Equipment Updates

ProCenter Plus Update

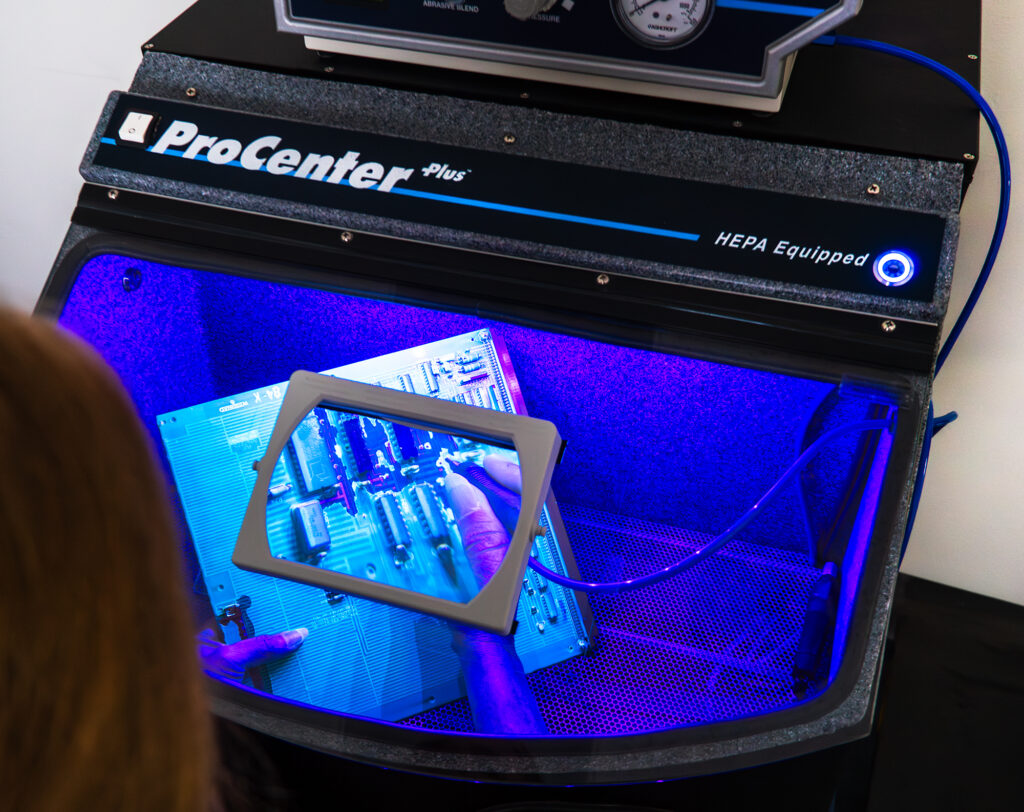

When we introduced the ProCenter Plus in 2011 it quickly became the most popular companion to all of our blasters. Why? This compact, chair-height workstation with an integrated dust collection system and an attached air dryer just makes life easier. It confines the blast area while a built‐in HEPA‐equipped dust collector extracts spent abrasive. It is easy to use and easy to maintain and its sleek, compact design fits easily into your workspace.

What’s new?

Better illumination

The new LED lighting illuminating the work area is what users will notice and appreciate most.

Improved airflow

We’ve also improved the air jets to keep spent abrasive flowing through the floor of the workstation to the HEPA filter keeping your work area clean.

streamlined electrical connections

Thanks to user feedback, we’ve streamlined the placement of switches and power connections to keep things running smoothly. This also includes updates to the internal electrical components.

ESD Control Improvements

We’ve also made improvements to our ProCenter Plus ESD Control models for static sensitive applications:

Easily switch BETWEEN white and black lights

Dual LED light sources installed make working on boards with different coatings easier. View coatings seen more easily under black light with the touch of a button. Then just as easily switch back to white lights as needed for other boards.

Grounded ComfortGrip® handpiece

When paired with the AccuFlo, the new ProCenter Plus ESD Control models now come equipped with a grounded ComfortGrip® handpiece, an ergonomically designed stylus that reduces operator fatigue and improves dexterity. The streamlined design reduces wear points and uses our more focused and wear-resistant AccuFlo nozzles. Previously only available for AccuFlo standard manual applications, we’re pleased to finally make the ComfortGrip® handpiece available in a grounded model for those working with static-sensitive applications.

Applications Lab

Let our experts help find the right solution for your part. We know no two applications are the same. Our Technical Specialists manage sample-part testing and processing from start-to-finish. They actively collaborate with our Sales and Engineering Teams while remaining completely accessible to you throughout the process.