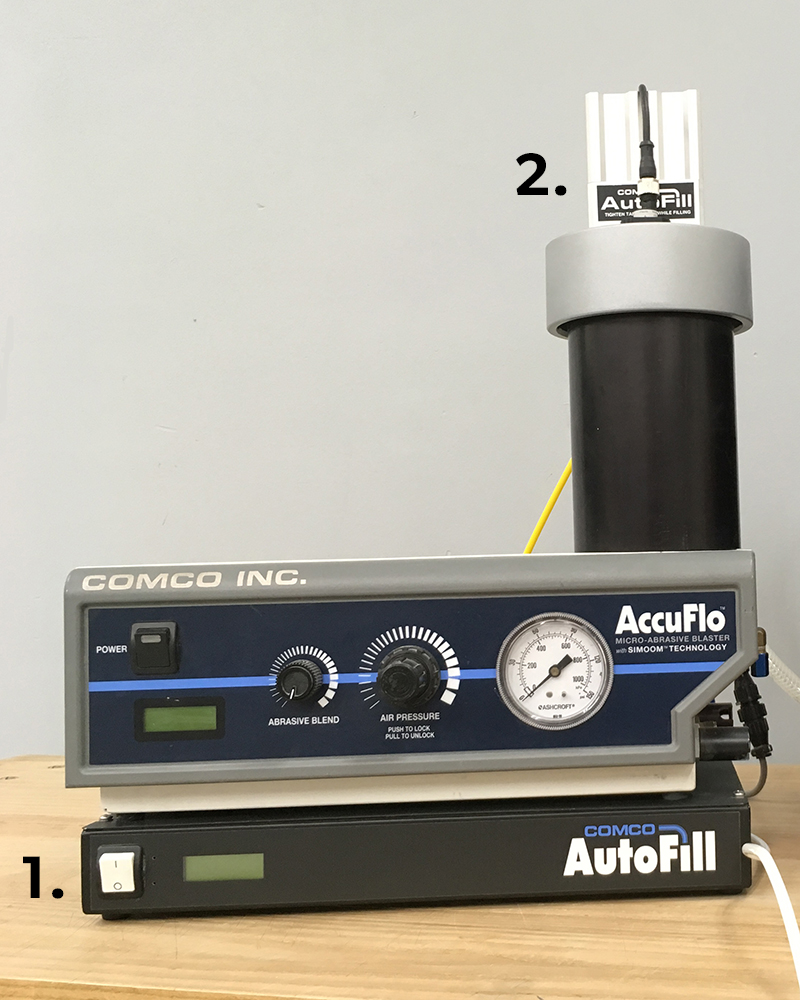

1. The Control Box

This Control Box sits under the AccuFlo and is responsible for controlling all aspects of the filling operation. The LCD on the Control Box displays all communication, including any with a host controller on an automated system.

It lists all current conditions such as blasting, filling and the states of the optional inputs. While filling, it lists how many fill cycles have been completed and how long the current fill cycle has been running.

Note: The fill cycle counter is useful for planning routine maintenance.

2. The Tank Cover with Sensor and PowderGate® Valve

The AutoFill comes with its own tank cover, replacing the standard AccuFlo tank cover. AutoFill’s tank cover has a large PowderGate valve that controls the flow of abrasive from the Powder Drum and a sensor that signals when it is time to stop filling.

The Vacuum Generator with HEPA filtration provides the necessary suction to move abrasive from the Powder Drum to the AccuFlo.

Each kit comes with a Drum Vibrator, an Abrasive Flow Control and a Drum Outlet capable of feeding 1 or 2 AccuFlos. The Drum Vibrator only needs to be purchased once and can be used on each successive Powder Drum.

The kit is designed to fit our 15-gallon bulk-powder drum. Abrasive stays sealed in an airtight plastic bag while inside the drum, reducing the opportunity for environmental contamination.

How Does AutoFill Work?

The Drum Vibrator moves abrasive from the conic bottom of the Powder Drum into an air stream that passes underneath the stored abrasive. The Vacuum Generator then draws abrasive from the Powder Drum into the AccuFlo tank. It’s that simple.

Note: When multiple AutoFills are controlled by an external host such as a PLC, multiple AccuFlos can feed off a single Powder Drum.

AutoFill is Smart

AutoFill monitors the blast cycle. Based on factory settings, AutoFill requests a “Fill Cycle” after 30 minutes of blasting. It does not interrupt blasting; it simply waits 2 seconds after the blast cycle ends and then begins filling.

AutoFill Senses

AutoFill uses a sensor to gauge when the abrasive tank is full. When the tank is full, AutoFill stops filling and tells the AccuFlo to pressurize in preparation for blasting. Fill times range between 1-3 minutes, depending on the type of abrasive in use and the lengths of hoses connecting components.

AutoFill is Customizable

The timers on the AutoFill are customizable. If you run a rich media flow, you can shorten the 30-minute countdown timer to avoid running the tank empty. If your blast programs consist of several blast cycles with gaps in between, you can extend the 2-second delay to avoid refills during the program gaps.

AutoFill can rely on its internal sensors and timers and run independently, or it can be controlled externally using three inputs and outputs:

- The “Force Fill” input allows a host PLC or automatic machine to initiate the “Fill Cycle.”

- The “Inhibit Fill” input stops the AutoFill from refilling under any circumstance.

- The “Ok-to-Blast” output indicates that the countdown timer has not reached zero, and the blaster is available for blasting.

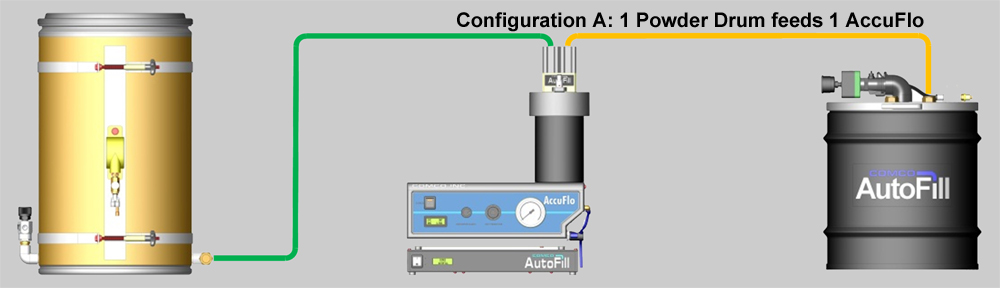

Possible AutoFill Configurations

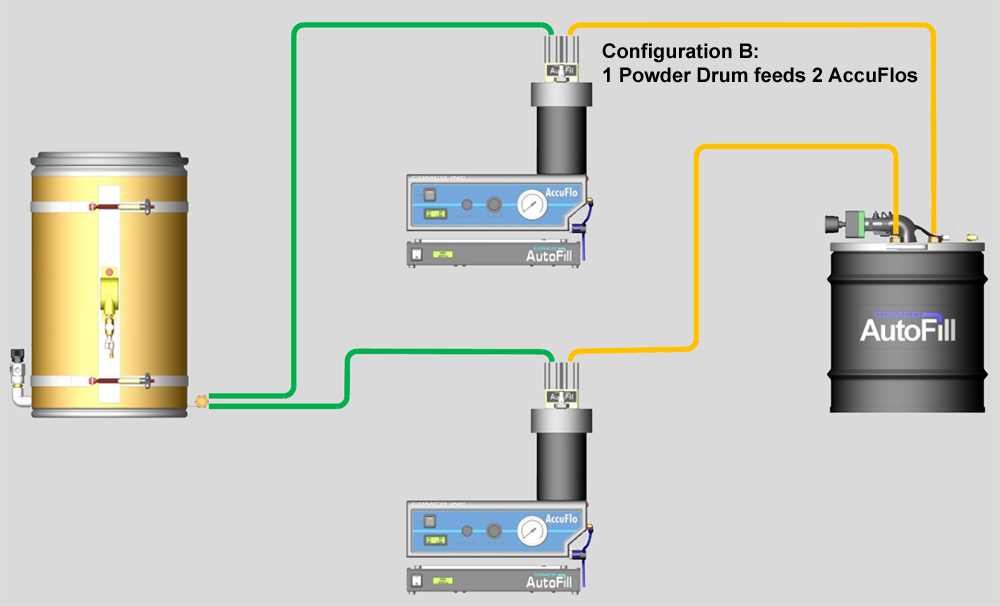

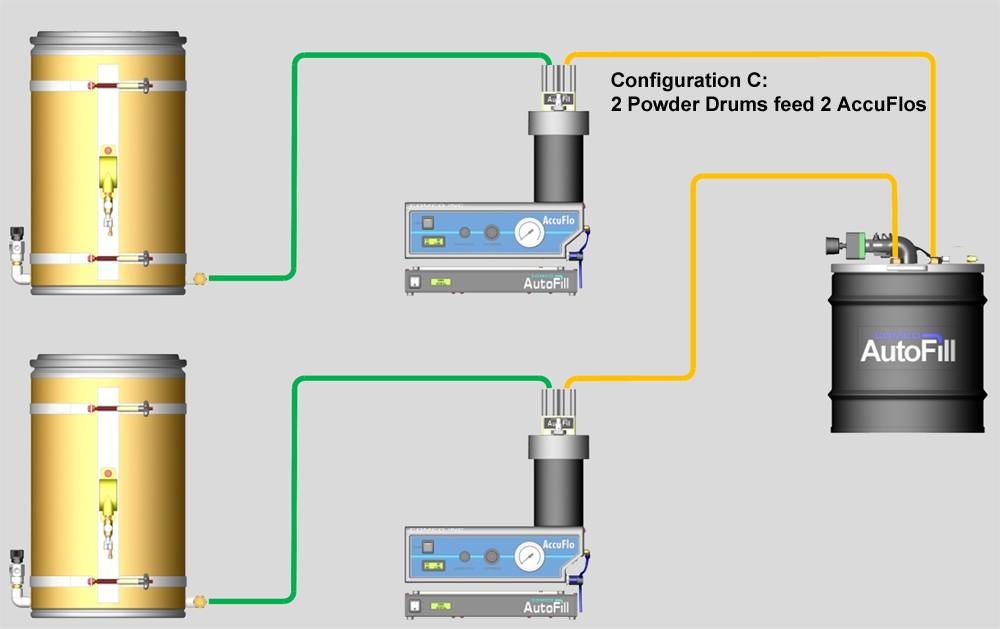

Each Powder Drum can feed up to 2 AccuFlos. Each Vacuum Generator can fill up to 2 AccuFlos. This combination adds up to create the 3 following AutoFill configurations:

1 Powder Drum feeds 1 AccuFlo

1 Powder Drum feeds 2 AccuFlos

2 Powder Drums feed 2 AccuFlos

How do I set up AutoFill?

See how the individual components are connected in this video.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.