Precise MicroBlasting Technologies for Medical Applications

If you clean stents, deburr needles, texture implants or machine graphite from mechanical heart valves, you know the importance of control. Medical manufacturing must meet strict standards, which means medical implants and devices require a surface refinement tool that delivers pinpoint precision and repeatable results. We’ll work closely with you to land on custom solutions for your medical engineering and manufacturing needs.

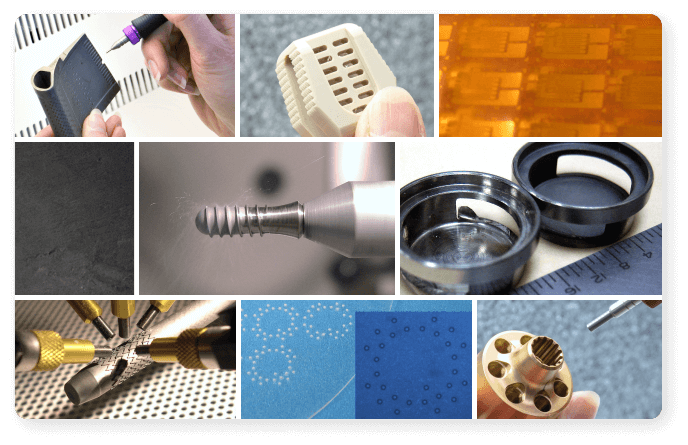

Explore medical parts used in the body that have been manufactured and optimized with our MicroBlasting systems

PEEK spinal implants

What? – Remove fine feather burrs

Why MicroBlasting? – Operators easily follow the contours of an implant to remove burrs quickly and safely without causing dimensional changes.

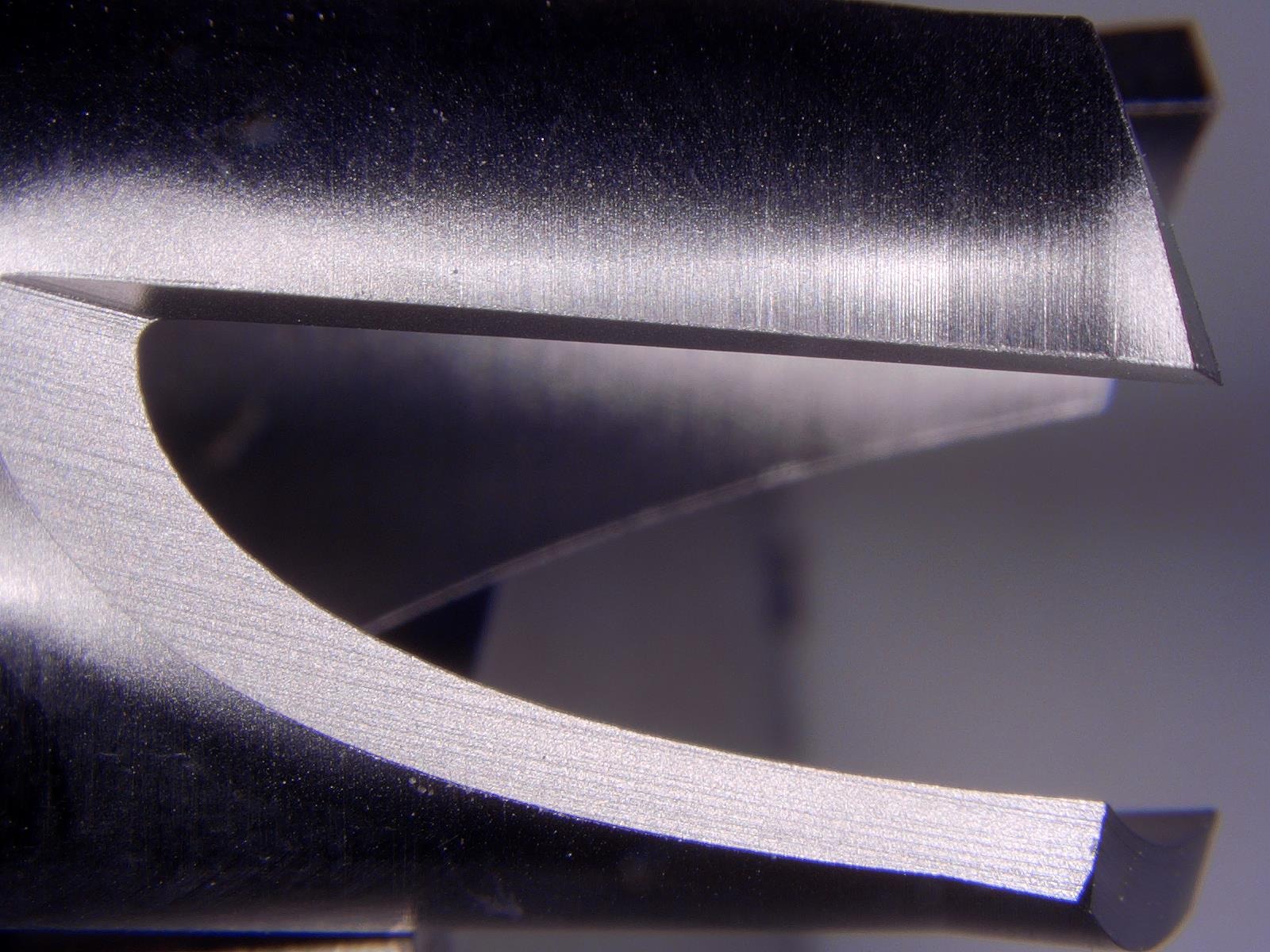

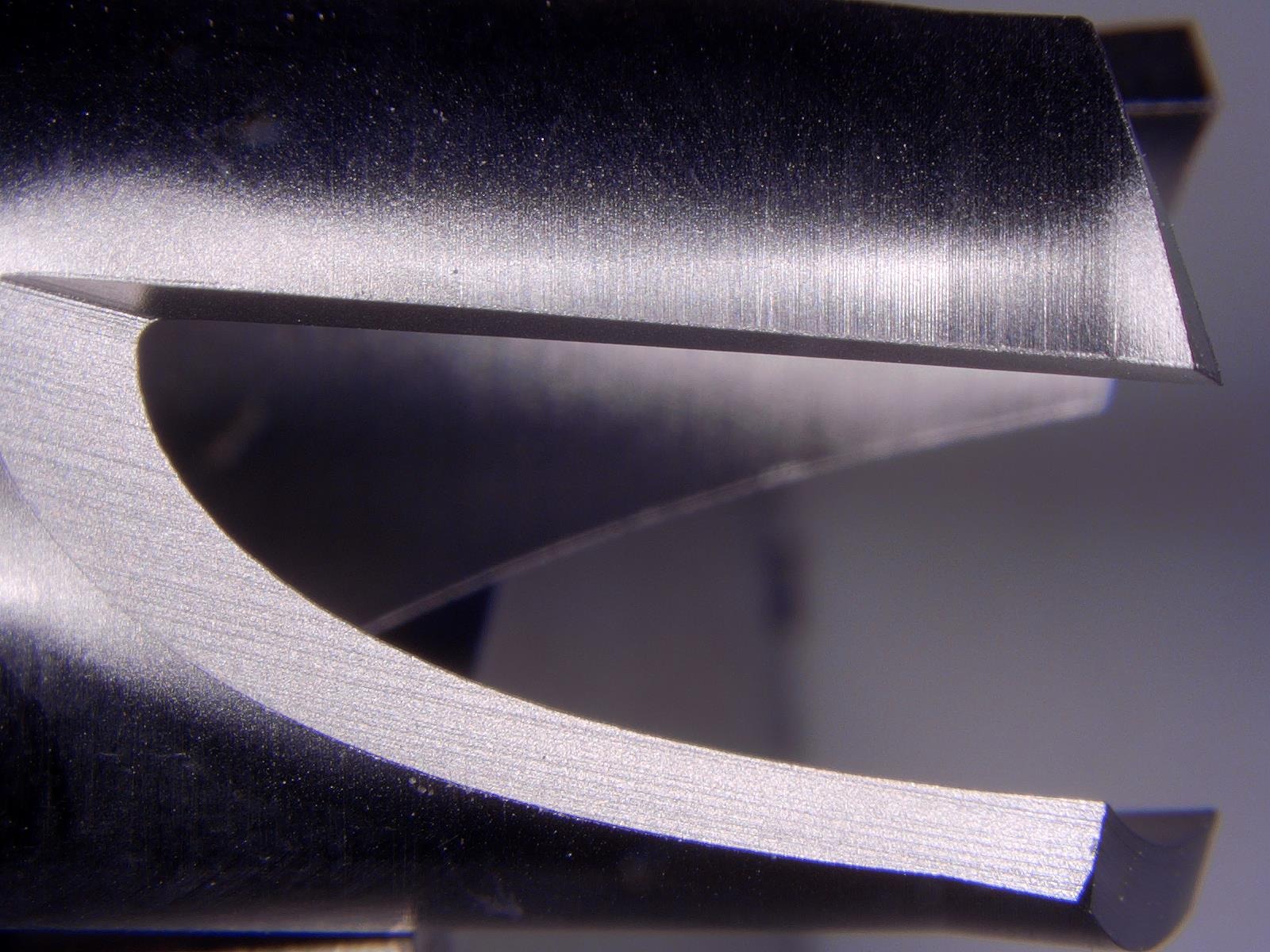

Cranial Perforator

What? Deburr blades for drilling cores out of a section in the skull

Why MicroBlasting? Removes burrs effectively without dulling the cutting edge.

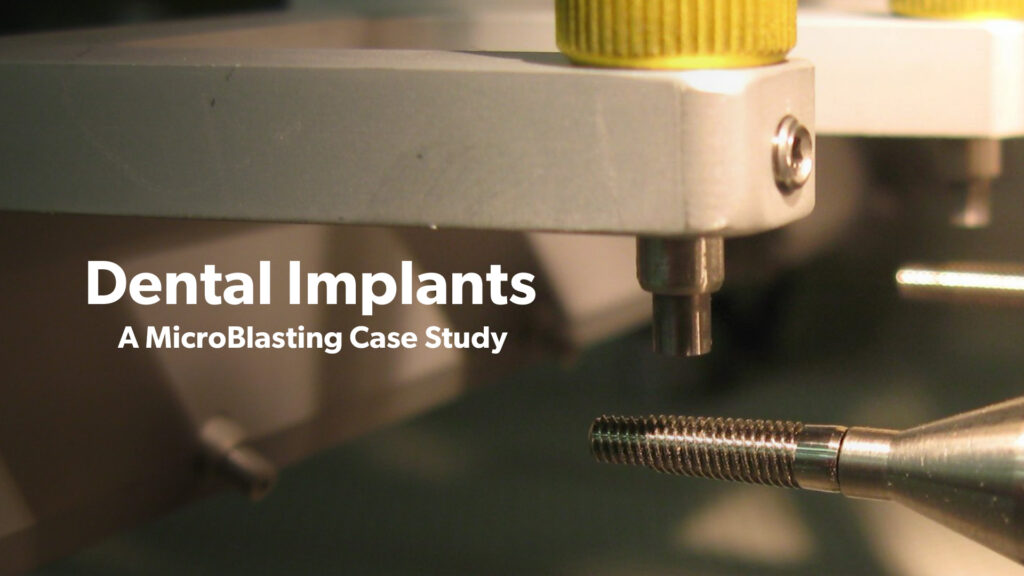

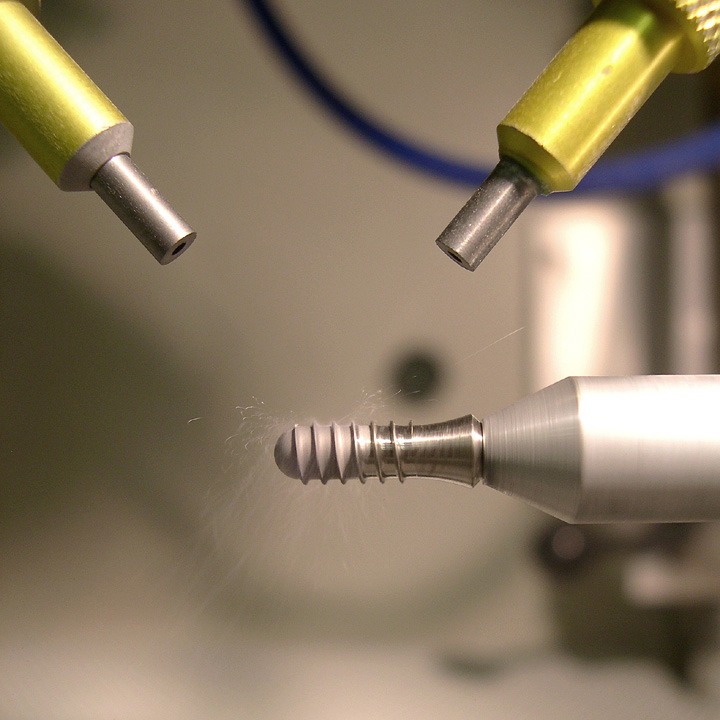

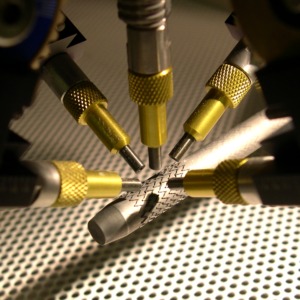

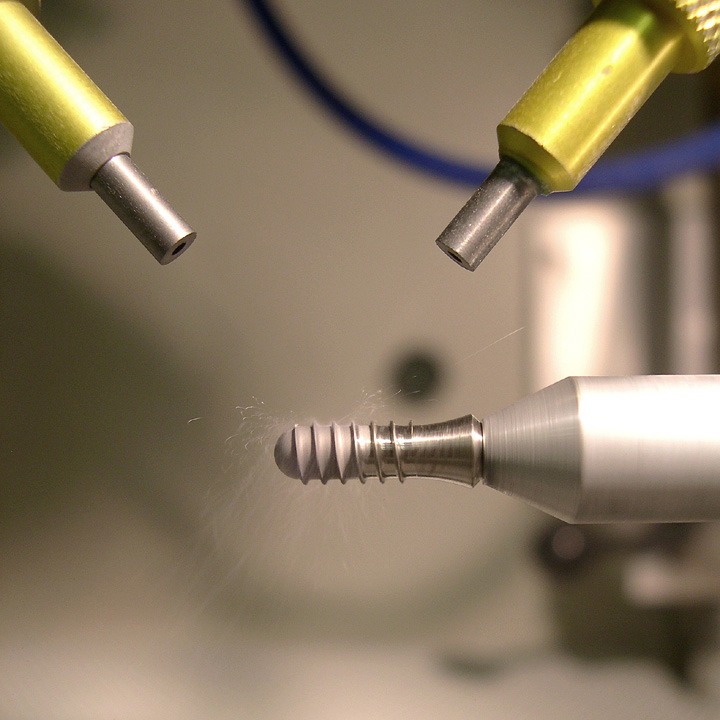

Dental Implants

What? – Create a textured surface optimized for osseointegration

Why MicroBlasting? – Achieve a consistent, specific Ra surface finish without reducing major diameter of the threads

Cochlear Implants

What? Deburr miniature components

Why MicroBlasting? Safely removes burrs without causing dimensional changes

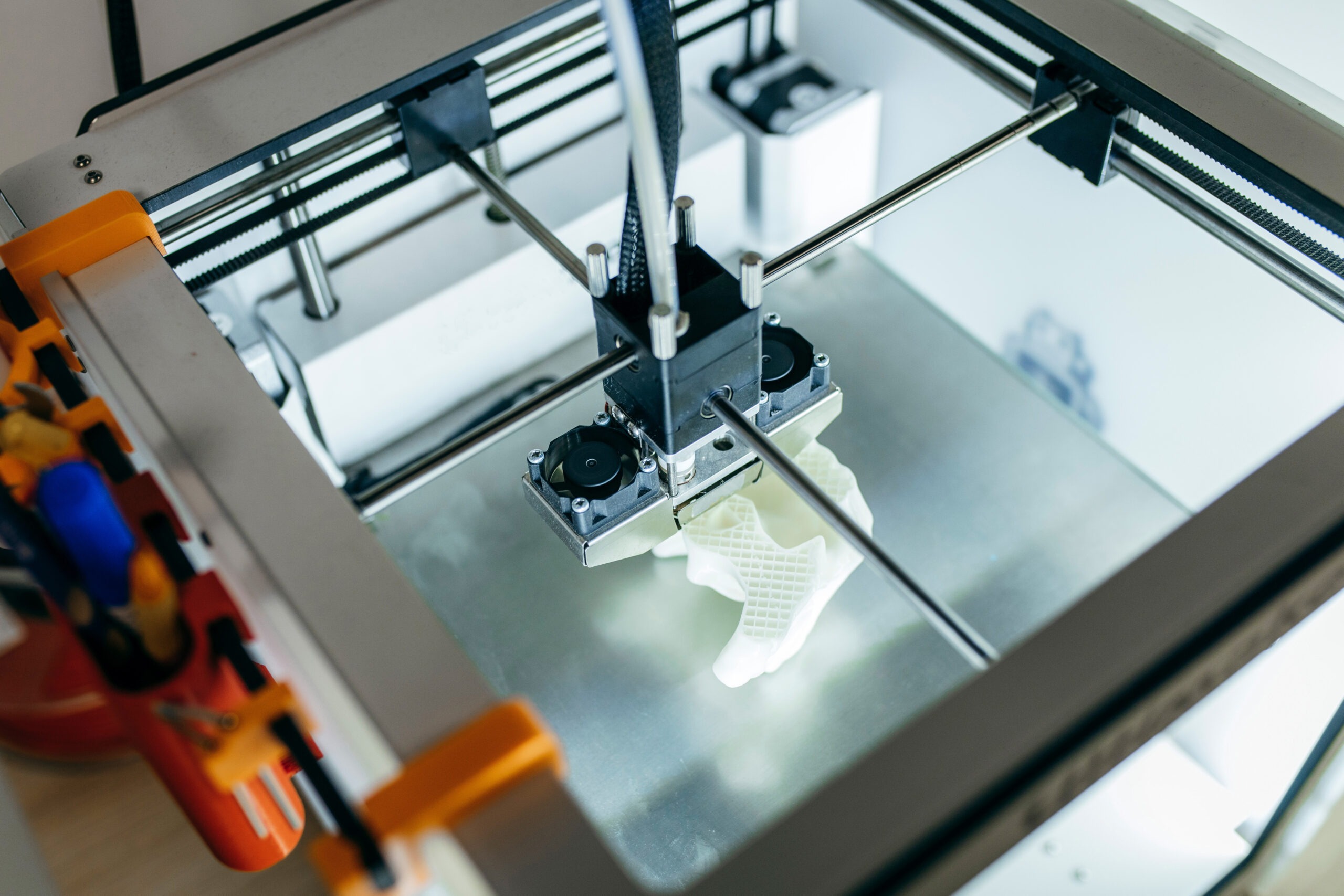

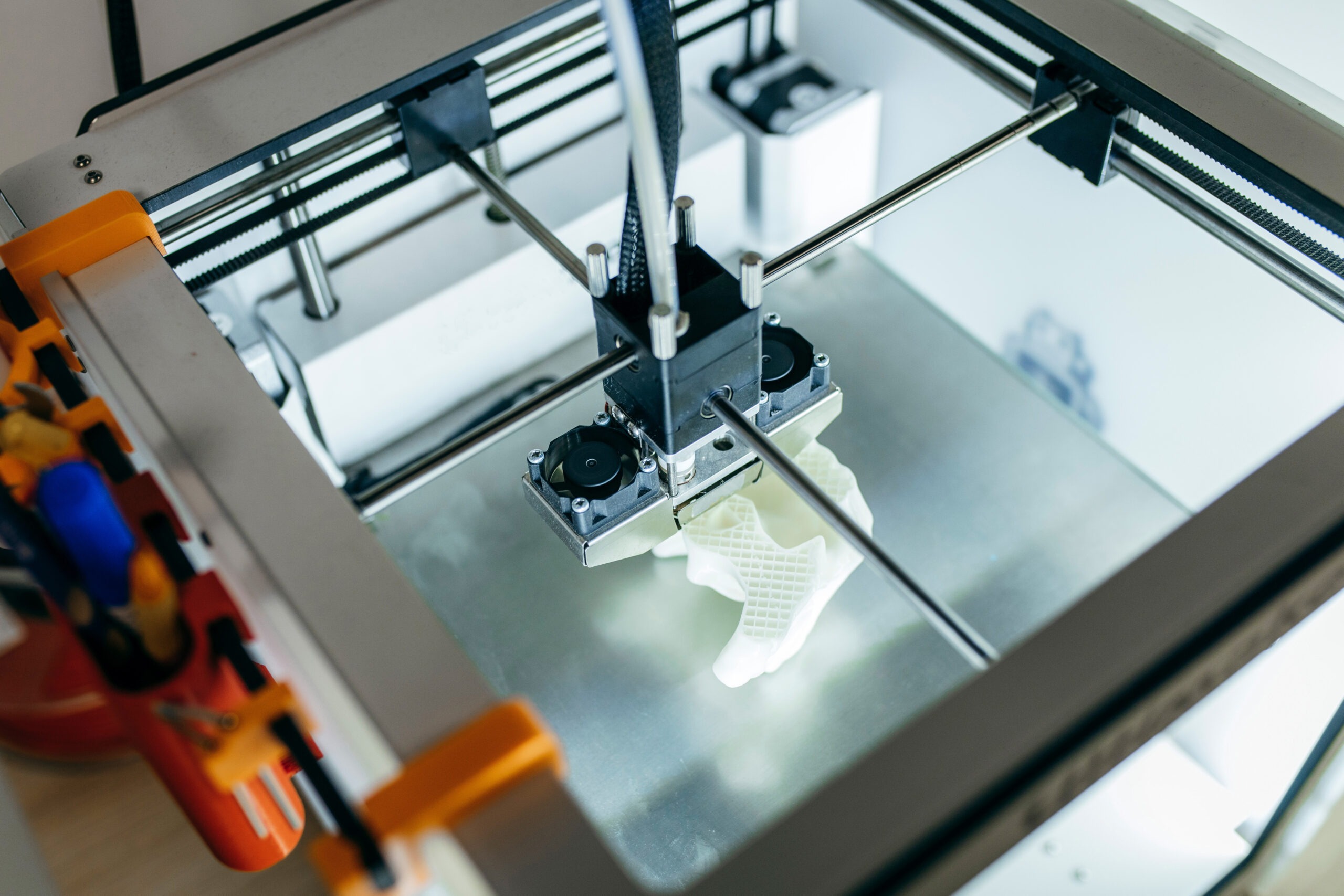

3D printed ear parts

What? Strip semi-integrated material from the surface of 3D printed components; create a uniform cosmetic finish

Why MicroBlasting? Removes material without causing dimensional changes

Endoscope

What? Texture for radiopacity

Why MicroBlasting? Efficiently applies a uniform surface finish

Mitral heart valve

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

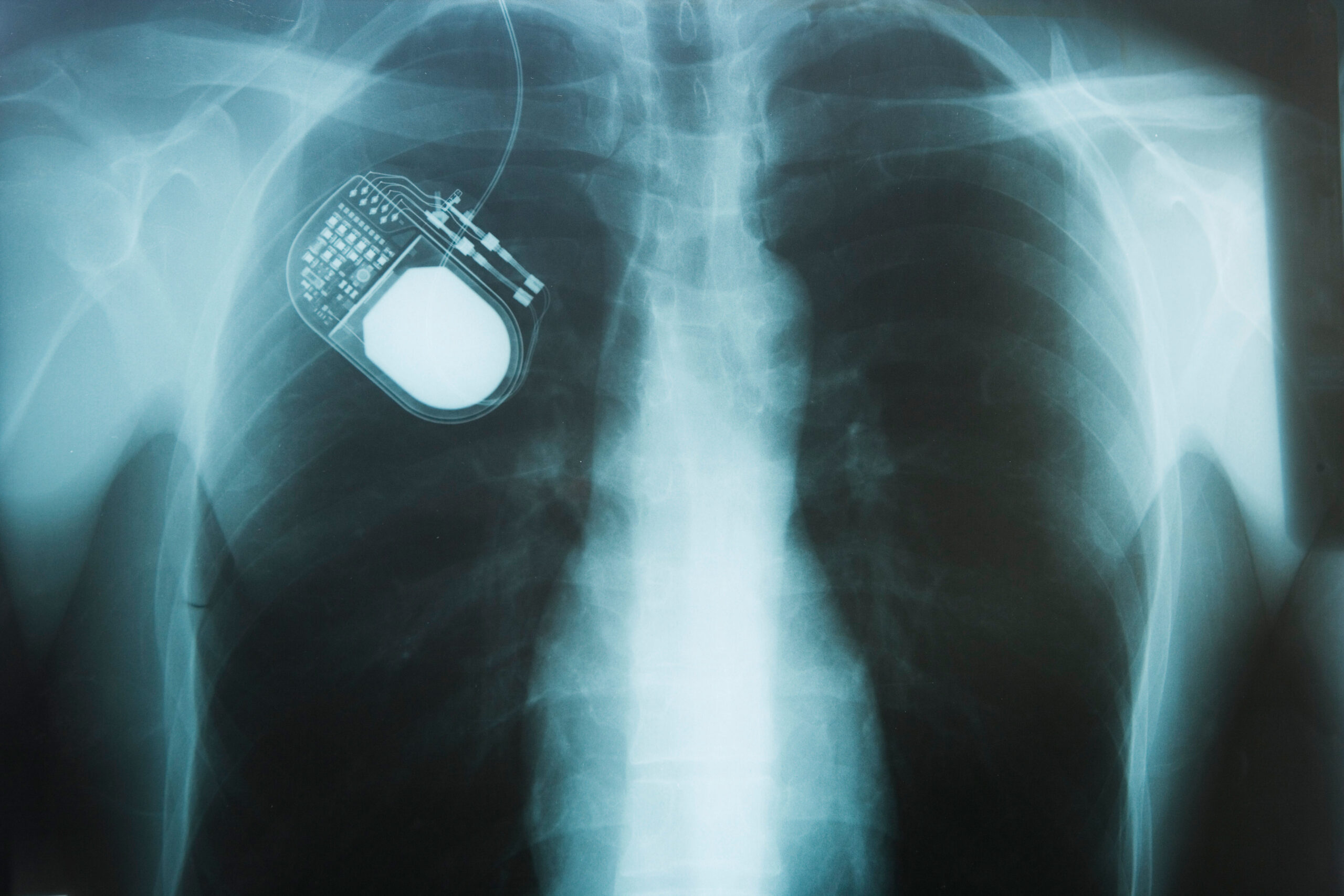

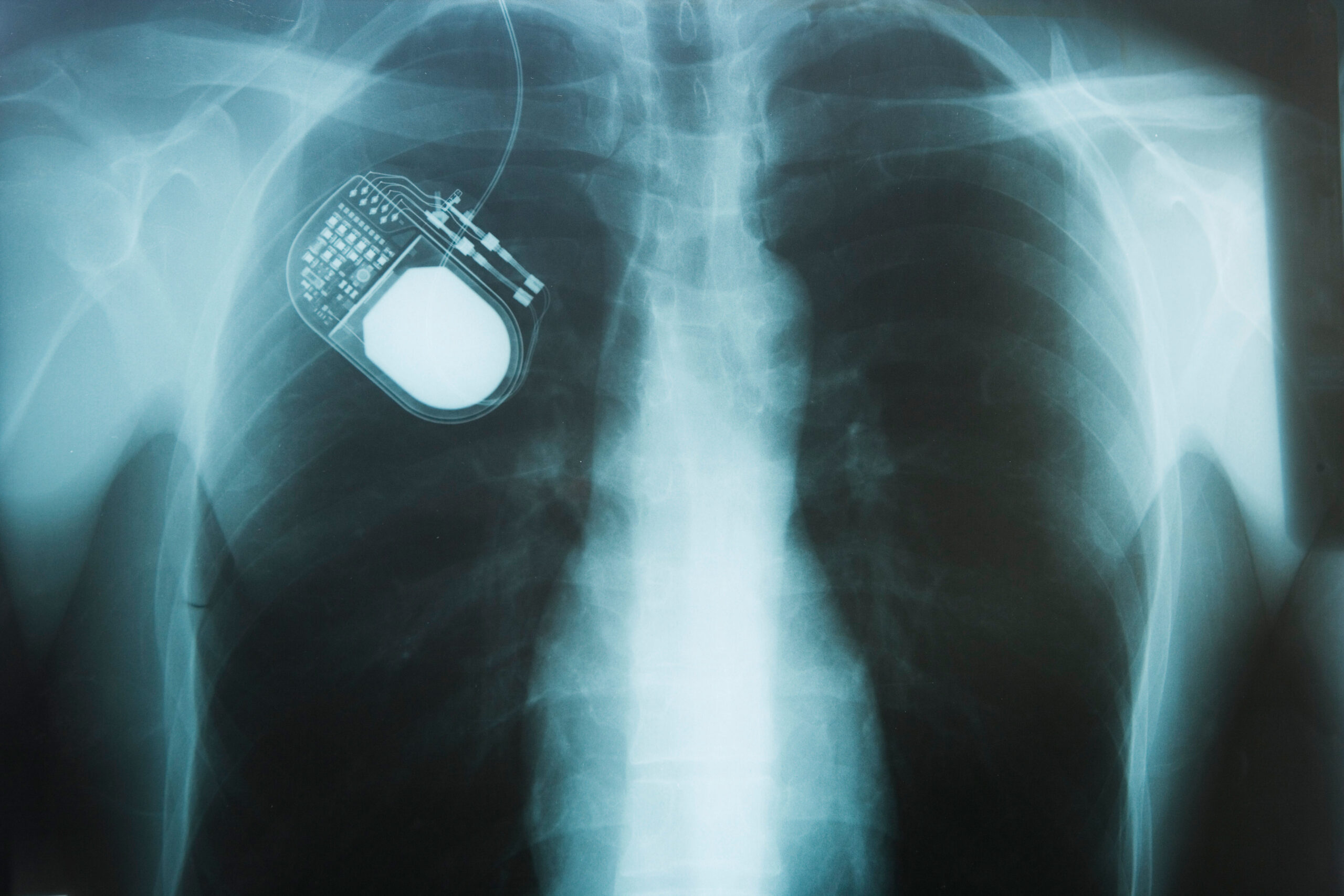

Pacemakers

What? Remove cosmetic defects, excess epoxy between the header and the can, metalization on pacemaker connectors, and silicone on pacing leads.

Why MicroBlasting? Provides an effective finishing solution for several different challenges in one tool.

Prosthetic heart

What? Texture for bond adhesion; create surface finish prior to polishing

Why MicroBlasting? Consistently create a specific surface texture.

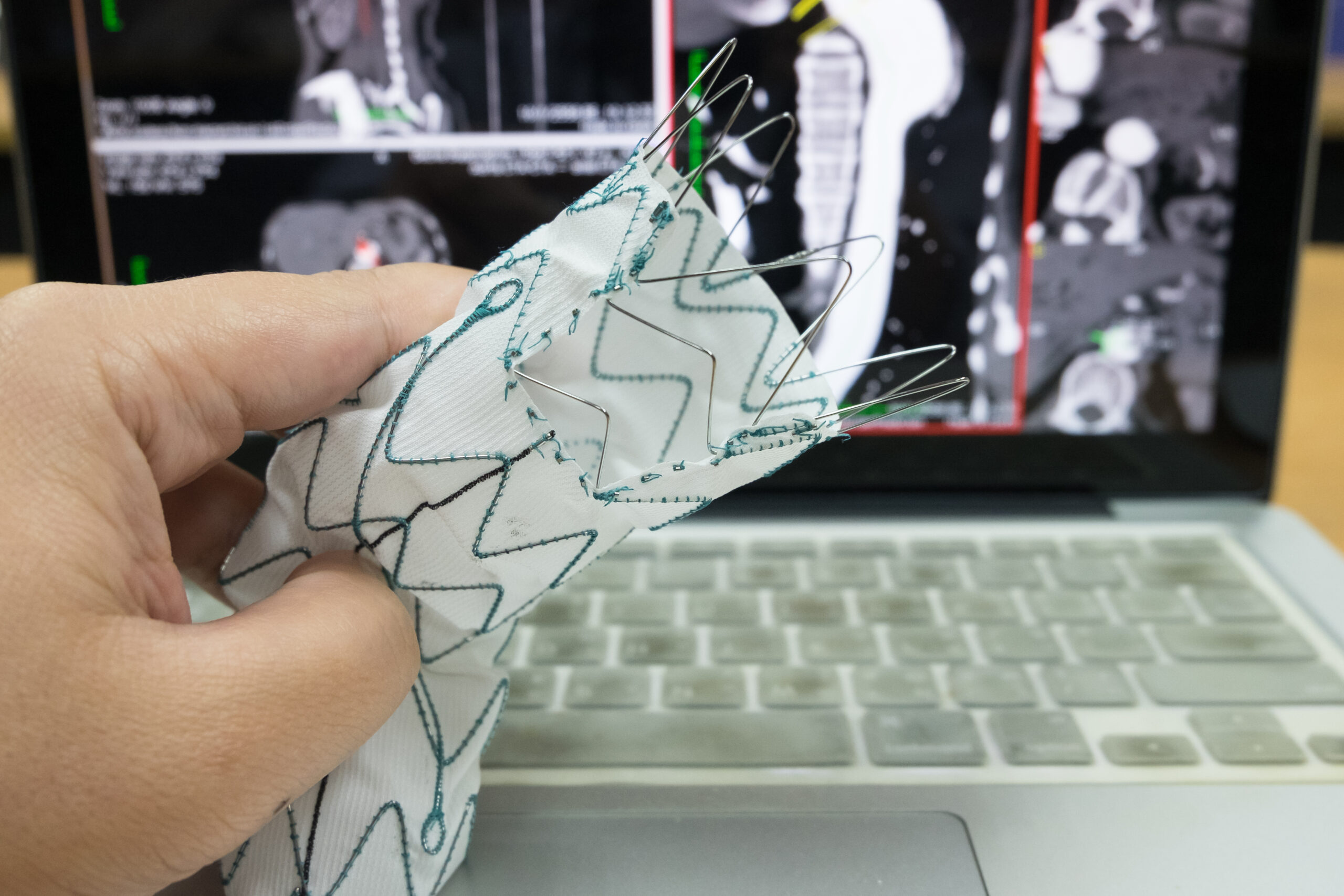

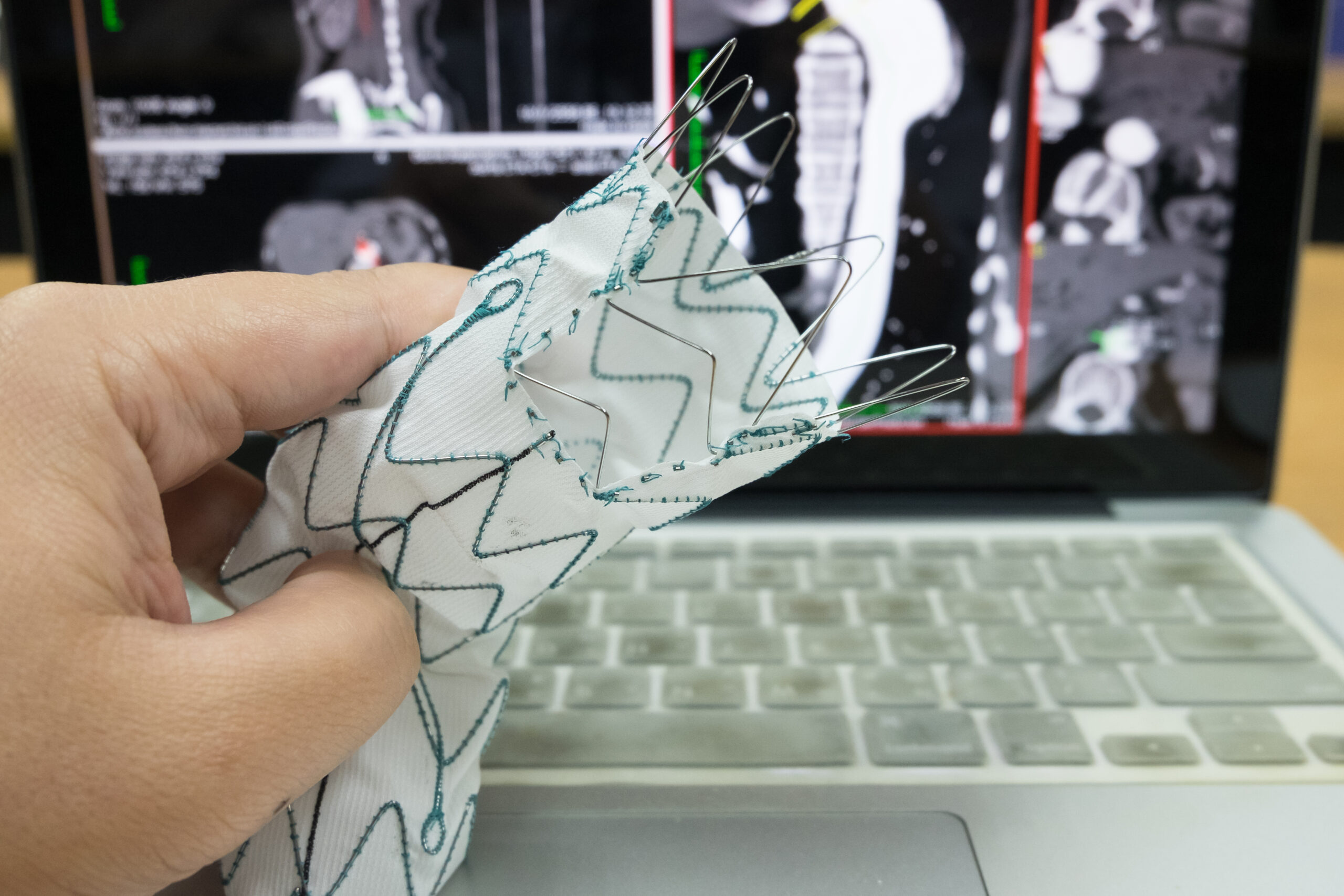

AAA device

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

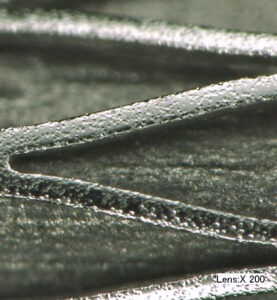

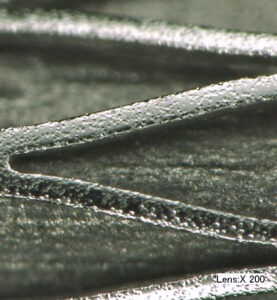

Drug eluting stents

What? Apply a peened surface finish to stainless or cobalt chrome stent

Why MicroBlasting? Control over pocket created is used to meter the medication into the surrounding vessel tissue.

Mechanical heart valve

What? Graphite removal from pyrolytic carbon

Why MicroBlasting? Effectively removes graphite without damaging the carbon.

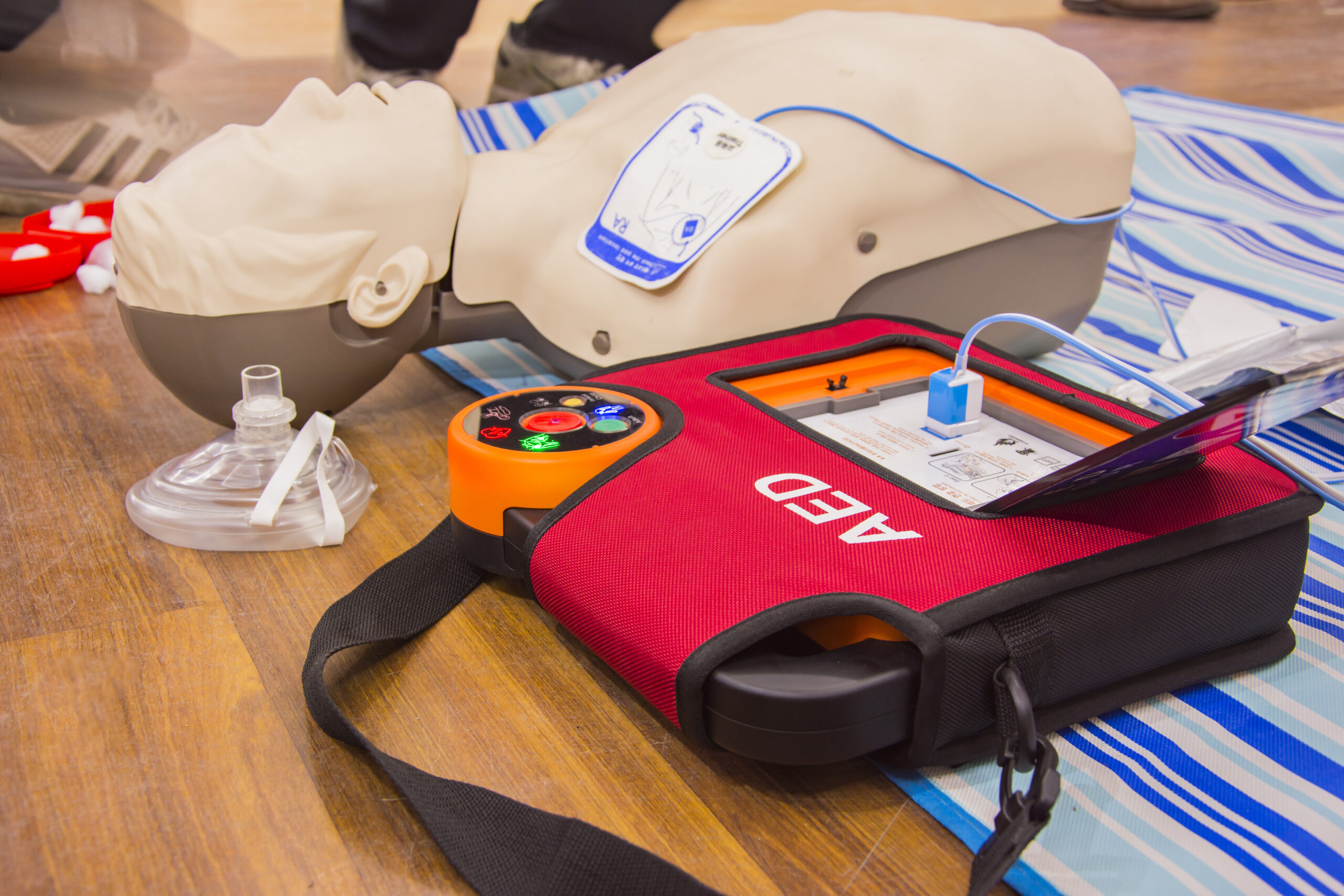

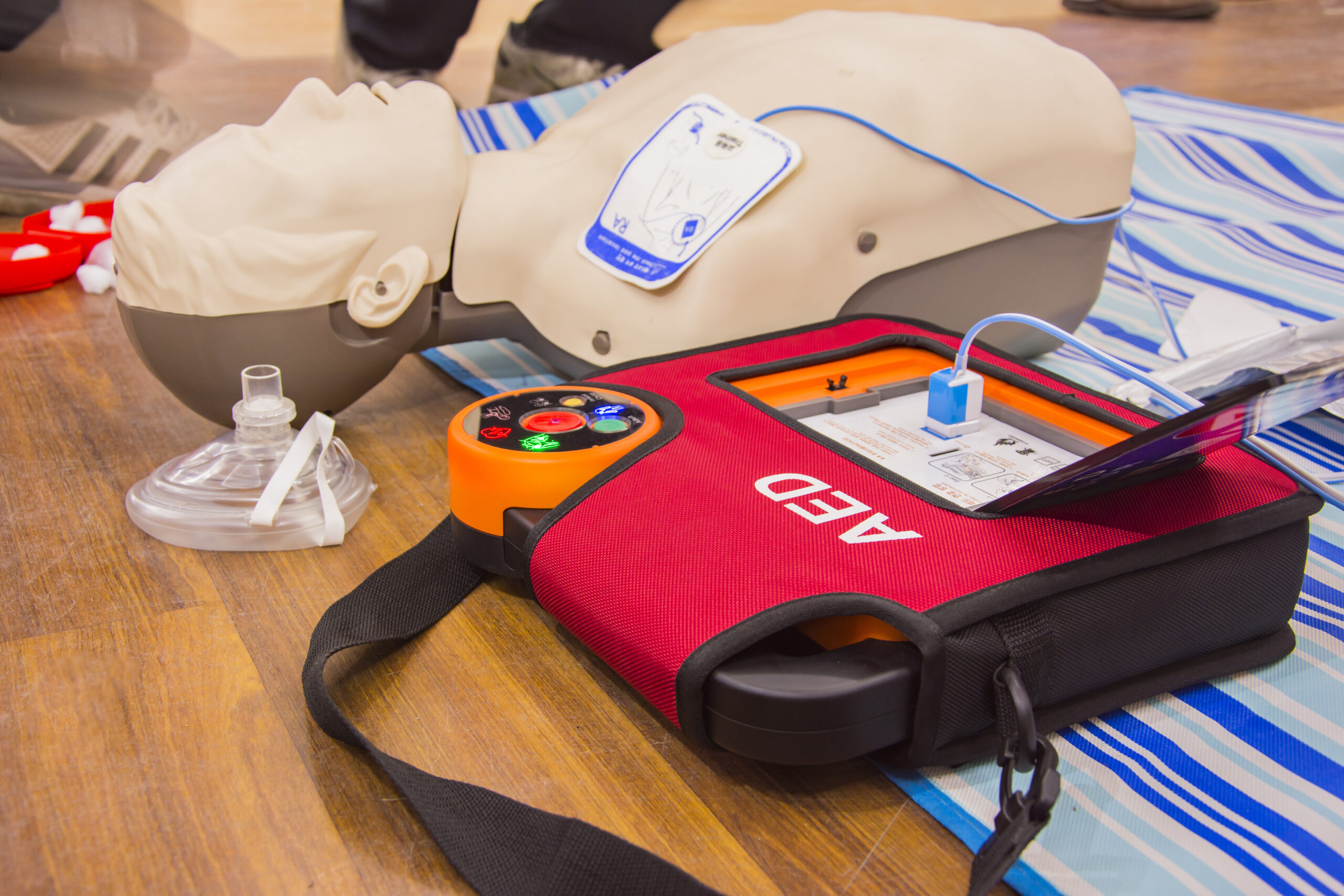

AED (external defibrillator)

What? Selective conformal coating removal on circuit boards for testing and repair

Why MicroBlasting? Works effectively to selectively remove a variety of coatings

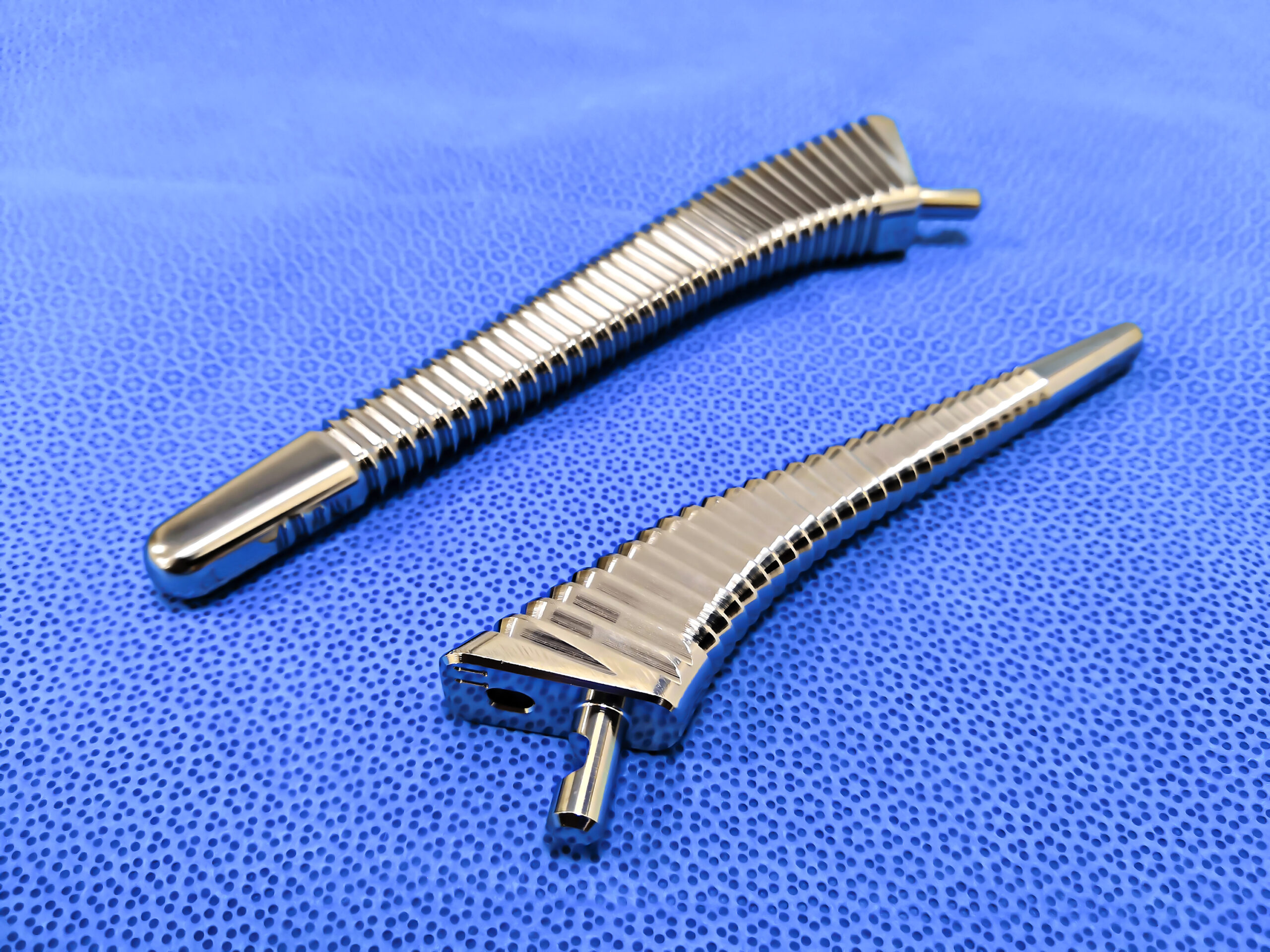

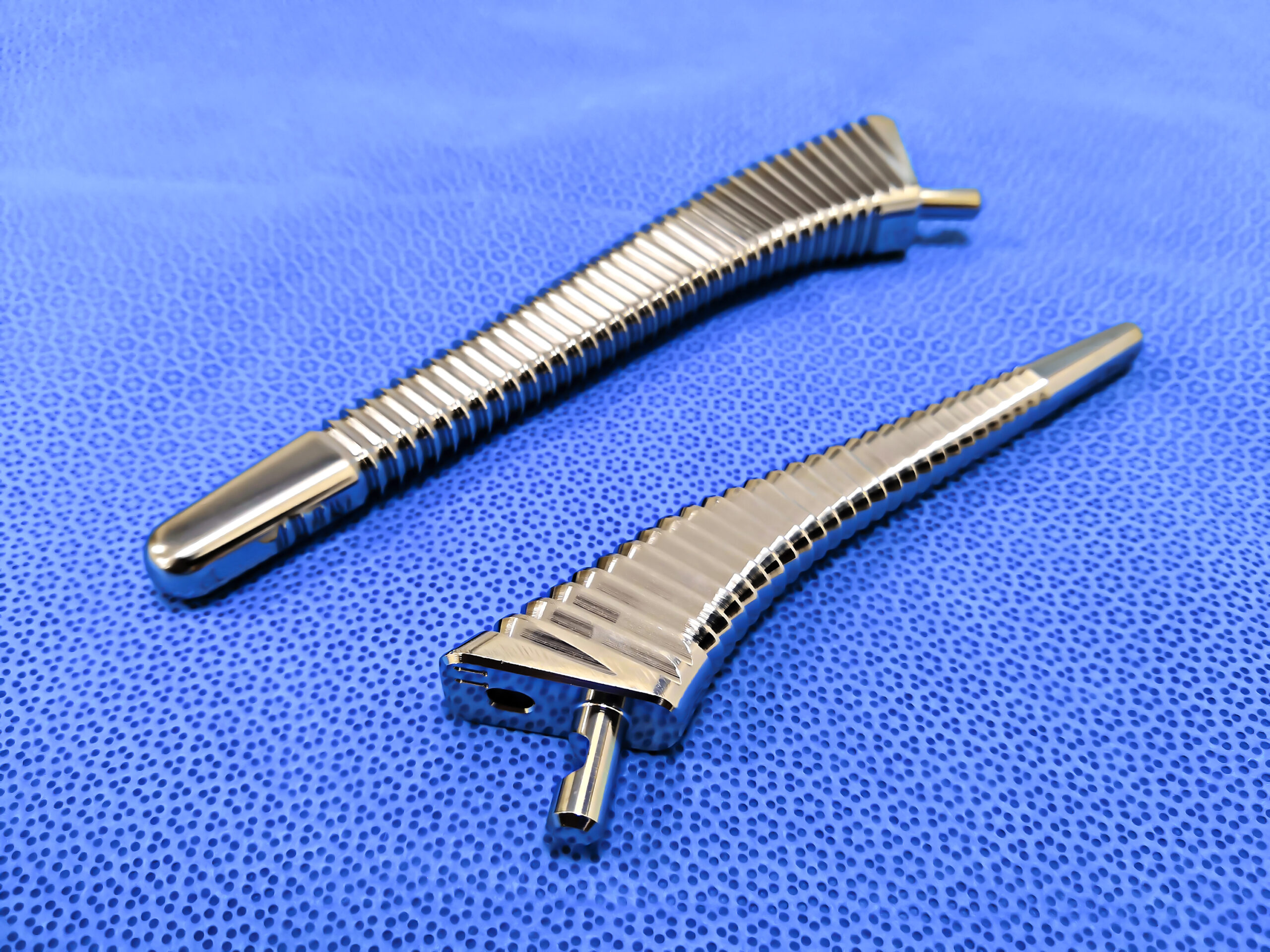

Titanium alloy spinal implants

What? Texture surface and deburr machined or 3D printed parts

Why MicroBlasting? Impart a specific Ra textured finish for improved bone in-growth and remove burrs efficiently without causing dimensional changes.

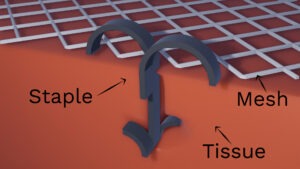

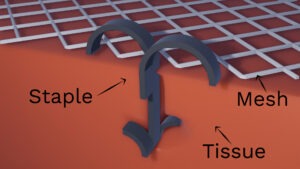

Hernia staples

What? Remove stress concentrations generated from shape setting nitinol; remove oxide and laser pulse marks

Why MicroBlasting? Removing stress concentrations and residues creates a uniform finish that improves the electropolish finish.

Neuro stimulation device – pain management and bladder control

What? Remove cosmetic defects, excess epoxy between the header and the can, metalization on connectors, and silicone on leads.

Why MicroBlasting? Provides an effective finishing solution for several different challenges in one tool.

Bone plates

What? Remove fine burrs left by machining process

Why MicroBlasting? Quickly removes these burrs without altering the surface finish or texture.

Wrist fixation device

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

Orthopedic devices

What? Texturing and surface finishing

Why MicroBlasting? Target locations for texturing where the implant needs to be cemented into existing bone; removes machining marks and other imperfections caused by the manufacturing process.

Peripheral stents

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

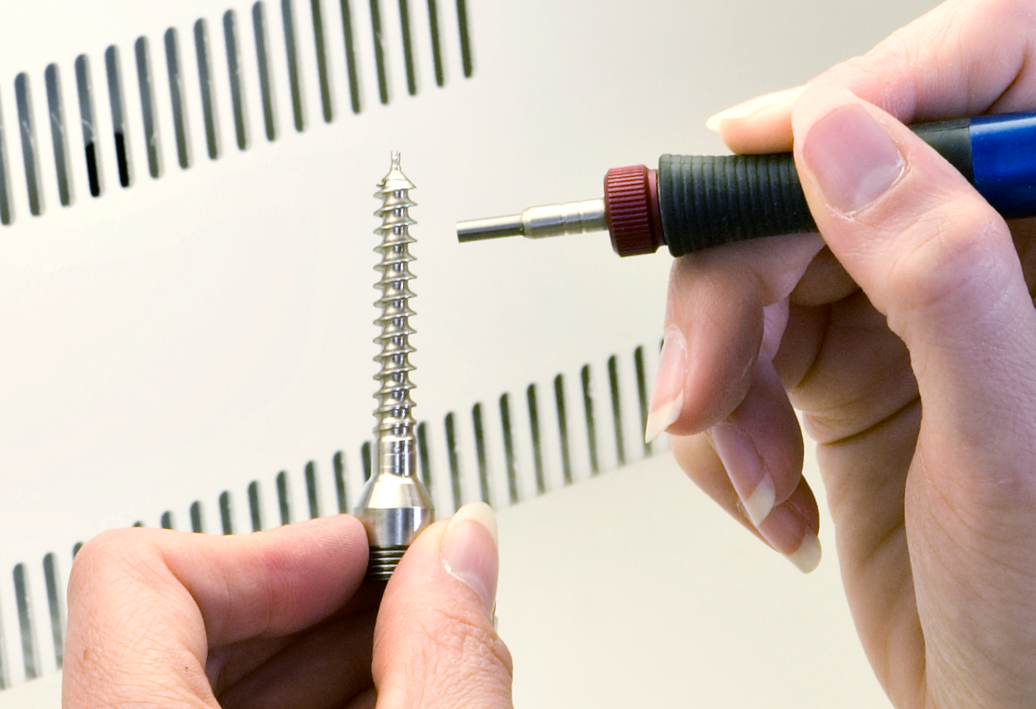

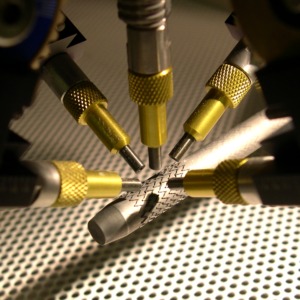

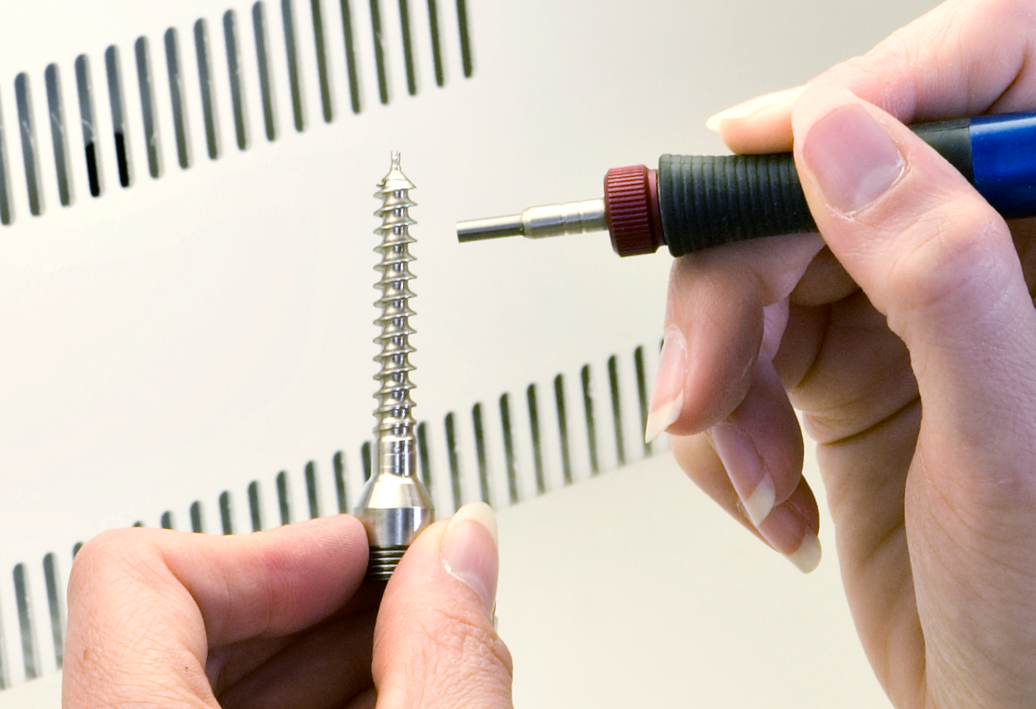

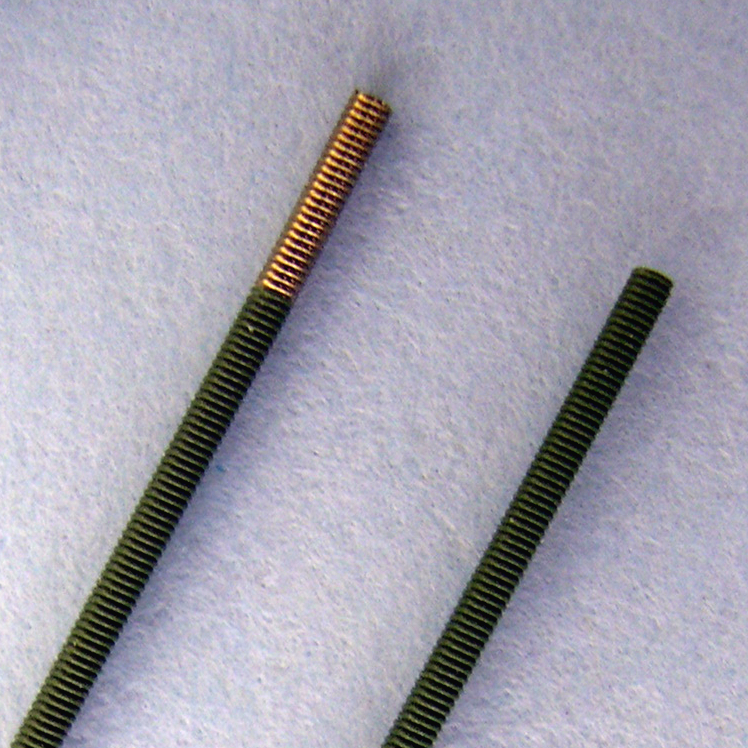

Bone screws

What? Burr removal on threads and socket; texturing screw head

Why MicroBlasting? Efficiently removes burrs without damaging or dulling the cutting edges. Texture to a sharp delineation without masking.

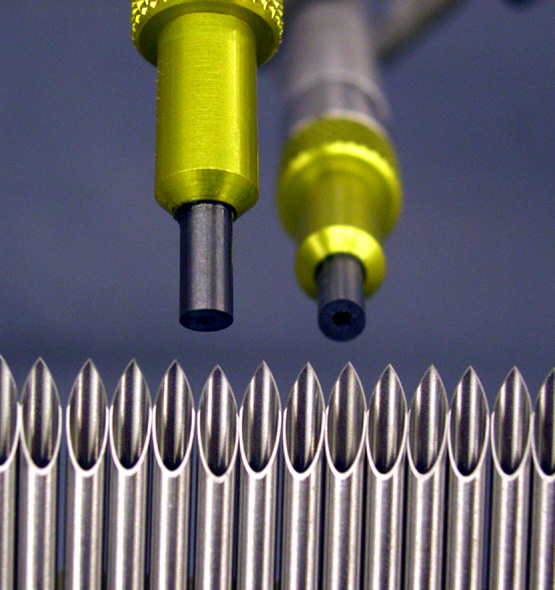

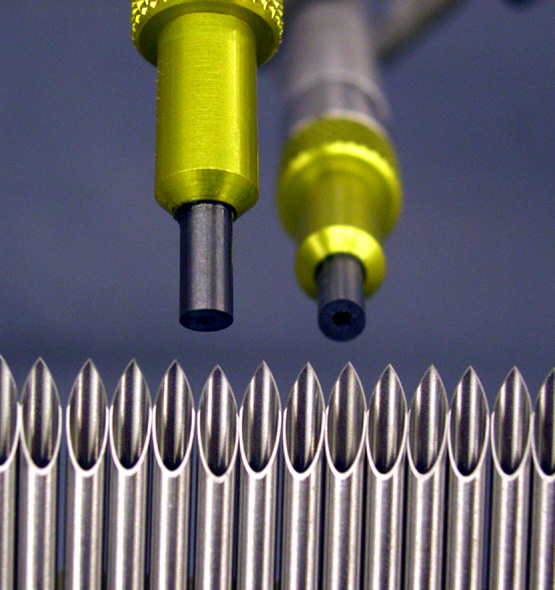

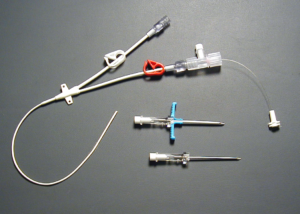

Cannula

What? Remove burr and dull cutting edge at heel; cut side ports holes; deburr side port slots; texture for overmolding bond adhesion

Why MicroBlasting? Ability to target selective areas effectively: targets heel without dulling needlepoint; texture to a sharp delineation without masking.

Suture needle

What? Apply a slight radius to the hook to reduce the risk of the suture being nicked during the procedure

Why MicroBlasting? Localized deburring without damaging the part or altering the finish

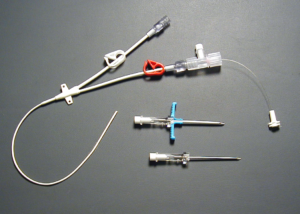

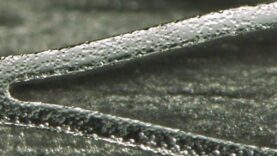

Guidewires/ Catheters

What? Remove heel burr

Why MicroBlasting? Target heel burr precisely without dulling the cutting tip

PEEK spinal implants

What? – Remove fine feather burrs

Why MicroBlasting? – Operators easily follow the contours of an implant to remove burrs quickly and safely without causing dimensional changes.

Cranial Perforator

What? Deburr blades for drilling cores out of a section in the skull

Why MicroBlasting? Removes burrs effectively without dulling the cutting edge.

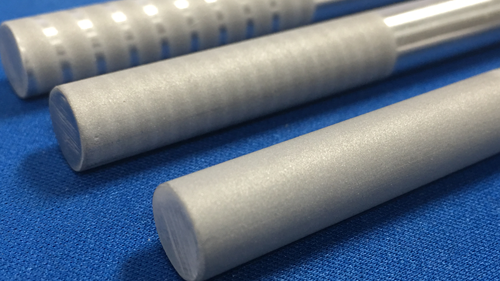

Dental Implants

What? – Create a textured surface optimized for osseointegration

Why MicroBlasting? – Achieve a consistent, specific Ra surface finish without reducing major diameter of the threads

Cochlear Implants

What? Deburr miniature components

Why MicroBlasting? Safely removes burrs without causing dimensional changes

3D printed ear parts

What? Strip semi-integrated material from the surface of 3D printed components; create a uniform cosmetic finish

Why MicroBlasting? Removes material without causing dimensional changes

Endoscope

What? Texture for radiopacity

Why MicroBlasting? Efficiently applies a uniform surface finish

Mitral heart valve

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

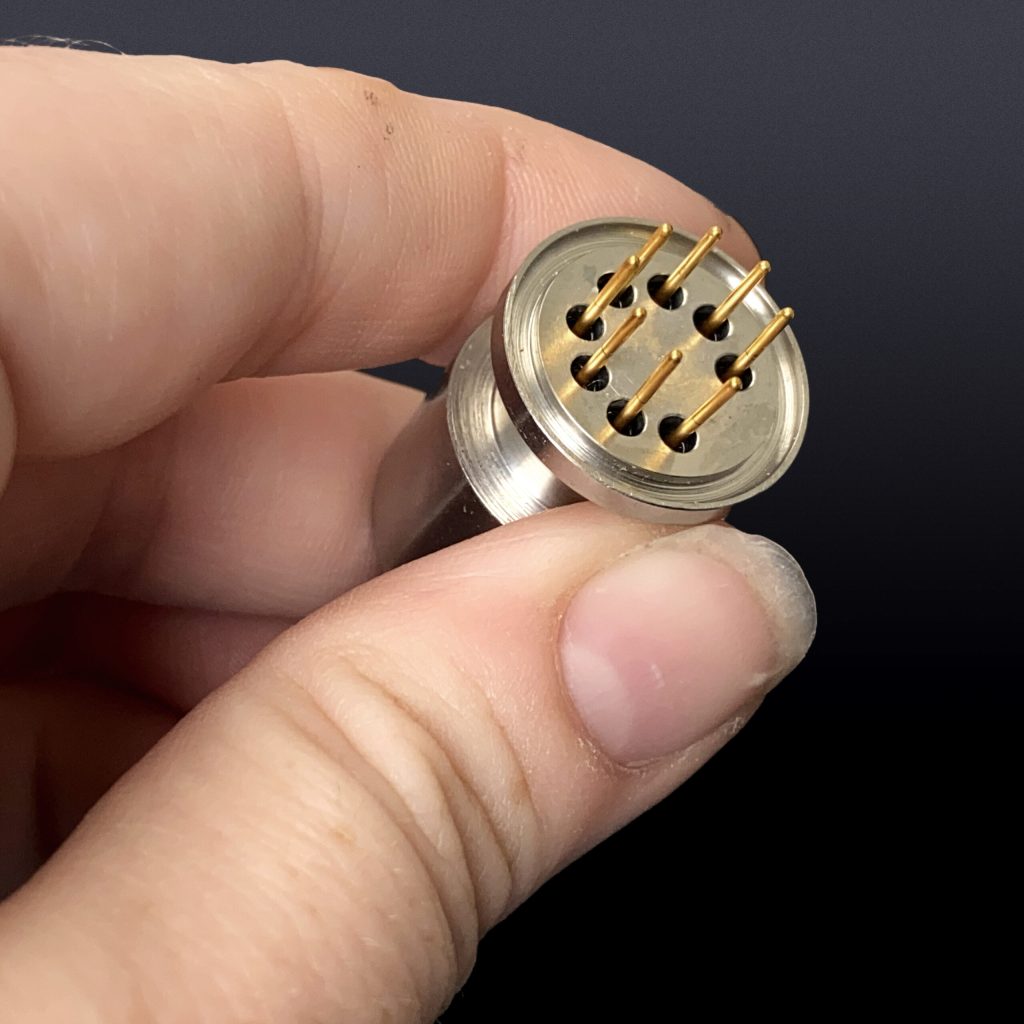

Pacemakers

What? Remove cosmetic defects, excess epoxy between the header and the can, metalization on pacemaker connectors, and silicone on pacing leads.

Why MicroBlasting? Provides an effective finishing solution for several different challenges in one tool.

Prosthetic heart

What? Texture for bond adhesion; create surface finish prior to polishing

Why MicroBlasting? Consistently create a specific surface texture.

AAA device

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

Drug eluting stents

What? Apply a peened surface finish to stainless or cobalt chrome stent

Why MicroBlasting? Control over pocket created is used to meter the medication into the surrounding vessel tissue.

Mechanical heart valve

What? Graphite removal from pyrolytic carbon

Why MicroBlasting? Effectively removes graphite without damaging the carbon.

AED (external defibrillator)

What? Selective conformal coating removal on circuit boards for testing and repair

Why MicroBlasting? Works effectively to selectively remove a variety of coatings

Titanium alloy spinal implants

What? Texture surface and deburr machined or 3D printed parts

Why MicroBlasting? Impart a specific Ra textured finish for improved bone in-growth and remove burrs efficiently without causing dimensional changes.

Hernia staples

What? Remove stress concentrations generated from shape setting nitinol; remove oxide and laser pulse marks

Why MicroBlasting? Removing stress concentrations and residues creates a uniform finish that improves the electropolish finish.

Neuro stimulation device – pain management and bladder control

What? Remove cosmetic defects, excess epoxy between the header and the can, metalization on connectors, and silicone on leads.

Why MicroBlasting? Provides an effective finishing solution for several different challenges in one tool.

Bone plates

What? Remove fine burrs left by machining process

Why MicroBlasting? Quickly removes these burrs without altering the surface finish or texture.

Wrist fixation device

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

Orthopedic devices

What? Texturing and surface finishing

Why MicroBlasting? Target locations for texturing where the implant needs to be cemented into existing bone; removes machining marks and other imperfections caused by the manufacturing process.

Peripheral stents

What? Remove oxides, laser pulse marks and heat affected zone (HAZ); Edge rounding at critical locations

Why MicroBlasting? Removes residues effectively and also works to reduce stress concentrations and micro-cracks that can propagate into fracture locations in a polished and implanted device; Also effective at consistent edge rounding within tight tolerances.

Bone screws

What? Burr removal on threads and socket; texturing screw head

Why MicroBlasting? Efficiently removes burrs without damaging or dulling the cutting edges. Texture to a sharp delineation without masking.

Cannula

What? Remove burr and dull cutting edge at heel; cut side ports holes; deburr side port slots; texture for overmolding bond adhesion

Why MicroBlasting? Ability to target selective areas effectively: targets heel without dulling needlepoint; texture to a sharp delineation without masking.

Suture needle

What? Apply a slight radius to the hook to reduce the risk of the suture being nicked during the procedure

Why MicroBlasting? Localized deburring without damaging the part or altering the finish

Guidewires/ Catheters

What? Remove heel burr

Why MicroBlasting? Target heel burr precisely without dulling the cutting tip

55+

years

We have over 55 years of experience in perfecting MicroBlasting technologies and partnering with clients to help them solve their unique manufacturing challenges.

1000+

customers serving the medical device industry

From job shops to top tier medical device manufacturers, we have worked with a wide range of medical device designers and manufacturers to improve their processes. Whether you’re looking to solve a problem in-house or provide a solution to your contract manufacturing partner, we’re ready to work with you.

175+

automated systems in 20+ countries worldwide

From North America to Europe to Asia and on to Africa and South America, Comco has traversed the globe to install custom automated microblasting solutions to far reaching customers.

Your Partner for Industrial Engineering Solutions

We’ll work closely with you by applying our engineering skills to your problem, providing the process with our technologies, and sharing our accumulated expertise to develop solutions that are efficient and cost effective.

-

Applied Engineering with a Deep Understanding of Medical Parts

Engineering is at the core of Comco. Our engineers have a background in the medical, aerospace, and semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

-

Providing the process at no additional cost to you

Let us prove how a custom MicroBlasting process would work for you while sharing our engineering expertise up front, without charge.rn

-

Sharing our skills & knowledge throughout our partnership

We’ll share our engineering skills and knowledge at every step of our partnership. Advanced technical support continues beyond your initial purchase of our MicroBlasting systems, and we also offer assistance with new applications as they arise.rn

What can be achieved with MicroBlasting?

Whether it’s deburring bone screws, needle or implant, removing dross from laser cut stents or imparting an aesthetic surface finish on pacemaker cans, MicroBlasting technology has a wide range of uses in the medical device industry.

Four Processes, Countless Applications

Dental Implants

Bone Screws

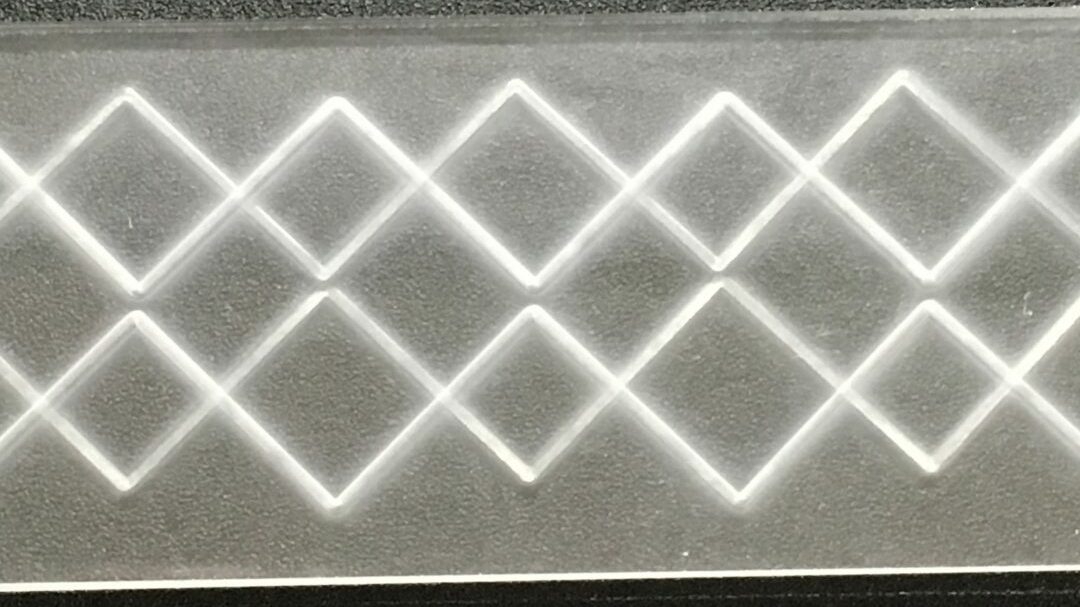

Surface Texturing on the Blog

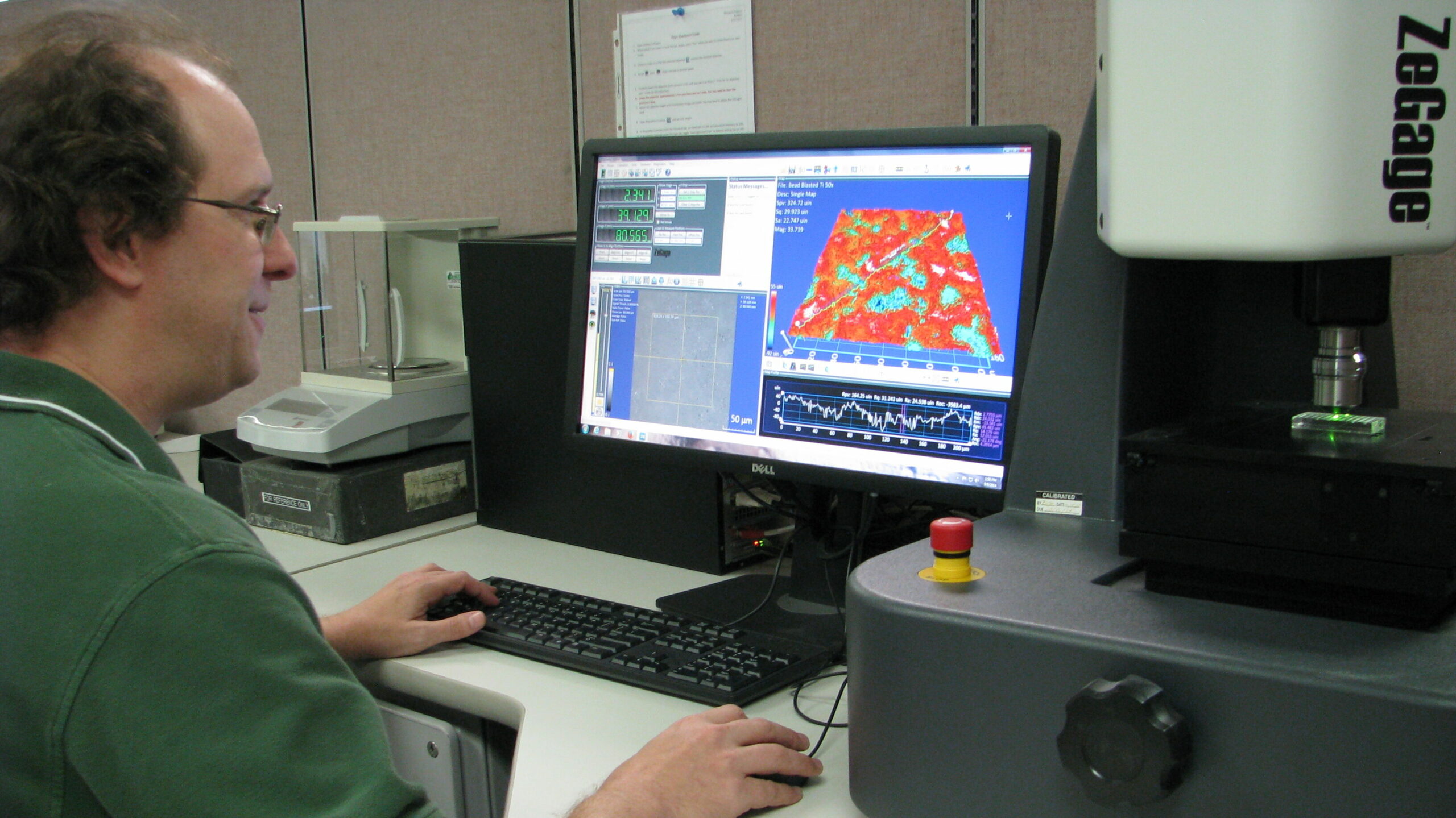

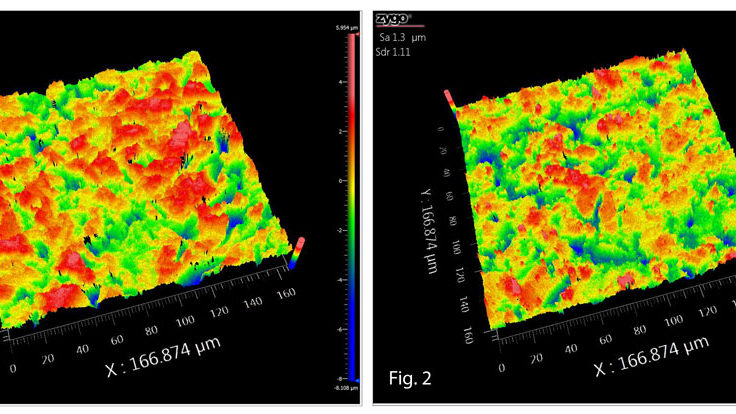

Need a consistent and repeatable surface finish?

Not getting a consistent surface finish? Change your surface finish spec to include three measurable details. Learn what your spec may be missing, and why these three points yield repeatable returns.

Read More

How to calculate stepover and get a uniform surface finish

Avoid uneven results while texturing or etching parts. Learn what stepover percentage works in most applications. Incl. stepover calculator.

Read More

Need to Improve Bond Strength?

Ra or Sa alone cannot predict bond strength in all applications. Epoxied surfaces, in particular, require a more comprehensive specification. To get repeatable results in pull and peel tests, incorporate a high developed surface ratio (Sdr) and require full coverage.

Read MoreNitinol Stents

Pacemakers

Coating Removal on the Blog

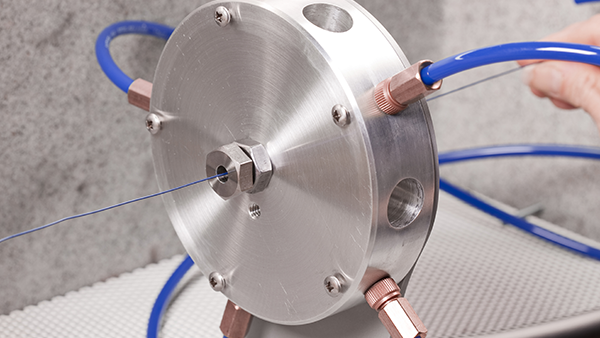

Wire stripping? Get uniform removal + sharp delineation with the ring nozzle

A selection of micro-lessons from our blog that focus on advances in MicroBlasting tools and technology. Includes design and development of new equipment and accessories to help you blast better.

Read More

Conformal Coating Removal

Wheat starch is a very soft abrasive, but it has just enough abrading power to gently lift really thin layers of conformal coating without risk to an underlying solder mask or circuit board. Learn why you may want to consider it, and learn why MicroBlasting, in general, is a great method for conformal coating removal.

Read MorePEEK Spinal Implants

Bone Screws

Precision Deburring on the Blog

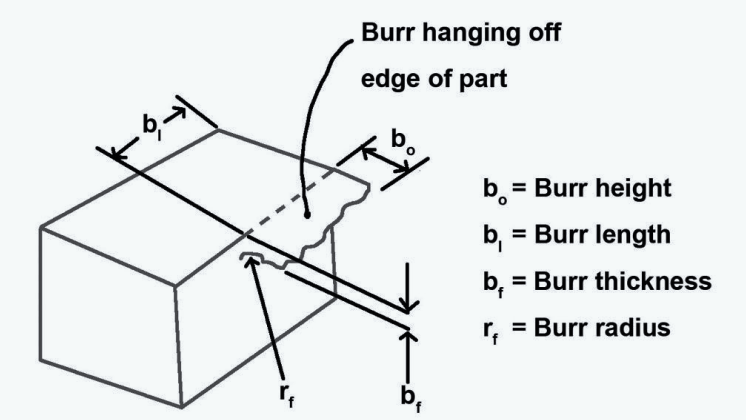

5 Factors that Lead to Successful Deburring

In this quick video lesson, we break down the 5 factors that impact most deburring applications. When you’re done, you’ll know how to deburr…better!

Read More

Six Quick Deburring Case Studies

Learn what abrasive, nozzle and blast pressure are used to precisely remove burrs and refine surfaces on these small, intricate parts. Includes: metal gears, PEEK spinal implants, electronic packages, stainless steel valve components, aluminum fixtures and titanium components.

Read More

The Missing Measurment of Deburring

Are old burrs suddenly reappearing? Are burrs popping up in a new location on your part? Is a once-reliable deburring method starting to fail? Chances are, you’re missing a measurement. Manufacturing expert, LaRoux Gillespie, shares the deburring measurements often missed that lead to recurring problems and new burr formations.

Read MoreMechanical Heart Valves

MicroFluidics

Abrasive Jet Machining on the Blog

Edge rounding on Nitinol implants

Aluminum oxide has long been the go-to abrasive for cleaning stents, valves, and other Nitinol implants before electropolishing. But recently, selective edge-rounding entered the application, and aluminum oxide was not enough. This month, we look at how glass bead took a radius from 2 microns to 24 microns.

Read more

How to reliably create features to

A single pass of the focused abrasive stream from a MicroBlaster can uniformly remove 5 µin (0.127 microns) or less of material depending on the substrate, abrasive, and blast parameters. Given this level of precise and controllable erosion, you simply need to know how to fine-tune the process to suit your application.

Read more5 variables for abrasive jet machining

Using MicroBlasting to cut or etch a part (a process also known as controlled erosion) is a great method to machine many precision parts, from drilling holes in ceramic substrates to cutting slots in fragile silicon and glass wafers.

Read more

Materials: What you’re working with

MicroBlasting is an effective process for a variety of materials and compositions. Click below to view and search materials we often work with that are used by the medical industry.

Browse Materials

Materials We’ve Worked With

MicroBlasting is used on a variety of materials and compositions, thanks in part to the wide range of abrasive media available. We often work with the following materials used by the medical industry. Can’t find what you’re looking for? Contact us and we’ll let you know how your material(s) can be used with our MicroBlasting technologies.

Aluminum

Bronze

Copper

Ceramic

Glass

Graphite

Inconel

Kovar

Nitinol

Polypropylene

PEEK

PTFE

Silicon

Stainless Steel

Titanium

Brass

A Complete MicroBlasting Solution

Benefits of the Manual System

Comfortable

Ergonomic design reduces operator fatigue

Versatile

Flows a wide range of media

Consistent

Unique patented modulated abrasive feed

User Friendly

Easy to set-up and easy to maintain

Mobile

Casters allow for adaptive cell environments.rn

Clean and Quiet

Hepa filtration and customized fan box improves operation. rn

Cost-Effective

Our best deal for a turnkey solution

Benefits of the Automated System

Customizable

Offers a range of workholding and blast head options

Scalable

Designed to grow from manual to fully automatic

User friendly

Intuitive user interface for programming and operation

Turnkey

Delivered production ready

Peace of mind

Fully documented and supported

Consistent

Unique patented modulated abrasive feed

Robust

Stable in Full Production

Your Privacy & Security Are Our Priority

-

Our Commitment to Privacy

We are committed to protecting our clients. That’s why we take your highly specialized, confidential projects seriously.

-

Trusted Partners

Great customer relationships begin with trust. We are dedicated to protecting our clients’ confidential R&D sample parts and data.rn

-

Learn More

Contact us to learn more about how we follow the highest standards to protect your business data.

TRY OUR PROCESS

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a Demo