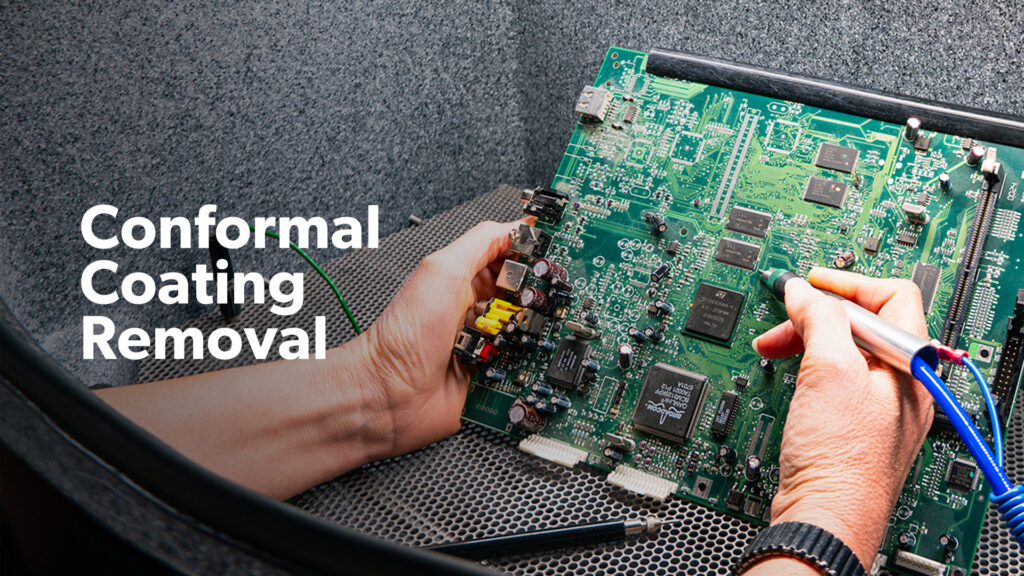

Coating

Removal with MicroBlasting

Perform delicate cleaning without damage to the underlying part. Comco’s MicroBlasting equipment can be used to strip coatings, remove residues, clean hot runner nozzles, and more.

Our process is effective, streamlined, and safe, reducing or eliminating the need for harsh chemicals or mechanical scraping that can damage your parts.

Unfamiliar

with

coating

removal?

Metalization on Ceramics

Remove metalization on ceramic components to improve electrical isolation.

Turbine Blades

Refurbish either land-based gas or jet-engine turbines by removing the protective oxide layer.

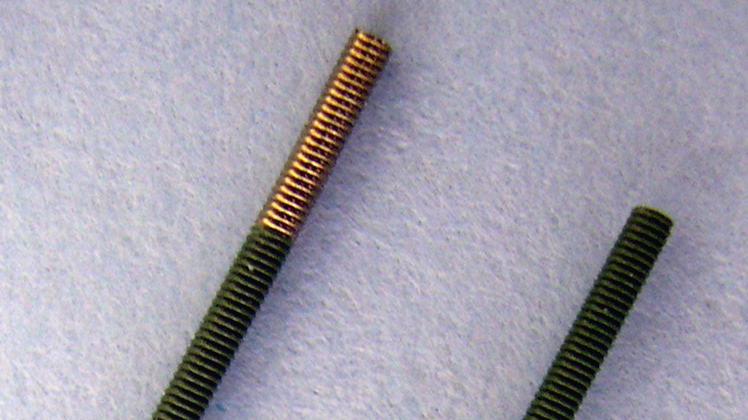

Nitinol stents

Remove surface defects without compromising the integrity of the delicate underlying material.

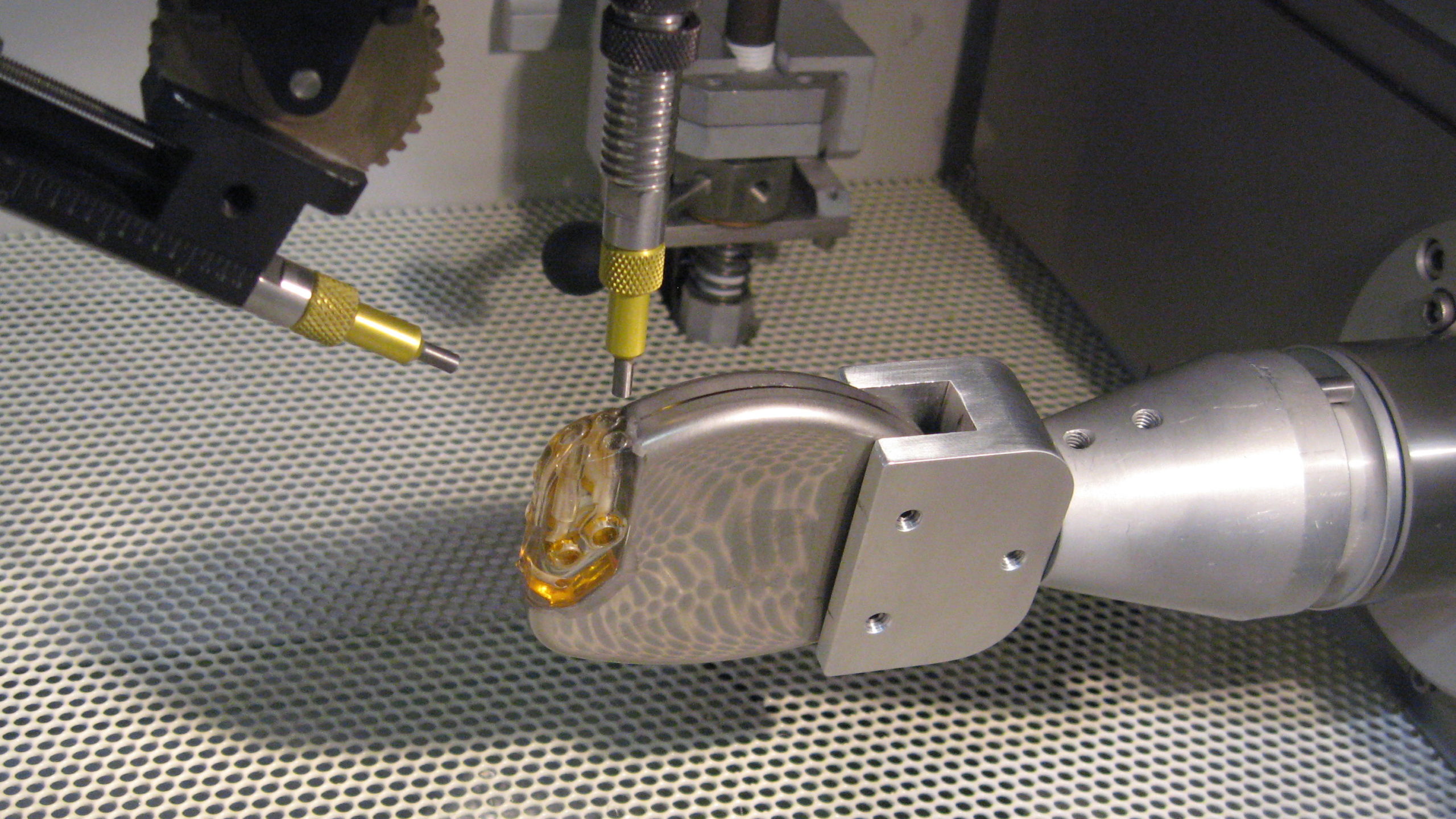

Pacemaker Headers

Remove excess encapsulation that seeps out from the header during installation.

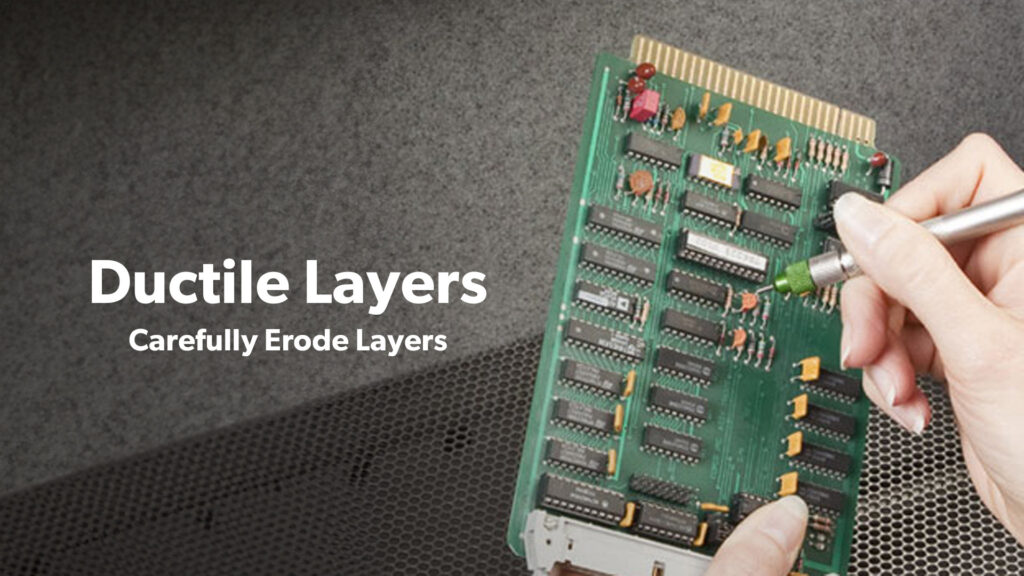

Brittle vs. Ductile

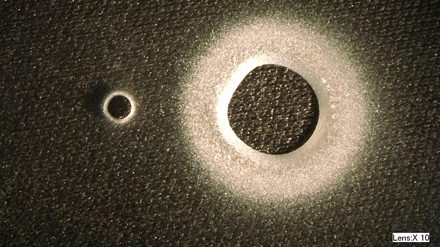

The selective cleaning process uses the abrasive qualities of MicroBlasting to carefully erode layers of unwanted material from a base substrate. The process takes advantage of the different physical properties of the two layers. Brittle materials can be removed from soft ductile layers, or soft ductile layers can be removed from brittle layers.

Read more

Spot Size

How far should I hold the nozzle from the part? Spot size is the affected region or the pattern that the blast stream erodes from a targeted surface. Simply put, the spot size is the etched or cut area surrounded by overspray.

Read more

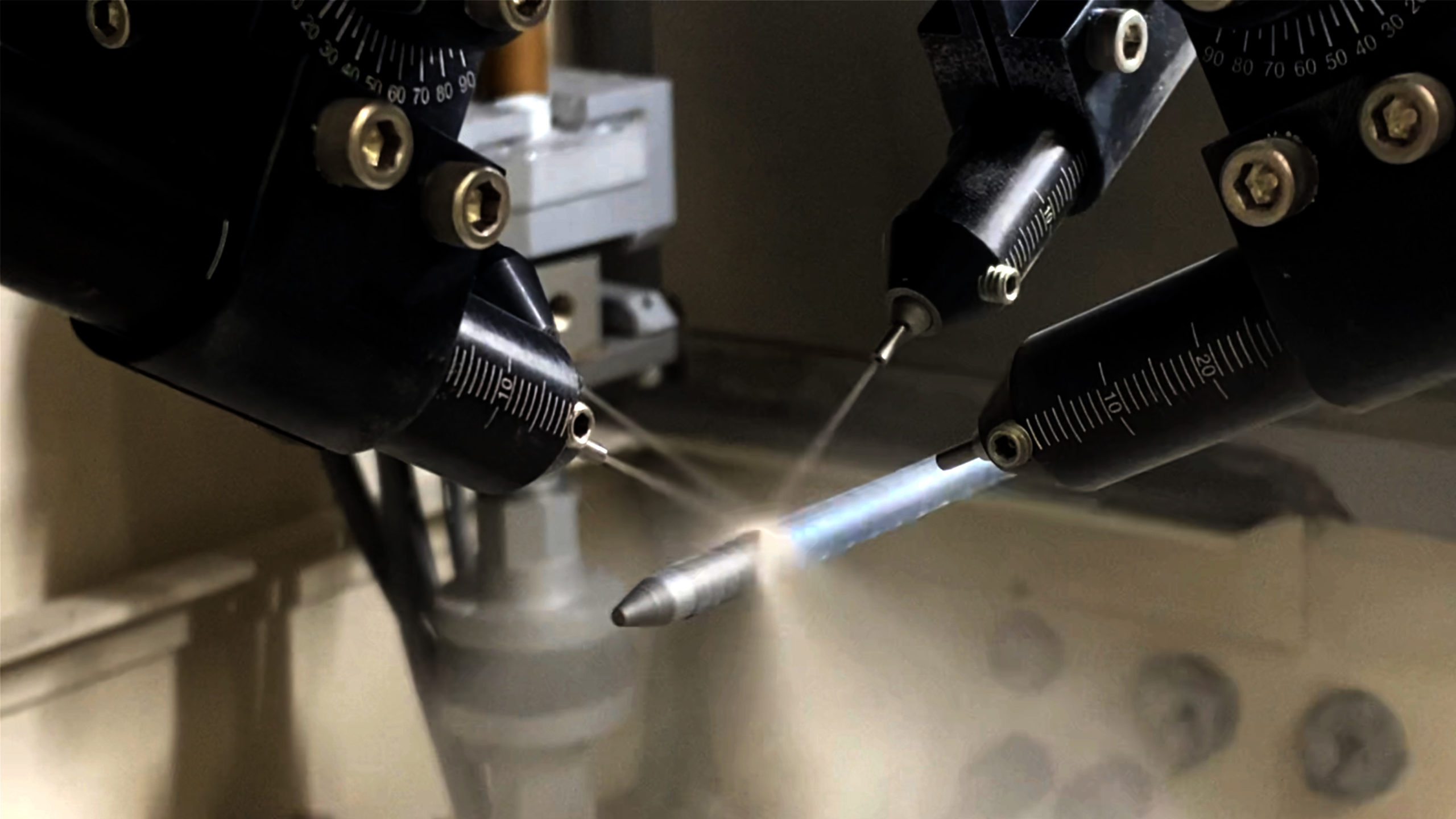

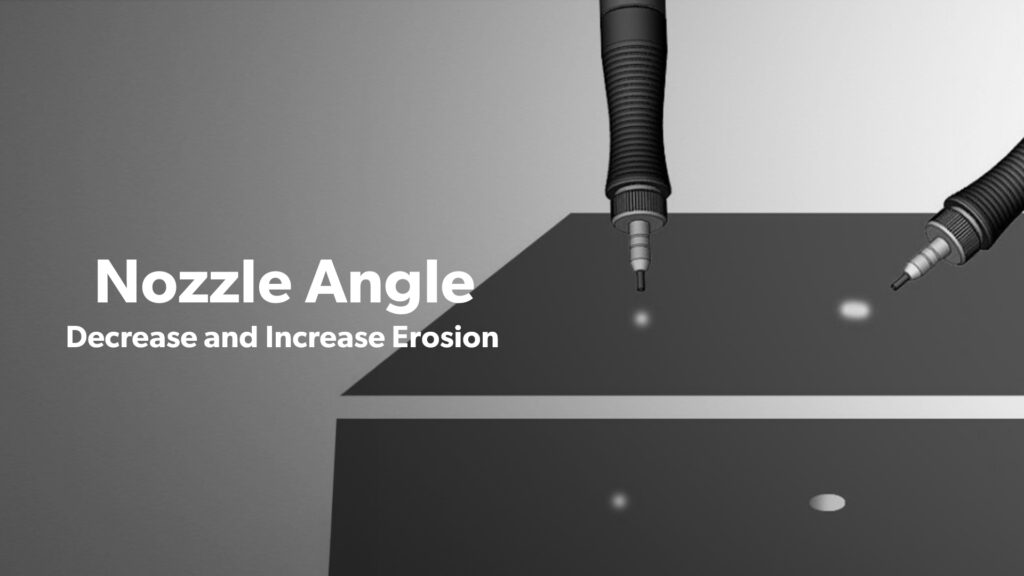

Nozzle Angle

Abrasive particles transfer the most impact energy when the nozzle is positioned at 90° to the target, but abrasive particles ricochet at this direct angle, crowding and slowing the stream. When cleaning or eroding surface material, hold the nozzle at or near a 75° angle to the target.

Read moreThe Manual System

The AccuFlo® produces a steady flow of abrasive which ensures consistent results. It processes parts faster than most traditional micro-abrasive blasters, and it does so with greater powder efficiency. The AccuFlo is able to handle a wide-range of abrasives and suits most MicroBlasting applications.

Learn moreAutomated Solutions

When a manual MicroBlasting system cannot provide the output or meet your tolerance requirements; Comco’s automated systems deliver all the benefits of a manual system with greater precision and efficiency. Both the Advanced Lathe and the JetCenter are designed for the steady processing of precision parts. Each automated system is customizable from a proven platform and delivered as a turnkey solution.

Learn moreWhy Choose Comco?

Do you know what sets a Comco micro-precision sandblaster apart from others? In short, It’s our modulator. This pulsing heart of our system transforms the technology from a dirt sprayer into a precision tool.

Learn more

MicroBlasting Capabilities Proven

-

An Experienced & Qualified Team

Engineers lead the process from concept to development. Our focus is on ensuring the process will work in production. We are as good at figuring out new applications as demonstrating what we have already done.

-

Our State-of-the-Art Lab

Our lab contains a complete range of MicroBlasting tools—from our manual stations to the fully programmable automated systems to run your samples. In addition, we have a complete inspection suite to document our results.

-

Comprehensive Results Ready for You

All results are captured in a clear and detailed report with pictures that you can take right back to your team along with the finished part.

-

Applied Engineering With a Deep Understanding of Industrial Manufacturing

Our engineers have a background in medical, aerospace, and the semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

TRY OUR PROCESS

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a Demo