Maintenance & Troubleshooting

FAQ Nozzles

A list of Frequently Asked Questions and potential solutions are loosely organized below. Click the question to see its answer in the drop-down box. Please use this as a starting point to perform simple maintenance on your own and to better understand your Comco equipment.

If you need further assistance, please call 1-818-841-5500 or contact our Technical Support Team by email.

What is the interval for nozzle replacement?

Nozzle wear is process specific. Blast pressure, abrasive type, nozzle type, and blast duration contribute to wear. For example, if you are blasting 50-micron aluminum oxide between 60-90 psi (standard rate) through a Comco Hi/Performance nozzle, then you will probably need to replace the nozzle after using approximately 100-150 pounds of abrasive.

Use a pin gauge to measure to the nozzle opening. If results need to be precise, replace the nozzle when the opening grows by 10%. If your results do not need to be precise, replace the nozzle when the opening has grown by 15%.

Be sure to check out this post with video for more details on how to test for nozzle wear.

Can I blast without a nozzle?

No.

If you need to cover a wide swath of material or douse a part surface in abrasive, it seems logical to remove the nozzle and blast away. But the abrasive hose isn’t like a garden hose. The nozzle on a Comco blaster does more than focus and funnel the abrasive stream, it helps keep abrasive moving at a consistent and regulated pace throughout the machine.

Removing the nozzle increases the velocity of the abrasive stream inside the blaster. The resulting surge is hard to control both inside and outside of the blaster. Abrasive moving at high velocities inside the blaster speeds up wear and tear on the handpiece threads, the abrasive hose, and the PowderGate or pinch valve.

Use a larger tank orifice and potentially a larger nozzle. Consult our Sales Team to get the right configuration. Call 1-818-841-5500 or Contact Us to start the conversation.

Should the nozzle and tank orifice be the same size?

The opening at that bottom of the abrasive tank should always be smaller than the nozzle. Abrasive can’t do its work when the stream is that crowded. If you need more abrasive in the stream, use a larger tank orifice, and if needed, a larger nozzle.

Consult our Sales Team to get the right configuration. Call 1-818-841-5500 or Contact Us form to start the conversation.

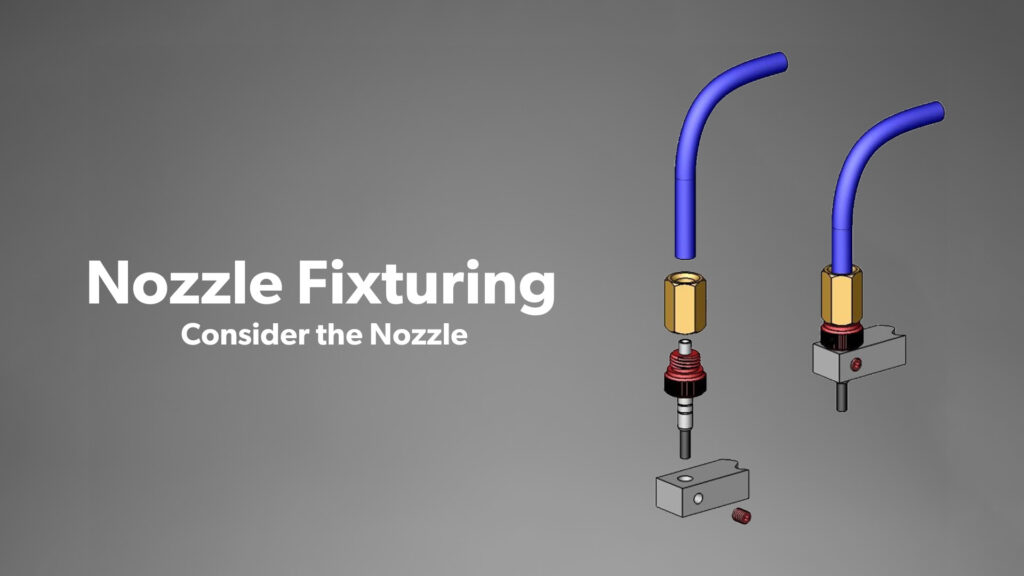

What types of nozzles are available?

Our nozzles come in an array of shapes and sizes for a wide range of applications.

- The straight, round style nozzle with openings ranging from 0.015″ to 0.125″ meets most application requirements.

- Rectangular nozzles are available for applications that require a wide sweep or fan of abrasive.

- Comco’s Hi/Performance nozzles outlast our standard nozzles and deliver an accelerated abrasive flow with a tighter focus, resulting in less overspray.

- Custom nozzles

Read more about Comco Nozzles on the Nozzle page.

For specific part numbers and sizes, click here.

How do I order nozzles?

Contact Comco Customer Service at 1-818-841-5500, by email or fill out the quote request form.